Калининградская область, Россия

с 01.01.2020 по настоящее время

Калининград, Калининградская область, Россия

Россия

Рассматриваются перспективы применения методов экструзионной обработки продуктов на основе рыбного фарша. Эффективными методами являются методы холодной экструзии и коэкструзии. Целями исследования являются установление теоретических и экспериментальных закономерностей изменения реологических характеристик рыбных фаршей из объектов аквакультуры (карпа, толстолобика) и их анализ применительно к процессам экструзионной обработки. Изучались зависимости реологических характеристик образцов рыбного фарша от влияющих параметров в широком температурном диапазоне, от –5 до +25 С. Величины предельного напряжения сдвига и глубины пенетрации рыбных фаршей определяли на коническом пластометре КП-3; вязкость – на ротационном вискозиметре Брукфильда DV-II+Pro, адгезионную способность – на лабораторной установке для определения липкости материала. Исходя из данных по химическому составу рыбных фаршей получены теоретические зависимости эффективной вязкости от градиента скорости сдвига. Аналогичные зависимости получены экспериментальным путем в широком температурном диапазоне. Анализ данных зависимостей показал их качественное совпадение для обычных условий приготовления фарша, но имеются количественные различия, обусловленные технологией приготовления рыбных фаршей из объектов аквакультуры. Проведен анализ реологических характеристик рыбных фаршей для исследуемого температурного диапазона. Установлено, что область температур от –2,5 С до нуля является наиболее целесообразной для осуществления процессов холодного экструдирования. В этой области значение эффективной вязкости фаршей и ее адгезионной способности являются минимальными, что является определяющим для реализации процессов экструзионной обработки. Отмечена также хорошая формуемость продукта в этих условиях. Дальнейшим направлением исследования является установление влияния технологических добавок на формуемость рыбного фарша из объектов аквакультуры, уменьшение запаха рыбы и устранение нежелательных окислительных процессов. Актуальной остается разработка новых видов рыбных продуктов с инновациями в форме, текстуре, цвете и составе продуктов. Подтверждена перспективность метода коэкструзии, который позволяет создавать новые инновационные рыбные продукты с функциональными свойствами.

рыбный фарш, холодная экструзия, коэкструзия, реологические характеристики

Introduction

The global food industry is experiencing significant growth in extrusion-processed products. Extrusion technologies make it possible to involve underused secondary resources in the food flow. The ability to create products with functional ingredients has led to innovations in the shape, texture, color, and composition of extruded products to meet the growing demand associated with changing lifestyles and preferences [1].

As a method, extrusion is a process of processing products in an extruder by softening or plasticizing and shaping them by forcing through an extrusion die, the crosssection of which corresponds to the configuration of the product [2]. According to the moisture content in raw materials, there are three main ways of extruding food raw materials: cold (W = 30-60%), warm (W = 20-30%), and hot (W = 10-20%). With cold extrusion, only mechanical changes in the material are possible under the influence of pressure and the formation of a product of given dimensions. During warm and hot extrusion, the material is additionally exposed to heat and biochemical changes occur in it.

A variation of the cold extrusion process is co-extrusion, which is the joint extrusion of two food masses, one of which is the casing and the other is the filling of the finished product or semi-finished product. Co-extrusion technology allows one to create a combination of different ingredients by combining products of different nature into a consumer-friendly nutritional product. The progressiveness of this technology is associated with the achievement of a synergistic effect, which consists of the possibility of creating a product balanced in terms of macro- and micronutrients. Due to the variability of ingredients, it becomes possible to create new products belonging to the group of functional products [3, 4].

Co-extrusion methods are increasingly being used in the food industry. It is of interest to use fish raw materials in creating co-extrusion products with a significant potential for functional properties. Finished products have been obtained on the basis of minced fish (cod, catfish, pink salmon, and silver carp) by co-extrusion with wheat, corn, soy, and potato flour. The final product is obtained according to a single technological cycle and subjected to forming without temperature effects; waste-free and environmentally friendly production is ensured [5].

