с 01.01.2004 по 01.01.2007

Калининградская область, Россия

Калининград, Калининградская область, Россия

Россия

Некондиционная икра трески, судака и минтая с различной степенью зрелости была использована в качестве сырья для приготовления икорных рыбных изделий. Сущность технологии икорных рыбных изделий заключалась в отделении ястычной пленки от икорного сырья с последующим его нагревом до 80 °С и смешиванием с коллагенсодержащей добавкой (КД), полученной из чешуи судака. Образовавшуюся смесь далее охлаждали до 50 °С, в полученную икорную массу добавляли различные ингредиенты и гомогенизировали, далее однородную смесь расфасовывали в стеклянные банки, герметично закрывали крышками, охлаждали и хранили при температуре 4 ± 2 °С в холодильнике. С целью оптимизации условий получения и улучшения качества готовой икорной продукции были разработаны рецептуры с внесением различных добавок, таких как креветка, соленый огурец, красный перец, копченая паприка, укроп, авокадо, майонез и др. Согласно разработанным рецептурам выработаны опытные партии образцов из различного вида икорного сырья и массовым соотношением (гидромодулем) КД и добавленной воды (используемой в процессе обработки для предотвращения налипания икорной массы к стенкам емкости при термической обработке, а также для улучшения качественных характеристик готовой продукции) в диапазоне от 1 : 4 до 1 : 10, где доля икорного сырья, соответственно, составила от 60,7 до 4,5 %. Исследованы реологические (динамика погружения конуса пенетрометра), а также органолептические характеристики образцов готовой икорной продукции. Экспериментально определено, что оптимальным гидромодулем (КД : добавленная вода), способствующим улучшению качественных характеристик (более нежная консистенция, привлекательный внешний вид и вкус) готовой рыбной икорной продукции, является соотношение 1 : 10.

икорные рыбные изделия, коллагенсодержащая добавка, икра трески, икра судака, икра минтая

Introduction

Caviar fish product is a food fish product made of whole or cut into pieces of caviar or from fish roe, mollusks and echinoderms, with the addition of components of food products (food ingredients), ready for consumption [1].

Due to the non-simultaneous maturation of different populations of pollock and, as a consequence, the delay in spawning time, in the process of its processing a significant amount (up to 40% of the total mass of eggs) of substandard caviar of different maturity levels is formed, characterized by the “fluidity” of the eggs [2]. The use of substandard pollock roe to produce traditional pierced caviar is inexpedient due to the significant losses of raw materials, so the optimal way of its processing is the production of caviar pastes or emulsions. Various hydrocolloids of vegetable or animal origin are used to bind “excess” liquid in the production of fish and caviar pastes and emulsions.

The technology of paste from substandard pollock roe (5th stage of maturity) with the use of sodium alginate (with a molecular weight of about 20 kDa as a gelatin-forming agent (optimally 4% of the total mass of the roe) is known, and flavoring additives (vegetable oil – 5.0%, salt – 2.5%, sugar – 1.0%) and preservative (sodium benzoic acid – 0.1%), with a shelf life of 4 months, at temperatures from –6 ºC to –8 ºC [3].

Significant cost of the used plant hydrocolloids with high molecular weight, which have little nutritional value (no or low protein content), as well as low flavor characteristics of the resulting finished products, limit the production of fish and caviar pastes on an industrial scale.

An economically acceptable technology of high-molecular collagen-containing additive (CA) from underutilized fish scales (without the use of hydrolysis process) based on simple physical methods of processing has been developed [4, 5]. Containing additive has been used as a component of formulations in the preparation of various food products (bakery products, culinary semi-finished products, meat and fish minced meat, food dispersions, etc.) [6-10].

Involvement in industrial production of substandard roe of pollock, cod, pike-perch and their waste, as well as CA from underutilized fish scales will contribute to reducing the deficit of dietary protein, expanding the range of new products with a functional orientation and reducing the ecological load on the environment.

The use of CA in paste formulations based on substandard roe of pollock, cod and pikeperch, taking into account the significant amounts of low-utilized raw materials formed in the process of fish cutting, is of considerable practical interest.

