Россия

Снековая продукция, в том числе рыбные снеки, составляющие значительную ее долю, в последние годы на российском рынке приобретают все большую популярность. В связи с возросшим спросом расширяется ассортимент, развиваются и совершенствуются технологии производства данного вида продуктов. Особую категорию рыбной снековой продукции составляют сыровяленые и сырокопченые колбасы, являющиеся аналогом подобных мясных изделий, вкусовые качества, аромат и консистенция которых обеспечиваются за счет биохимических процессов распада белков и липидов под действием ферментов или микроорганизмов. Целью данного исследования являлось изучение процесса созревания мышечной ткани толстолобика. На первом этапе исследования изучено влияние ферментов мышечной ткани на кинетику накопления продуктов гидролаз в мышечной ткани толстолобика при значениях рН 4,5–6,5 ед. Установлено, что в диапазоне 4,5~5,5 рН активность протеолитических ферментов наибольшая за счет действия катепсинов. На втором этапе исследования было изучено влияние массовой доли комплексной пищевой добавки «РУТАФИШ Мирсол БС» на процесс созревания мышечной ткани толстолобика при естественном значении рН 6,5 ед. Скорость гидролиза для образцов с содержанием до-бавки 1,2–1,8 % была в пределах 0,42–0,46 ед. акт. и находилась в пределах относительной погрешности, поэтому оптимальной для использования в производстве сыровяленых и сырокопченых рыбных колбас является массовая доля комплексной пищевой добавки 1,2 %, и дальнейшее увеличение содержания добавки нерационально. Третий этап исследования заключался в изучении возможности совместного действия рН среды и созревателя на гидролизуемость мышечной ткани толстолобика. Установлено, что при совместном действии этих двух факторов появляются две зоны оптимума рН, равные 4,5 и 6,5 ед. и соответствующие зонам оптимумов катепсинов мышечной ткани (4,5~5,5 рН) и ферментов, содержащихся в добавке «РУТАФИШ Мирсол БС» и способных расщеплять белок при естественных значениях рН рыбы.

созревание, толстолобик, формольно-титруемый азот, ферменты мышечной ткани, гидролизуемость

Introduction

In recent years, the domestic market for snack products has been characterized by an increase in the growth rate of cash sales and assortment. The increased demand for this type of product is associated with significant changes in the nutritional structure as a result of the coronavirus pandemic. Restrictions and self-isolation introduced during the pandemic contributed to the development of demand for snack products as a quick snack that does not require additional cooking [1].

Snacks made from fish and seafood make up 7% (27 thousand tons) in volume terms and 10% (25 billion rubles) in value terms of the total volume of the Russian snack market [1]. In the wake of the development of the domestic market for fish snack products, a lot of new technologies and directions for the development of this type of products are emerging, one of which is the use of aquaculture facilities, which, due to the imposed sanctions, reduces dependence on imports, and also helps preserve stocks of the main commercial fish [2].

The range of fish snacks is currently represented by many items. The most common types of finished products are fish chips, crisps, and layers of fillets of small fish species. In addition, dried and raw smoked fish sausages are gaining popularity, which, along with similar meat products, can be used as a quick snack [2]. The key process in the production of this type of product is maturation of fish muscle tissue. Maturation refers to the enzymatic breakdown of proteins and lipids. The result of this biochemical process is the product’s special taste and consistency [3]. Different species of fish are characterized by different maturation abilities, due to the species specificity of the enzyme system and its activity. The enzyme system of fish muscle tissue is mainly represented by enzymes such as cathepsins A, B, C and D. Fish muscle cathepsins differ from the corresponding mammalian enzymes in their more strict specificity of action, as well as higher enzyme activity [4].

For many salted fish snack products, the maturation ability is decisive for the use of a particular fish species. There are various ways to stimulate this process in slow-maturing fish species. Enzyme preparations from the insides of maturing fish species can be used as maturation intensifiers; microbiological synthesis enzymes; acidity regulators that can activate muscle tissue proteases by lowering the pH to 4.5~5.5, or other nutritional additives such as glucono-delta-lactone (E575) and disodium pyrophosphates [5].

The purpose of this study was to study the influence of technological factors on the process of maturation of silver carp muscle tissue. To achieve this goal, the following tasks have been set:

1. To study the influence of environmental pH on the proteolytic activity of silver carp muscle tissue.

2. To study the influence of an enzymatic ripening agent on the process of protein breakdown in silver carp muscle tissue.