However co-extrusion technologies in the fish market are still at an early stage [6]. The need to develop sensory-acceptable food products based on co-extruded ingredients and the need to eliminate the smell of fish and possible oxidative changes in the product is noted.

One of the tasks of the technology of extrusion processing of food products is to provide the necessary conditions for forming the finished product to give it

a selected shape and structure. The ability of minced fish and minced products to be formed is determined by their elastic, plastic, and viscous properties evaluated by dome rheological indicators [7]. Rheological indicators, such as effective viscosity, ultimate shear stress (USS), and penetration depth, allow one to evaluate the quality of products and implement automatic process control at all stages of production.

It should be taken into account that the ability of food material to form a stable product structure during extrusion processing should be objectively evaluated according to a set of rheological indicators. However, there are no studies on the dynamics of changes in the rheological characteristics of fish raw materials in the temperature range corresponding to cold extrusion [8].

In their research, Yu. A. Fatykhov, V. A. Shumanov, and V. A. Zarudnyi [9] have identified the relationship between the parameters of the process of coextruding high-viscosity food masses and the geometric characteristics of the unit for forming the finished product or semi-finished product. In the case of opening and closing the diaphragm of the co-extrusion nozzle, the formation of each product instance occurs under non-stationary conditions. With known design dimensions of the forming unit of the co-extruder, the process parameters are determined by the viscosity of the ingredients of the food product.

In this regard for the studied types of minced fish in the process of cold extrusion it is necessary to identify the dynamics of changes in viscosity from the shear rate in the temperature range inherent in this extrusion type and to evaluate the influence of other rheological indicators of raw materials.

It is also of scientific interest to use minced aquaculture fish as a research object since according to some authors [1, 3, 5, 10] it is most suitable for obtaining new innovative products by extrusion.

Thus the key issues of this research are as follows:

– to identify patterns of changes in some rheological characteristics of minced fish depending on the influencing factors;

– and to analyze their influence in relation to the possibility of providing the best conditions for product forming during extrusion processing.

In the paper, we consistently describe the following aspects:

– purpose and objectives of the research;

– methodological apparatus used;

– results of a theoretical analysis of the studied types of minced aquaculture fish;

– identification of patterns of changes in the effective viscosity of minced fish from shear rate based on indicators of their chemical composition;

– results of an experimental study of patterns of changes in some rheological indicators of the studied types of minced fish depending on the influencing factors and their analysis;

– comparison of theoretical and experimental data on viscosity characteristics;

– critical discussion of the results obtained;

– and conclusion related to the main scientific findings, practical significance, and prospects for further research.

Materials and methods

The purpose of the research is to identify theoretical and experimental patterns of changes in the rheological characteristics of minced aquaculture fish and to analyze them in relation to extrusion processes.

The objectives of the research are as follows:

– to determine the chemical composition of minced aquaculture fish and, on the basis of its indicators, to identify the theoretical dependence of the effective viscosity of minced fish on the shear rate;

– to identify experimental characteristics of rheological indicators (USS, penetration depth, adhesive ability, and effective viscosity) depending on the influencing factors for the studied types of minced fish;

– to compare the results of theoretical and experimental dependences of the effective viscosity on the shear rate and temperature conditions;

– to analyze the influence of rheological indicators on the conditions of the forming process during extrusion processing;

– to reveal the scientific novelty of the research and to evaluate its practical significance and prospects for further research.

The research objects were frozen silver carp (Hypophthalmichthys) and carp (Cyprinus carpio) corresponding in quality to the current technical documentation GOST 17660-97 [11], the chemical composition (protein, fat, water) of which was determined according to GOST 7636-85 before further research [12].

Before preparing the samples, the frozen carcasses of carp and silver carp were subjected to defrosting and further cutting into skinned fillets. Next the muscle tissue of the fillet was subjected to grinding on a cutter for one minute until a homogeneous mass was obtained.