The aim of the work is to develop technology and recipes of caviar fish products obtained from cod, pikeperch and pollock caviar of different maturity levels with the use of CA from pikeperch scales.

To achieve the goal the following tasks were solved:

– development of technology of caviar fish products with the use of CA applied to different types of caviar raw materials;

– production of pilot batches of samples according to the developed technology from caviar raw materials of different fish species;

– development of recipes of caviar fish products with CA;

– study of the influence of CA on rheological and organoleptic properties of finished fish caviar products.

Materials and methods

Raw materials for caviar fish products were substandard frozen pollock roe and chilled cod and pikeperch roe of different maturity levels. As an additive to the raw material was used CA from pikeperch scales (insoluble in water) with a total chemical composition: water – 9.8%; protein – 71.2%; ash – 24.0%; fat – 1.7%. The appearance of CA obtained in laboratory conditions is presented in Fig. 1.

Fig. 1. Appearance of collagen supplement (CA) from pikeperch scales

The material for research were also experimental samples of caviar fish products with the addition of the following ingredients: food salt of the highest grade according to SS R 51574-2018 “Food salt. General technical conditions”; citric acid according to SS 908-2004 “Food citric acid monohydrate. Technical conditions”; avocado according to SS 34270-2017 “Fresh avocado fruit. Technical conditions”; pickled cucumber according to SS 34220-2017 “Pickled and sour vegetables. Technical conditions”; mayonnaise Sloboda Provençal 67% according to SS 31761-2012 “Mayonnaise and mayonnaise sauces. General technical conditions”, fresh dill according to SS 32856-2014 “Fresh dill. Technical conditions”, red pepper according to SS 34325-2017 “Sweet pepper fresh. Technical conditions” and seasoning “Paprika with smoke” according to TC 9199-022-57097479-11.

The total chemical composition of the control sample of cod caviar fish products with CA and CA additive was determined in the certified testing laboratory Kaliningrad Testing Center LLC in accordance with the normative documentation: SS 7636-85 (mass fraction of moisture, protein, fat, ash); MG No. 4237-86 from 29/12/86 (mass fraction of carbohydrates); SS 26188-2016 (determination of pH); TR TS 022/2011 Annex 4, MG No. 4237-86 from 29/12/86 (energy value) [11-14]. Atomic absorption spectrometry was used for calcium determination, and for phosphorus – spectrophotometry with molybdenum ammonium oxide in the presence

of hydroquinone and sodium sulfite.

Penetration of experimental samples of caviar fish products with CA from cod and pollock caviar was determined according to SS R 50814-95 “Meat products. Methods for determining penetration by cone and needle indenter”.

Organoleptic evaluation of experimental samples of caviar fish products with CA was determined by color, smell, taste, consistency by standard and generally accepted methods [15].

The experiments were carried out in the laboratory of the Department of Food Technology of Kaliningrad State Technical University.

Results and discussion

In the process of research, a technological scheme for the production of caviar fish products with CA was developed, presented in Fig. 2.

Fig. 2. Technological scheme of caviar fish products production with CA

According to the technological scheme (Fig. 2) and the recipe of caviar product (cod roe 58.7 g, water – 27.0 g, salt – 0.8 g, KD – 11.5 g, mayonnaise – 2 g, at a mass ratio of CA : water (1 : 4)) was produced a pilot batch of caviar fish product appearance of which is shown in Fig. 3.

The total chemical composition (including phosphorus, calcium, caloric content and pH) of the experimental sample of caviar fish product (from cod roe) with the addition of CA is presented in Table 1.

Fig. 3. Appearance of a prototype of caviar product (cod) with CA

Table 1

|

Food product |

Mass fraction, % |

рН |

Caloric value, kcal/100g |

||||||

|

water |

protein |

fat |

carbohydrates |

ash |

Ca |

P |

|||

|

Caviar product (cod) |

72.6 ± 5.8 |

15.8 4 ± 2.38 |

2.6 ± 0.4 |

4.7 |

4.23 ± 0.01 |

159.8 ± 15.5 |

1.156 ± 0.069 |

5.97 ± 0.24 |

102.2 |

At temperatures above 30 °C, caviar fish product had mobility “fluidity” (which is convenient when pouring caviar mixture into glass jars), and at lower temperatures (4 ± 2 °C) lost mobility, its consistency significantly thickened (gelatinized). The finished product held its shape, had a yellowish-cream color, rather dense consistency and elasticity, taste peculiar to caviar, but with less perceptible “bitterness”, compared to the original caviar without additive (control).

