Россия

Калининградская область, Россия

Представлены результаты комплексного исследования структурно-механических свойств фаршевых смесей из кальмара с наполнителями из ферментированной кожицы кальмара и фарша кальмара. Основное внимание уделено изучению их влияния на реологические характеристики и технологические показатели качества фаршевых систем. Объектами исследования выступили фарш кальмара командорского (Berryteuthis magister) и два вида наполнителей. Первый наполнитель получен путем предварительной ферментации кожицы кальмара, второй – с использованием однородного фарша кальмара. В обоих случаях наполнители изготавливались с использованием комплексной пищевой добавки КФ Стабипро ФЭТ. Исследовали образцы с разным соотношением фарша кальмара и наполнителей: 75 : 25, 50 : 50 и 25 : 75. Были установлены закономерности изменения эффективной вязкости, глубины пенетрации, предельного напряжения сдвига и адгезии в зависимости от состава фаршевых смесей. Особое внимание уделено взаимосвязи между реологическими характеристиками и технологическими показателями, такими как формуемость и формоустойчивость. Полученные данные позволили определить необходимое соотношение компонентов для обеспечения требуемых показателей качества полуфабрикатов. Выявлено существенное влияние используемых наполнителей на структурообразование в фаршевых системах. Показано, что оба типа наполнителей способствуют формированию более устойчивой структуры по сравнению с контрольными образцами чистого фарша кальмара. Практическая значимость работы заключается в обосновании выбора оптимальных рецептурных компонентов и их соотношений для производства формованных изделий из фарша кальмара. Результаты исследования могут быть использованы при разработке новых видов продукции и совершенствовании существующих технологий переработки кальмара.

кальмар, гидролизат кожицы кальмара, фарш, комплексная пищевая добавка, структурированный наполнитель, реологические свойства

Introduction

Fish products play a key role in ensuring Russia's food security by providing the population with high-quality proteins. However, rising prices for raw materials and finished products negatively affect consumption levels [1]. The majority of products obtained from aquatic biological resources are characterized by a low degree of processing [1]. Therefore, modernization of technological processes – including the efficient utilization of processing by‑products – is an urgent task aimed at introducing zero-waste technologies, expanding the product range and minimizing losses [2].

Current trends in the food industry show a steady increase in demand for products that are easy to prepare and combine excellent taste with reduced caloric value. Improving deep-processing technologies for aquatic bio-resources so as to obtain foods that are as ready-to-eat as possible has become relevant. Producing molded semi-finished products from hydrobionts is a promising direction for meeting growing consumer demand. Compared with other fish products, molded items are economically attractive for manufacturers. The technologies also allow for the efficient use of secondary resources generated during the cutting of aquatic organisms, which often remain under-utilized.

Cephalopods – in particular squids-belong to the category of delicacy and dietetic seafoods. Their unique biological traits determine their commercial value. Their ability to form dense aggregations, short life cycle and rapid growth ensure efficient harvesting. At the same time, squids possess excellent organoleptic qualities, high nutritional value and a significant edible-flesh yield of up to 80% [3].

Researchers from AtlantNIRO, such as M. P. Andreev, L. I. Perova, A. B. Odintsov, M. L. Vinokur and others, have made significant contributions to the study of commercial squid species and their size-weight and technological characteristics [4].

The expansion of molded squid-mince products is facilitated by the possibility of using specimens with mechanical damage as well as their tentacles and other edible parts, making the technological process low-waste and economically viable.

At present, the squid mantle – skinned or unskinned (37-56% of the total mass after cutting) – is widely utilized in industry and retail, whereas other parts (tentacles with skin; tentacles with skin and head, accounting for 20.7-24.3% of the catch weight) are used only to a limited extent or are completely discarded (liver 3.7-5.9%, gonads up to 2.5%, skin 1.3-6.4%) [5].

Rational use of under-utilized squid parts and the formation of the required rheological properties, structure and shape of the raw material during the production of semi-finished products remain topical issues in food technology.

Various methods are employed to achieve the desired rheological properties of products, including the use of structure-forming agents [6-9]. The most widely used are structure‑formers containing sodium alginate, such as the complex food additive KF Stabipro FET [10] and the multifunctional additive MITPRO 750 [11-17]. Their popularity is due to their ease of use, the rapid achievement of the required consistency parameters and the significant savings of raw materials they provide.

Nevertheless, the structural-mechanical characteristics of a filler largely depend on the composition of the protein-fat fraction of the starting raw material. An important task of modern food production is to develop formulations of frozen squid semi-finished products that utilize various parts of the animal and to determine the optimal ratios between squid fractions and structuring additives, whose introduction ensures the moldability of the mince mixture [10].

The aim of this work is to investigate the effect of structured fillers, manufactured from squid skin or mantle mince, on the structural and rheological characteristics of the mince mixture.

To achieve this aim, the following tasks were set:

– to study the influence of changing the mass fraction of structured fillers based on squid skin or mantle mince in mince mixtures on the structural‑mechanical properties of the resulting semifinished products;

– to determine acceptable ratios of structured fillers and raw squid mince that provide optimal dimensionnal stability and moldability of the produced mince mixtures.