In order to study the rheological characteristics of minced fish depending on the influence of temperature factors on them (in the range from –5 to +25 °C), samples of freshly mixed minced carp and silver carp were subjected to cooling and further freezing to a temperature up to –5 °C in some samples. In the minced fish samples obtained with a decrease in temperature (in the range of 4 ± 1 °C), the following rheological characteristics were determined:

– USS value;

– penetration depth depending on the immersion time of the penetrometer cone;

– viscosity depending on spindle speed;

– adhesive ability.

The change in the values of the USS and the penetration depth were determined on a conical plastometer KP-3, the viscosity – on a rotational viscometer Brookfield DV-II+Pro, and the adhesion ability – on a laboratory unit for determining the stickiness of the material. When determining the adhesive ability, we placed minced fish samples between two round plates, made of stainless steel with a surface area of 4.84 cm2, before testing and a weight of 1 kg on top of the plate for 5 seconds before measurements.

When determining the indicators of effective viscosity (ηef), we used an RV7 spindle, made of stainless steel of a cylindrical shape with a diameter (d) of 0.0032 m2 and a working surface height (h) of 0.051 m.

Results

Table 1 shows data on the chemical composition of minced carp and silver carp.

Table 1

Chemical composition of minced fish under study

|

Fish type |

Chemical composition, % |

||

|

Protein |

Fat |

Moisture content |

|

|

Carp |

18.2 ± 0.5 |

6.3 ± 0.5 |

73.4 ± 0.2 |

|

Silver carp |

21.2 ± 0.4 |

1.5 ± 0.5 |

75.9 ± 0.2 |

Table 1 shows that according to the moisture content in the studied samples of minced fish it can be used in this form only to obtain a product by cold extrusion. In order to implement other extrusion methods minced fish must be significantly dehydrated which is an energy-intensive and expensive technological operation.

The effective viscosity of minced fish is a variable value that depends on the velocity gradient. For minced fish of one type the degree of its grinding also affects the effective viscosity value. According to the chemical composition of minced fish it is possible to predict the dependence of the change in the effective viscosity of minced fish on the velocity gradient in a given range of its change. For this, the following values are calculated [8]:

– moisture content UW, as the ratio of the moisture content in minced fish W to the moisture content in the dry residue, kg/kg:

– protein content UP, as the ratio of protein mass mP to the total mass without it, kg/kg:

– fat content Uφ, as the ratio of the mass of fat mφ to the total mass of the product without fat, kg/kg:

– chemical composition criterion K:

where P, φ – protein and fat content, respectively, in 1 kg of minced fish, kg/kg;

– complex coefficient of chemical composition:

The results of calculating the indicators of the chemical composition of minced fish under study are shown in Table 2.

Table 2

Indicators of the chemical composition of minced fish under study

|

Fish type |

Chemical composition indicators |

||||

|

UW, kg/kg |

UP, kg/kg |

Uφ, kg/kg |

K |

Ky |

|

|

Carp |

3.56 |

0.222 |

0.067 |

0.812 |

1.146 |

|

Silver carp |

3.15 |

0.267 |

0.015 |

4.489 |

4.787 |

According to the K and Ky values, it is possible to classify [6] minced carp as mince belonging to the third group – mince with a smearing consistency (with a high-fat content), and minced silver carp as mince belonging to the first group – mince with a high stable consistency.

The dependence of the effective viscosity of minced fish on the velocity gradient can be determined by the formula of N. E. Fedorov and A. V. Gorbatov [8]:

where: h – effective viscosity at a single value of the velocity gradient, Pa·s;

The values of h(K) for the respective dependency zones are determined by the following formulas [8]:

– for minced carp:

where A = 650;

– for minced silver carp:

where A = 80.