3. To study the combined influence of the pH of the medium and the ripening agent on the kinetics of accumulation of hydrolase products in the muscle tissue of fish.

Objects and methods

The objects of the research were the muscle tissue of silver carp (Hypophthalmichthys), which meets the requirements of TR CU 021/2011 and TR CU 040/2016, and a complex food additive called “RUTAFISH Mirsol BS” (TС 10.84.12-003−56746846−14).

The experiments were carried out in the laboratories of the Department of Food Technology at Kaliningrad State Technical University.

To substantiate the effect of pH on the hydrolyzability of silver carp muscle tissue, samples of homogenates have been prepared (muscle tissue : universal buffer solution in a ratio of 1 : 2) with pH = 4.5, pH = 5.0,

pH = 5.5, and a control sample (muscle tissue : distilled water in a ratio of 1 : 2) with pH = 6.5. In order to substantiate the effect of the complex food additive “RUTAFISH Mirsol BS” on the process of muscle tissue protein breakdown, samples of homogenates have been prepared with a mass fraction of the additive of 1.0, 1.2, 1.4, 1.6, 1.8, 2.0%. To substantiate the effect of pH on the maturation of muscle tissue of silver carp containing 1.2% of the Mirsol BS additive, samples of homogenates have been prepared (muscle tissue : universal buffer solution in a ratio of 1 : 2) with a mass fraction of the Mirsol BS additive of 1.2% and with

pH = 4.5, pH = 5.0, pH = 5.5.

The hydrolyzability (activity of proteolytic tissue enzymes) of silver carp muscle tissue has been determined by the intensity of accumulation of formol-titratable nitrogen (mg per 100 g of tissue per minute) in the filtrate after 12 and 24 hours of thermostatting at a temperature of 30 °C and has been expressed as the rate of hydrolysis of muscle tissue proteins in the period when the kinetics of accumulation of hydrolase products is described by a straight line equation and the amount of converted substrate does not exceed 20%.

Mathematical processing of the results has been carried out using the Statistica software package and Microsoft Office 2016.

Results

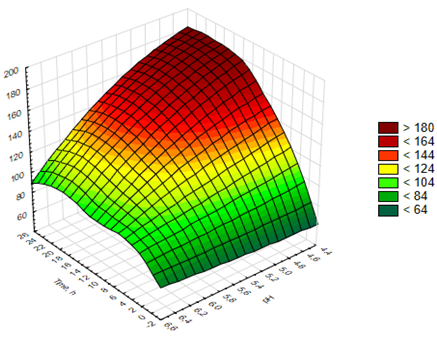

At the first stage of the study, the proteolytic activity of silver carp muscle tissue has been studied, as well as the effect of environmental pH on the amount of broken down protein. Fig. 1 shows a graph of the dependence of the amount of formol titratable nitrogen (FTN) accumulation on the hydrolysis time and pH of the environment.

Fig. 1. Graph of the dependence of the amount of FTN accumulation on time and pH of the environment

As can be seen from Fig. 1, during the first 12 hours of hydrolysis, the increase in FTN was 16.0 mg% for the sample with the natural pH of silver carp muscle tissue (6.5 units), for the sample with

pH 5.5-61.2 mg%, with pH 5.0-75.1 mg% and with pH 4.5-86.9 mg%, in the next 12 hours there was a slowdown in the increase in protein breakdown products by 2.8; 11.1; 11.7; 12.8 mg% respectively.

A decrease in the pH of the environment significantly increased the amount of degraded amino acids and peptides compared to the control sample; therefore, muscle tissue enzymes at natural pH have less proteolytic activity and are not able to sufficiently degrade the substrate. The greatest increase in FTN in the studied range was observed at a pH of 4.5 units. The kinetics of accumulation of hydrolase products in all samples during the first 12 hours of fermentation can be described by a straight line equation; subsequently, the rate of the enzyme reaction and the increase in protein breakdown products reduce significantly.

Fig. 2 shows activity of proteolytic enzymes in muscle tissue.