The developed technology (Fig. 1) was also used in the production of caviar products from substandard pikeperch caviar (Table 2).

Table 2

Recipes of caviar products (pikeperch) with CA (with hydromodule CA : water 1 : 5.5)

|

Ingredients |

Weight (samples), g |

||||||

|

Control |

No. 1 |

No. 2 |

No. 3 |

No. 4 |

No. 5 |

No. 6 |

|

|

Pikeperch caviar |

60.7 |

57.8 |

50.6 |

46.7 |

55.3 |

57.8 |

59.5 |

|

Water |

26.7 |

25.5 |

22.3 |

20.6 |

24.3 |

25.5 |

26.2 |

|

Salt |

0.8 |

0.7 |

0.6 |

0.7 |

0.8 |

||

|

CA |

11.5 |

10.9 |

9.6 |

8.9 |

10.4 |

10.9 |

11.2 |

|

Сaviar base: |

99.7 |

95.0 |

83.2 |

76.8 |

90.7 |

95.0 |

99.7 |

|

citric acid; |

0.3 |

0.2 |

0.3 |

||||

|

dill; |

– |

4.7 |

– |

||||

|

avocado; |

– |

16.6 |

– |

||||

|

prawn; |

– |

23.0 |

– |

||||

|

рickled cucumber; |

– |

– |

9.0 |

– |

|||

|

ground red pepper; |

– |

4.7 |

– |

||||

|

smoked paprika |

– |

– |

2.0 |

||||

|

Output finished product |

100.0 |

||||||

The amount of added water was increased in the recipe (Table 2), where the mass ratio of CA : water was 1 : 5.5 and flavoring additives were used.

The obtained caviar fish products were evaluated by organoleptic indicators: appearance (color and size of the ingredients and caviar base, uniformity of their distribution), taste, smell, consistency (Fig. 4-6).

Fig. 4. Appearance of ready-made caviar products (pikeperch) with CA and additives, hydromodule

CA : water 1 : 5.5 (1 – prawn; 2 – pickled cucumber; 3 – red pepper; 4 – smoked paprika; 5 – dill; 6 – avocado)

Fig. 5. Appearance of ready-made caviar products

(pikeperch) with CA and additives: control; 1 – smoked paprika; 2 – prawn;

3 – pickled cucumber; 4 – avocado; 5 – red pepper; 6 – dill

Fig. 6. Organoleptic profile of experimental caviar products (pikeperch) with CA

All samples of caviar fish products had an attractive appearance, dense and elastic consistency, and retained their shape. Рroduct sample No. 6 had a pleasant greenish color and a more delicate consistency similar to pate due to avocado. Sample No. 1 had an orange color due to the addition of smoked paprika. The control, samples No. 2, 3, 5 and 6 were cream-colored with the incorporation of various ingredients according to the recipes (Fig. 4). Taste and odor were typical of caviar fish products with the taste and aroma of the added ingredients, without extraneous taste and odor except for the sample with added shrimp and paprika. The flavor of shrimp was not perceived in the sample, while paprika was pronounced. As a result of the conducted organoleptic studies, it was found that the maximum number of points was scored by samples No. 2, 4 and 6. The consistency of all caviar fish products was quite dense, which was noted by tasters.

The addition of citric acid in the formulation is associated with its preserving properties, and improvement of organoleptic parameters of finished caviar products.

Rheological properties of experimental samples of caviar fish products with mass ratio of CA : water 1 : 5.5 at different storage temperatures were also investigated. The appearance of the penetrometer with the sample before cone immersion is shown in Fig. 7.

Fig. 7. External view of the penetrometer with the sample before immersion of the cone

Penetration values were calculated based on the depth of immersion of the cone (mm) in the control and experimental product samples for 180 seconds.