The rate of destruction of the structure of minced fish is identified as follows:

Let us express Dependence (1), taking into account Formulas (2)–(4) in the explicit form:

– for minced carp:

– for minced silver carp:

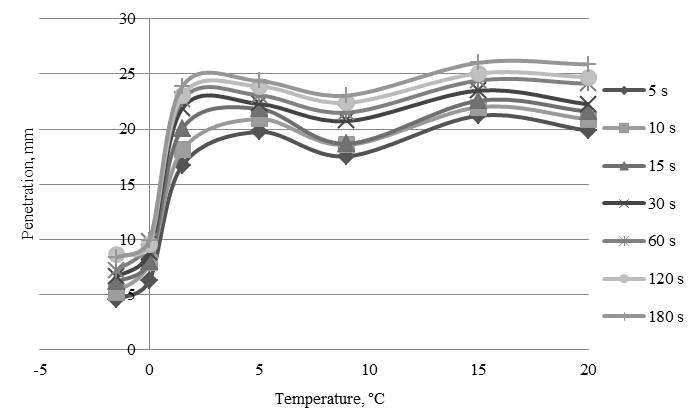

Fig. 1 show data on the change in the penetration depth depending on the time of immersion of the penetrometer cone (from 5 to 180 s) when the temperature of minced carp and silver carp changes from –1.5 to +20 °C.

Fig. 1. Penetration depth depending on the time of immersion of the penetrometer cone

with a change in the temperature of minced silver carp (a) and minced carp (b)

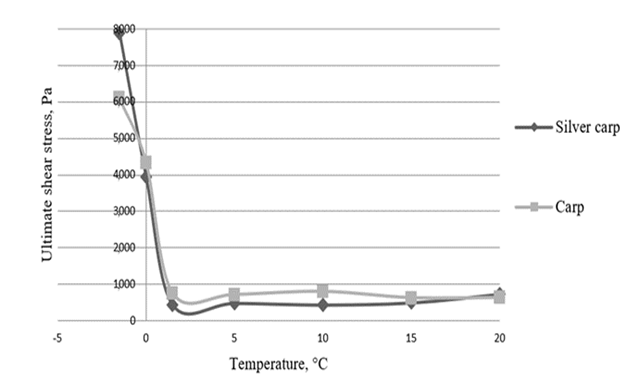

Fig. 2 shows experimental data on the change in the USS value with a change in the temperature of samples of minced carp and silver carp from –1.5 to +20 °C.

Fig. 2. Change in the USS value with a change in the temperature of minced carp and silver carp

It can be seen from Fig. 1, 2 that the greatest values of the penetration depth of the penetrometer cone, as well as the lowest USS values, belong to samples of minced carp and silver carp in the positive temperature zone from +2 °C and above. Lowering the temperature from +2 to –1.5 °C leads to significant changes in minced fish samples, while the USS values begin to increase sharply, and the penetration depth values sharply decrease.

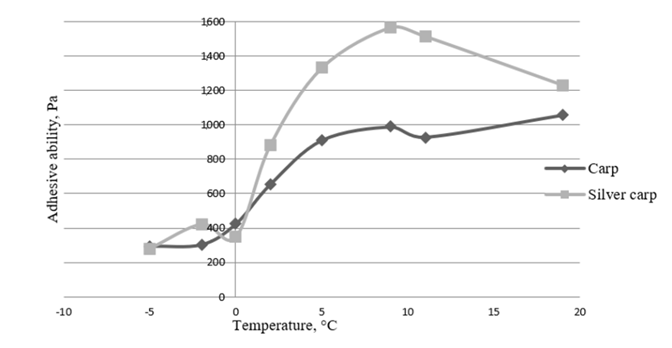

Fig. 3 shows the data on changes in the adhesive ability of samples of minced carp and silver carp when the temperature changes from –5 to +19 °C.

Fig. 3. Changes in the adhesive ability of samples of minced carp and silver carp depending on temperature changes

From the data presented in Fig. 3, it can be seen that the adhesive ability of samples of minced carp and silver carp increases with an increase in the temperature from –5 to +19 °C, and in the range from –2 to +4 °C, these changes are most pronounced.