Fig. 2. Graph of the dependence of the rate of hydrolysis of protein substances

in the muscle tissue of silver carp on the reaction of the environment

The graph in Fig. 2 shows that the rate of hydrolysis of protein substances increases with increasing acidity of the environment. The highest enzymatic activity in the muscle tissue of silver carp in the studied range is observed at pH 4.5-5.5, which is the optimum pH for cathepsin enzymes.

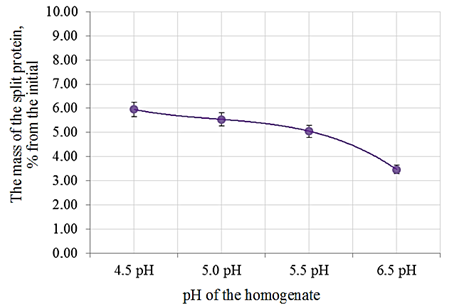

Fig. 3 shows the ratio of the mass of digested protein depending on time and pH of the environment.

Fig. 3. The ratio of the mass of digested protein depending on time and pH of the environment

Graph 3 shows that the mass of digested protein for a sample with a pH of 6.5 units during the first 12 hours of fermentation amounted to 3.47% of the original protein. As the pH of the medium decreases, the ratio of the amount of digested protein to the original protein increases, and for a sample with 4.5 pH the ratio is 5.95%.

The course of the curves shown in Fig. 1-3 correlates in nature with literature data obtained for various fish species [4, 6-8].

Maturation of fish muscle tissue is an important stage in the production of dried fish products. Protein breakdown products (amino acids, peptides, etc.) play an important role in the formation of the taste and aroma of ripe fish [9].

The degree of maturation of silver carp muscle tissue has been determined as the ratio of formol-titrated nitrogen to total nitrogen. The muscle tissue of silver carp can be considered mature, when FTN has reached 10-12% as a percentage of total nitrogen.

Based on Fig. 3, it can be seen that during the first 12 hours of fermentation, FTN reached 5.95% of the total nitrogen for the sample with a pH of 4.5 units, 5.54% for the sample with a pH of 5.0 units and 5.05% – for a sample with a pH of 5.5 units. Consequently, during a day of hydrolysis at an acidic pH, the muscle tissue of silver carp only begins to mature. But with the calculation of the time spent on the production process of dry-cured or raw smoked sausage fish products and its transportation, by the time of sale and subsequent storage period the ratio of FTN to total nitrogen will increase.

Unlike the meat industry, where starter cultures are used to increase the rate of breakdown of meat proteins, fish products traditionally use ripening agents, which may contain enzyme preparations, phosphate additives or acidity regulators [9].

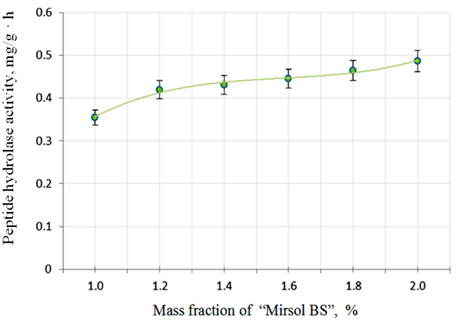

At the second stage of the study, the effect of the complex food additive-maturing agent “RUTAFISH Mirsol BS” on the hydrolyzability of silver carp muscle tissue has been find (Fig. 4, 5).

Fig. 4. Graph of the dependence of FTN accumulation

on time and on the mass fraction of the added food additive “RUTAFISH Mirsol BS”

Fig. 5. Graph of the dependence of the hydrolyzability

of protein substances of muscle tissue on the mass fraction

of the added food additive “RUTAFISH Mirsol BS”

Graphs 4 and 5 show that an increase in the concentration of the ripening agent increases accumulation of protein breakdown products and the rate of hydrolysis at the natural pH value of the ripening agent. As can be seen from graph 5, during the first 12 hours of hydrolysis, the reaction rate for samples with a ripening agent content of 1.2-1.8% was at the same level and within the relative error. Consequently, the mass fraction of 1.2% of the food additive “Mirsol BS” is optimal for use in the production of dried or raw smoked sausage fish products, the technology of which is based on ripening, and a further increase in the concentration of the ripening agent is irrational.

The third stage was to study the possibility of the combined effect of the complex food additive “RUTAFISH Mirsol BS” and the pH of the environment on the biochemical processes of protein breakdown (Fig. 6, 7).