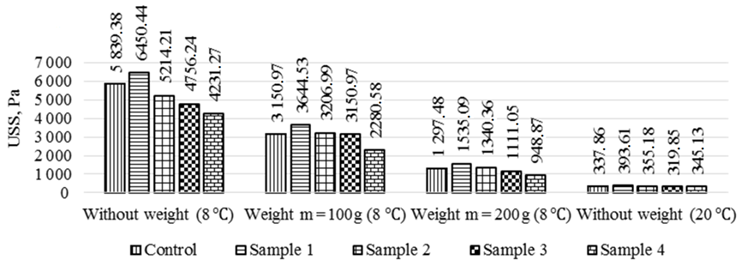

Table 3 and Fig. 8 show the changes in shear strength of experimental samples with hydromodule 1 : 5.5 as a function of storage temperature characterized by penetrometer immersion depth and ultimate shear stress (USS).

Table 3

Dynamics of cone immersion in control and experimental samples of caviar product (pikeperch)

with CA for 180 seconds, at hydromodule CA : water 1 : 5.5

|

Samples of caviar fish products |

Dynamics of cone immersion, mm, at product temperature |

|||

|

20 ºС |

8 ºС |

|||

|

Without weight |

Weight m = 100 g |

Weight m = 200 g |

||

|

Control |

22.67 ± 1.0 |

8.65 ± 0.6 |

12.47 ± 0.2 |

14.51 ± 0.5 |

|

No.1 |

21.90 ± 2.1 |

8.9 ± 0.8 |

12.6 ± 1.2 |

14.99 ± 0.6 |

|

No. 2 |

23.60 ± 1.4 |

8.9 ± 0.8 |

12.44 ± 0.2 |

14.8 ± 1.2 |

|

No. 3 |

23.00 ± 1.2 |

9.05 ± 0.8 |

12.49 ± 0.4 |

14.2 ± 1.2 |

|

No. 4 |

22.07 ± 1.1 |

8.8 ± 0.8 |

12.77 ± 0.8 |

14.53 ± 1.6 |

|

No. 5 |

22.24 ± 2.1 |

9.0 ± 0.8 |

12.57 ± 0.6 |

14.6 ± 2.0 |

|

No. 6 |

22.90 ± 1.4 |

8.9 ± 1.2 |

12.67 ± 0.3 |

14.6 ± 2.0 |

Fig. 8. Variation of USS of caviar samples (pikeperch) with CA,

with hydromodule CA : water 1 : 5.5, as a function of temperature

When the temperature was reduced from 20 to 8 °C, the shear strength of all experimental samples increased and the immersion depth of the pinetrometer cone decreased (Table 3, Fig. 8).

Taking into account the tasters' wishes, in order to give a more “delicate” consistency to the product samples, taking into account the moisture content in the caviar and the added water (hydromodule), the ratio of CA : water 1 : 6.5 was taken in the control and experimental samples (Fig. 9).

Fig. 9. Finished samples of caviar products (pollock) with CA and hydromodule CA: water 1 : 6.5:

1 – control; 2 – No. 1; 3 – No. 2; 4 – No. 3; 5 – No. 4; 6 – No. 5

Water was added when heating the caviar raw material in order to prevent it from sticking to the walls of the container and to better mix the recipe components. Further, when developing caviar fish products, it was taken into account that when adding an ingredient (avocado) containing fat (sample No. 4), the finished product has a more delicate consistency compared to other samples. Later, a small amount of mayonnaise was added to the recipes (Table 4).

Table 4

Recipes of caviar products (pollock) with CA, at hydromodule CA : water 1 : 6.5

|

Ingredients |

Weight (samples), g |

||||

|

Control |

No. 1 |

No. 2 |

No. 3 |

No. 4 |

|

|

Pollock caviar |

30.4 |

25.3 |

27.7 |

27.6 |

|

|

Water |

57.0 |

47.5 |

51.9 |

51.8 |

|

|

Salt |

0.8 |

0.7 |

|||

|

CA |

11.5 |

9.6 |

10.4 |

||

|

Сaviar base: |

99.7 |

83.1 |

90.7 |

90.5 |

|

|

avocado; |

– |

16.6 |

– |

||

|

mayonnaise; |

– |

9.0 |

|||

|

pickled cucumber; |

– |

9.0 |

– |

– |

|

|

smoked paprika; |

– |

0.2 |

|||

|

citric acid |

0.3 |

||||

|

Output finished product |

100.0 |

||||

Samples of finished caviar products with CA are presented in Fig. 9.