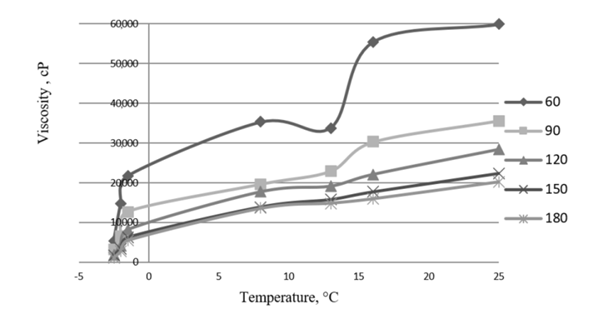

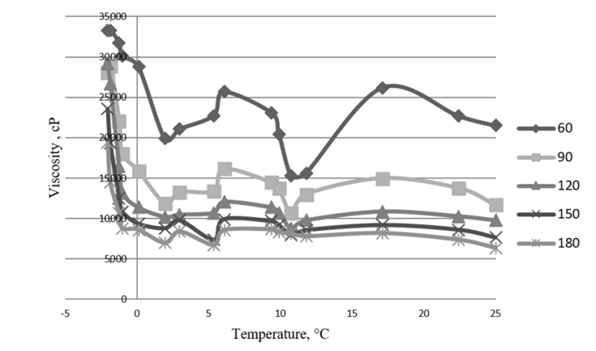

Fig. 4 show the experimental data on the change in viscosity (indicated in centipoise, cP) depending on the temperature change of minced carp and silver carp (from –2.5 to +25 °C) with a change in the spindle speed.

а

b

Fig. 4. Change in viscosity depending on the change in the temperature of minced silver carp (a), minced carp (b)

with a change in the number of spindle revolutions

Mathematical processing of experimental data hef (w) at t = +25 °C (Fig. 4) has made it possible to obtain the following dependence:

where: k – coefficient of proportionality depending on the type of fish; w – angular velocity of the viscometer spindle, s–1.

Explicitly:

– for minced carp:

– for minced silver carp:

Since the working body of a rotational viscometer selected for experimental studies does not allow obtaining the corresponding values of the shear rate gradient for its speed, it should be borne in mind that there is a certain proportional quantitative difference between Dependences (5), (6) and (7), (8) due to the relationship between the angular velocity of the spindle and the shear rate of minced fish. The qualitative nature of the compared dependences is identical.

The dynamics of changes in the rheological parameters of the studied types of minced fish, presented in Fig. 1-4, is obtained for the temperature range inherent in cold extrusion (without additional thermal exposure) and, in conjunction with the organoleptic observations performed on the ability of minced fish to form, allows us to evaluate it qualitatively and quantitatively. These data are also necessary to select and justify rational conditions for the extrusion process.

Discussion

Comparison of the absolute values of the obtained rheological indicators (Fig. 1-4) with the known reference data [8] shows that they differ (upward or downward, respectively). This is due to the fact that the studied samples of minced carp and silver carp are obtained with finer grinding of raw materials (less than 1 mm) and are characterized by uniformity and a structure close to homogeneous. At the same time, the characteristics of minced fish are confirmed in terms of chemical composition: The consistency of minced carp corresponds to smearing, and that of minced silver carp is characterized as high stable.

The rheological characteristics of minced fish characterize its ability to resist external forces during extrusion processing and depend on the structure and chemical composition of the product. We have obtained USS dependences of minced fish (salmon and hake) and poultry meat in a wide temperature range from –20 to +20 °C [13]. According to this indicator, a conclusion is drawn about the acceptability of the rational implementation of cold extrusion and co-extruding processes in the temperature range from –2 to 0 °C. This conclusion is also confirmed in another work [14], where it is indicated that at such temperatures mince formability is quite acceptable.