Fig. 6. Graph of the dependence of FTN accumulation

on time and pH of the environment for samples

with a mass fraction of ripening agent of 1.2%

Fig. 7. Graph of the dependence of the rate of hydrolysis

of protein substances on the pH of the medium for samples with a mass fraction of ripening agent of 1.2%

As can be seen from the graphs in Fig. 6 and 7, the maximum amount of FTN is observed in samples with 4.5 and 6.5 pH, and the complex effect of the pH of the medium and the ripening agent slowed down the accumulation of FTN in muscle tissue compared to the data obtained in the first and second stages of the research. The difference in FTN accumulation for the sample at pH = 4.5 and for the control sample with the natural pH of muscle tissue did not exceed the relative error limits. The kinetics of accumulation of hydrolase products during the first 12 hours of fermentation with the addition of the complex food additive “RUTAFISH Mirsol BS” decreased by 28.2% for the muscle tissue sample with 5.0 pH, and by 58.1% for the sample with 5.5 pH.

The obtained result is explained by the fact that enzymes in the muscle tissue of silver carp are largely represented by cathepsins, the optimum pH of which is an acidic environment, while the complex food additive “RUTAFISH Mirsol BS” is capable of breaking down protein at the natural pH value of the muscle tissue of silver carp of 6.5 units. Consequently, with the combined action of acidic pH and the ripening agent, the main influence on the biochemical process of ripening is exerted by cathepsins.

Conclusion

The influence of the pH of the environment and the mass fraction of the complex food additive “RUTAFISH Mirsol BS” on the process of maturation of muscle tissue of silver carp has been studied. It has been established that the kinetics of accumulation of hydrolase products increases with a decrease in pH in an acidic environment and takes the highest values in the pH range of 4.5-5.0 units. (0.31-0.42 active units). The mass fraction of the complex food additive “RUTAFISH Mirsol BS” is substantiated at 1.2%, which is optimal for use in the maturation of fish muscle tissue.

No synergistic effect has been revealed of the pH of the environment and the complex food additive on the kinetics of accumulation of hydrolase products in the muscle tissue of fish. The combined use of acidity regulators and the complex food additive under study is irrational. Depending on the type of finished fish product, it is recommended to use either acidity regulators that reduce the pH of muscle tissue to 4.5-5.0 units, or to use ripeners that act at the natural pH of muscle tissue.

1. Чмыхалова В. Б., Чмыхалов Б. А., Ефимова М. В., Ефимов А. А. Рыбные снеки на основе вторичного высокоминерализованного сырья как перспективная составляющая ассортимента снековой продукции // Вестн. Камчат. гос. техн. ун-та. 2023. № 65. С. 6–17.

2. Мукатова М. Д., Киричко Н. А., Углова Н. Ю., Романенкова Е. Н. Инновационная технология изготовления сырокопченой рыбной колбасы на основе комбинированного сырья // Вестн. Астрахан. гос. техн. ун-та. Сер.: Рыбное хозяйство. 2017. № 4. С. 165–173.

3. Салтанова Н. С., Благонравова М. В. Современные тенденции производства соленой продукции из гидробионтов // Вестн. Камчат. гос. техн. ун-та. 2012. № 20. С. 67–74.

4. Дворянинова О. П. Получение и исследование свойств катепсинов мышечной ткани прудовых рыб // Технологии пищевой и перерабатывающей промышленности АПК – продукты здорового питания. 2014. № 4. С. 14–27.

5. Чернова А. В. Обоснование принципов использования функционально-технологических добавок при производстве пресервов из сельди: дис. ... канд. техн. наук. Калининград, 2013. 229 с.

6. Шендерюк В. И. Производство слабосоленой рыбы. М.: Пищ. пром-сть, 1976. 172 с.

7. Толкачева О. В. Разработка технологии малосоленых пресервов, стойких в хранении при умеренной положительной температуре: дис. … канд. техн. наук. Калининград, 2006. 28 с.

8. Панина М. Н. Разработка технологии малосоленых пресервов из балтийской сельди с использованием ВАД: дис. … канд. техн. наук. Калининград, 2002. 119 с.

9. Сарапкина О. В., Иванова Е. Е. Применение ферментных препаратов для ускорения созревания рыб // Изв. вузов. Пищевая технология. 2006. № 4. С. 58–61.