The obtained samples of caviar fish products were evaluated by organoleptic parameters: appearance (combination of color, size of ingredients and caviar base, uniformity of their introduction), taste, smell, consistency. All samples of caviar fish products had an attractive appearance, were dense, elastic consistency, retained their shape. The consistency was less dense compared to samples with hydromodule 1 : 5.5. Moreover, samples with mayonnaise had a more tender consistency compared to samples without mayonnaise. In terms of taste, smell and color, all samples except the control were highly rated by tasters. The control had excessive “dryness” of the caviar product.

Changes in shear strength of experimental samples depending on storage temperature with hydromodule CA : water 1 : 6.5 are presented in Table 5 and Fig. 10.

Table 5

Dynamics of cone immersion in control and experimental samples of caviar product (pollock)

with CA for 180 seconds, at hydromodule CA : water 1 : 6.5

|

Samples of caviar fish products |

Dynamics of cone immersion, mm, at product temperature |

|||

|

8 ºС |

20 ºС |

|||

|

Without weight |

Weight m = 100 g |

Weight m = 200 g |

Without weight |

|

|

Control |

10.3 ± 0.8 |

11.4 ± 0.3 |

12.4 ± 1.0 |

18.3 ± 0.5 |

|

No. 1 |

9.8 ± 1.0 |

11.1 ± 0.4 |

11.4 ± 1.0 |

20.5 ± 0.6 |

|

No. 2 |

10.9 ± 0.6 |

11.3 ± 0.6 |

12.2 ± 0.8 |

18.2 ± 0.8 |

|

No. 3 |

11.9 ± 1.2 |

12.4 ± 1.0 |

14.4 ± 2.0 |

30.1 ± 0.8 |

|

No. 4 |

12.1 ± 0.8 |

13.4 ± 0.8 |

14.5 ± 2.1 |

24.9 ± 1.2 |

Fig. 10. Variation of USS of caviar products samples (pollock)

with CA, at hydromodule CA : water (1 : 6.5), depending on temperature

Table 5 and Fig. 10 show that samples with mayonnaise had the greatest depth of cone immersion compared to other samples, which is consistent with their organoleptic characteristics (more tender consistency).

Due to a slightly increased density and elasticity (noted by tasters), a pilot batch with a hydromodule of CA : water 1 : 10 was developed. Recipe and appearance of caviar products samples (pollock) with CA, with hydromodule CA : water 1 : 10 are presented in Table 6 and Fig. 11.

Table 6

Recipe of caviar products (pollock) with CA, at hydromodule CA : water 1 : 10

|

Ingredients |

Weight (samples), g |

|

|

Control |

Sample No. 1 |

|

|

Pollock caviar |

4.9 |

4.5 |

|

Water |

85.4 |

77.6 |

|

Salt |

0.8 |

0.7 |

|

CA |

8.6 |

7.9 |

|

Сaviar base: |

99.7 |

90.7 |

|

citric acid; |

0.3 |

|

|

mayonnaise |

– |

9.0 |

|

Output finished product |

100.0 |

|

а b

Fig. 11. Appearance of samples of ready caviar products (pollock) with CA, at hydromodule CA: water 1 : 10:

a – control; b – sample No. 1

Fig. 11 shows that the caviar base from pollock caviar and caviar base with mayonnaise (10% to the caviar base weight) with hydromodule CA : water (1 : 10), also retained their shape, but had a more delicate consistency similar to the consistency of soufflé. When chewed, the samples quickly melted in the mouth. The most delicate consistency and homogeneous structure had samples with the addition of mayonnaise. Based on the above, the amount of added water can be increased to the ratio of CA : water 1 : 10.

Conclusion

Addition of CA, allows to level excessive “bitterness” characteristic for caviar products, as well as inherent in caviar “dryness” (in the absence of oil addition), and to give the finished product a sufficiently attractive (tender) consistency, allowing to distribute it evenly on a sandwich while maintaining the shape.