From Fig. 2 it can be seen that in the indicated temperature range (from –2 to 0 °C), which can be characterized as close to cryoscopic, the USS values for the studied aquaculture fish types are also maximum, which indicates, on the one hand, the stability of the product structure and, on the other hand, the need to apply a higher force to the product for its forming. For a comprehensive assessment of the rationality of these temperature parameters of the cold extrusion process, we also consider the influence of other rheological dependences that we obtained (Fig. 1-4).

The obtained experimental dependences of the effective viscosity on the temperature in the range from –2.5 to +25 °C at different shear rates (the number of revolutions of the viscometer spindle) for both types of minced fish have shown the following. In the range of positive temperatures, the effective viscosity of minced silver carp monotonously increases with increasing temperature, and the same value slightly decreases for minced carp. An exception is the temperature range from –2.5 to 0 °C. In this range, for both types of minced fish, its viscosity decreases sharply. The penetration depth values are also minimal (Fig. 1, b). On the contrary, the USS values sharply increase. In the specified range, the so-called “soft” ice is formed in the product, which gives a semi-solid consistency to the samples, bringing their properties closer to thick pastes [13]. This research, as well as studies conducted by O. V. Kosenko [14], confirm that under these temperature conditions, mince formability is quite acceptable, which allows us to conclude that it is expedient to perform cold extrusion and co-extruding processes.

An important rheological indicator of minced fish is its adhesive ability, which characterizes the degree of intermolecular interaction between the material and the contacting surface. The influence of the adhesive ability of minced fish in the forming process, which manifests itself in the form of harmful resistance, and the rational condition of the process is its minimization was studied by U. Buda et al. [15].

This conclusion is also confirmed by the experimental data shown in Fig. 3. In the considered temperature range the adhesive ability of minced fish is significantly less than at positive temperatures which is an important prerequisite for extrusion processing of the product in the flow cavities of the equipment.

As a research object U. Buda et al. [15] chose silver carpwhich due to its white color low market price, high-quality nutritious protein, and in the face of a reduction in the catch of marine fish and an increase in the volume of world aquaculture production, was recommended by the authors as a possible raw material for surimi-based products. Thus the process of extruding minced aquaculture fish (carp and silver carp), obtained by grinding on a cutter without adding various kinds of technological additives, is advisable to perform by the method of cold extrusion and co-extrusion. In the production of a co-extruded product, minced fish is recommended to be used as the casing of a combined product due to its rheological characteristics and ability to form. Rational temperature conditions for the process of cold extrusion should be considered the temperature range from –2.5 to 0 °C. This temperature range corresponds to the numerical values of the rheological parameters of minced carp and silver carp, indicated in Fig. 1-4 (within ±10%), which can be used to control the quality indicators of raw materials.

Further research may be related to the identification of the influence of technological additives (e. g., fillers, structure formers, stabilizers) on providing the best conditions for the formation of a product from minced fish and maintaining the shape of the finished product. At the same time, it is necessary to achieve a reduction in the smell of fish and the absence of oxidative processes and, which is of significant practical importance, to create new innovative products with functional ingredients, which is consistent with the materials of other works [6, 10].

Conducted theoretical and experimental studies of the influence of rheological characteristics of minced aquaculture fish (carp and silver carp) have shown the feasibility and prospects of its use to obtain new innovative products by cold extrusion and, especially, co-extrusion. Rational conditions for implementing these processes in a certain temperature range and the corresponding rheological characteristics of minced fish (carp and silver carp) have been determined. The above materials contribute to a wider involvement of aquaculture fish in the food market and the expansion of the range of new innovative products with the possibility of giving them functional properties. Based on the results of the work, the following conclusions can be drawn.

First, dependences of rheological characteristics (ultimate shear stress, penetration depth, effective viscosity, and adhesive ability) of minced aquaculture fish (carp and silver carp) in a temperature range (from –2.5 to +25 °C) have been identified for the first time.

Second, based on the rheological indicators and ability to form, as well as taking into account the moisture content in minced fish (W > 30%), the feasibility has been justified of using aquaculture objects of carp and silver carp to obtain products by cold extrusion and co-extrusion.