It has been experimentally determined that to obtain caviar fish product with tender consistency and homogeneous structure the mass ratio (hydromodule) of CA and water should be 1 : 10.

Innovativeness and commercial attractiveness of the developed technology of caviar fish products consists in the use of two sources of raw materials (substandard caviar and CA from fish scales) insufficiently used on an industrial scale, the involvement of which, in an economically acceptable way, in the industrial production of food products will allow to obtain protein delicacy products of functional orientation with high added value, to reduce environmental pollution by fish waste due to their effective food processing.

1. О безопасности рыбы и рыбной продукции: технический регламент Евразийского экономического союза ТР ЕАЭС 040/2016 от 18 октября 2016 г. № 162. URL: https://docs.cntd.ru/document/420394425 (дата обращения: 06.03.2024).

2. Калиниченко Т. П. Технология производства пас-ты из некондиционной икры минтая // Рыбное хозяйство. 2001. № 5. C. 50–51.

3. Калиниченко Т. П. Разработка технологии слабосоленой пасты из некондиционной икры минтая // Изв. ТИНРО. 2001. Т. 129. С. 304–311.

4. Воробьев В. И., Нижникова Е. В. Получение фракций коллагена и гидроксиапатита из рыбьей чешуи // Изв. Калинингр. гос. техн. ун-та. 2021. № 62. С. 80–91. DOI:https://doi.org/10.46845/1997-3071-2021-62-80-91.

5. Способ обработки рыбьей чешуи для получения коллагена и гидроксиапатита: вылож. заявка РФ 2021116247 / Воробьев В. И.; заявл. 03.06.21, опубл. 05.12. 22. Бюл. 34.

6. Пат. РФ 2806832. Панировочная смесь / Воробьев В. И., Чернега О. П., Нижникова Е. В.; заявл. 03.02.23; опубл. 08.11.23. Бюл. № 31.

7. Пат. РФ 2787112. Способ получения пищевой дисперсии / Воробьев В. И., Чернега О. П.; заявл. 21.02.22; опубл. 28.12.22. Бюл. № 1.

8. Воробьев В. И., Чернега О. П., Берсенева А. Р. Применение коллагена гидробионтов в производстве продукции на основе рыбного фарша // Вестн. Воро-неж. гос. ун-та инженер. технологий. 2022. Т. 84. № 2. С. 84–92. http://org/10.20914/2310-1202-2022-2-84-92

9. Воробьев В. И., Чернега О. П., Яковлева М. В. Разработка коллагенсодержащего икорно-майонезного соуса в рецептуре пресервов «Сельдь атлантическая» // Изв. Калинингр. гос. техн. ун-та. 2023. № 69. С. 59–73. DOI:https://doi.org/10.46845/1997-3071-2023-69-59-73.

10. Воробьев В. И., Чернега О. П. Получение пищевых дисперсий с использованием высокомолекулярного коллагена чешуи рыб // Изв. Калинингр. гос. техн. ун-та. 2023. № 68. С. 71–79. DOI:https://doi.org/10.46845/1997-3071-2023-68-71-79.

11. ГОСТ 7636-85. Рыба, морские млекопитающие, морские беспозвоночные и продукты их переработки. Методы анализа. М.: Стандартинформ, 2010. 123 с.

12. МУ № 4237-86. Методические указания по гигиеническому контролю за питанием в организованных коллективах. М.: Минздрав РСФСР, 1986. 25 с.

13. ГОСТ 26188-2016. Продукты переработки фруктов и овощей, консервы мясные и мясорастительные. Метод определения рН. М.: Стандартинформ, 2019. 17 с.

14. Технический регламент Таможенного Союза ТР ТС 022/2011 от 9 декабря 2011 г. № 881. Приложение 4. URL: https://www.novotest.ru/tr-ts/022-2011/ (дата обращения: 06.03.2024).

15. ГОСТ 31986-2012. Услуги общественного питания. Метод органолептической оценки качества продукции общественного питания. М.: Стандартинформ, 2019. 12 с.