Third, rational conditions for the implementation of cold extrusion processes have been established, corresponding to the temperature range of –2.5 to 0 °C at which the rheological parameters of minced fish from carp and silver carp are acceptable for extrusion (adhesiveness lies in the range from 0.2 to 0.4 kPa; yield value is in the range from 5 to 8 kPa).

1. Offiah V., Kontogiorgas V., Falade K. O. Extrusion processing of raw food materials and by-products: a review // Critical Reviews in Food Science and Nutrition. 2019. V. 59 (18). P. 2979-2998. DOI:https://doi.org/10.1080/10408398.2018.1480007.

2. Остриков А. Н., Абрамов О. В., Рудометкин А. С. Экструзия в пищевой технологии. СПб.: Изд-во ГИОРД, 2004. 288 с.

3. Mohammed Shafig Alam, Raouf Aslam. Extrusion for the Production of Functional Foods and Ingredients // Innovative Food Processing Technologies. A Comprehensive Review. 2021. V. 22-35. DOI:https://doi.org/10.1016/b978-0-08-100596-5.23041-2.

4. Pagarkar A., Basu S., Mitra A., Joshi V. Novel Technology for Development of Value Added Fish Products. URL: https://www.researchgate.net/publication/316967799_Extruder-A_novel_technology_for_development_of_value_added_fish_products (дата обращения: 12.06.2023).

5. Silaws M., Dmitrijewa O. Fish processing industry modernization and co-extrusion method in fish product assortment diversification // Proceedings of the 2018 International Conference “Economic science for rural development”. 2018. N. 47. P. 305-311.

6. Surasani V. Application of Food Extrusion Process to Develop Fish Meat-Based Extruded Products // Food Engineering Reviews. 2016. V. 8 (2). P. 448-456.

7. Малкин А. Я., Исаев А. И. Реология: концепция, методы, приложения. СПб.: Профессия, 2007. 560 с.

8. Косой В. Д., Виноградов Я. И., Малышев А. Д. Инженерная реология биотехнологических сред. СПб.: Изд-во ГИОРД, 2005. 644 с.

9. Фатыхов Ю. А., Шуманов В. А., Зарудный В. А. Математическая модель процесса коэкструдирования пищевых масс // Вестн. Воронеж. гос. ун-та инженер. технологий. 2013. № 3. С. 41-43.

10. Choudhury G., Gogoi B., Oswalt A. Twin Screw Extrision of Pink Salmon Muscle and Rice Flour Blends: Effects of Kneading Elements // Journal of Aquatic Food Product Technology. 1998. V. 7 (2). P. 69-91.

11. ГОСТ 17660-97. Рыба специальной разделки мороженая. Технические условия. М.: Стандартинформ, 2010. С. 86-94.

12. ГОСТ 7636-85. Рыба, морские млекопитающие, морские беспозвоночные и продукты их переработки. Методы анализа. М.: Стандартинформ, 2010. С. 38-123.

13. Терещенко В. П., Альшевский Д. Л., Альшевская М. Н., Керевичене Е. Е. Изменение реологических характеристик фаршей из рыбы и птицы для производства коэкструзионных полуфабрикатов // Изв. Калининград. гос. техн. ун-та. 2009. № 15. С. 87-91.

14. Косенко О. В., Вакуленко Н. В., Слабая Е. А., Осинкин П. С. Разработка технологии мороженого фарша // Достижения и проблемы современных тенденций переработки сельскохозяйственного сырья: технологии, оборудование, экономика: сб. материалов Междунар. науч.-практ. конф. Краснодар: Экоинвест, 2016. С. 288-292.

15. Uma Buda, Bhargavi Priyadarshini, Majumdar R. K., Mahanand S. S., Patel A. B., Menta N. K. Quality characteristics of fortified silver carp surimi with soluble dictary fiber: Effect of apple pectin and konjac glucomannan // International Jornal of Biological Macromolecules. 2021. V. 175. P. 123-130.