Objects and methods of research

The objects of the study were mince from Commander squid (Berryteuthis magister) with structured fillers prepared from fermented squid skin or squid mantle mince, together with the complex food additive KF Stabipro FET (containing sodium alginate E401, calcium sulfate E516 and pyrophosphates E450iii). All raw materials, reagents and samples obtained during the experiment complied with regulatory safety requirements (TR CU 021/2011, TR CU 029/2012, TR EAEU 040/2016).

To prepare the mince, squid bodies were thawed and skinned. The cleaned mantles were ground in a meat grinder with a plate hole diameter of 3 mm.

To prepare the structured filler K1 based on squid

skin, the skin was preground and hydrolyzed with an acid-protease complex (enzyme preparation Enzy-Mix U) at a dosage of 0.1% of the raw-material mass. Hydrolysis was carried out for 2.5 h at 40 ± 2 °C. The enzyme was then inactivated at 70 ± 2 °C for 15 min. The fermented skin, cooled to 12 ± 2 °C (23.75% of the filler mass), was ground and mixed with water (71.25%) and KF Stabipro FET (5%) to homogeneity.

The structured filler K2 from squid mince was produced from ground mantle (19%), KF Stabipro FET (5%) and water (76%).

The resulting fillers were ground in a meat grinder with a 3 mm plate and incorporated into squid mince at levels of 25, 50 and 75%. Control samples were squid mince (K0) and the structured fillers from fermented squid skin (K1) and squid mince (K2).

Fig. 1 and 2 show molded samples of the mince mixture with different ratios of squid mince and structured fillers (K1 and K2).

|

|

|

|

|

|

|

а |

b |

c |

d |

e |

Fig. 1. Samples of minced meat mixture with different ratios of squid mince and structured filler (K2):

a – squid mince; b – 75 : 25; c – 50 : 50; d – 25 : 75; e – structured filler based on raw squid mince

|

|

|

|

|

|

а |

b |

c |

d |

Fig. 2. Samples of minced meat mixture with different ratios of squid mince and structured filler (K1):

a – 75 : 25; b – 50 : 50; c – 25 : 75; d – structured filler from fermented squid skin

The structural‑mechanical properties of the samples obtained and their ability to be molded were evaluated by indicators of moldability and dimensional stability.

Dimensional stability was determined on molded semi‑finished products (mass 50 ± 1 g) after a 5-minute holding at 7 ± 2 °C as the ratio of vertical diameter (Dv) to horizontal diameter (Dg), expressed as a percentage.

Descriptive characteristics and numerical values of dimensional stability (%) are presented in Table 1.

Table 1

Values of the dimensional stability index of molded semi-finished products from squid mince

|

Descriptive characteristics |

Dimensional |

|

The consistency of the mince is loose, dry, crumbly, the product after molding is easily destroyed, turning into pieces of irregular shape |

0 (not stable) |

|

The consistency of the mince is jelly-like. The mince is sticky to the touch, spreadable. When molding, the product sticks significantly, does not hold its shape, and spreads |

35 and less |

|

The consistency of the mince is quite elastic. The mince is not well formed, it sticks significantly, the product changes shape after forming |

35-80 |

|

The consistency of the mince is elastic, resilient. The mince does not stick, does not crumble, is perfectly formed, the product holds its shape perfectly |

80 and more |

To evaluate moldability, an organoleptic method based on the developed 5-point scale (Table 2) was used.

Table 2

Scoring scale for organoleptic assessment of squid mince moldability prepared

on the basis of structured fillers and raw squid mince

|

Moldability, scale descriptive characteristics |

Scale |

|

The mince is dense, hard, and cannot be molded or reshaped |

0 |

|

The consistency of the mince is jelly-like. The mince is sticky to the touch, spreadable. When molding, the product sticks significantly, does not hold its shape, and spreads The consistency of the mince is loose, dry, crumbly, the product after molding easily collapses, turning into irregularly shaped pieces |

1 |

|

The consistency of the mince is jelly-like. When molded, the mince sticks, the product does not hold its shape well, and spreads over a short period of time The consistency of the mince is crumbly. Touching the product with slight force after molding |

2 |

|

The consistency of the mince is sufficiently elastic. The mince is not molded well enough, it sticks The consistency of the mince is not elastic enough. The mince can be molded, but the product does not hold its shape during further technological operations |

3 |

|

The consistency of the mince is elastic, springy. The mince is well formed, but slightly sticks, the product holds its shape The consistency of the mince is elastic, springy. The mince is well formed, the product holds its shape, but slightly crumbles |

4 |

|

The consistency of the mince is elastic, resilient. The mince does not stick, does not crumble, is perfectly formed, the product holds its shape perfectly |

5 |

In studying the structural-mechanical properties of the samples, the following indicators were determined: penetration depth, ultimate shear stress (USS), effective viscosity and adhesion.

Penetration depth and USS were measured on a KP‑3 cone plastometer.

Adhesion of the mince was determined on a laboratory setup for measuring stickiness (adhesion). The principle is to measure the force required to detach a plate uniformly from the product over the entire contact area. When determining the adhesive capacity, before measurement, the mince sample was placed between two stainless-steel plates (surface area 4.84 cm²) and pre-pressed with a 1 kg load for 5 s.

Effective viscosity was measured on a Brookfield DV-II + Pro rotational viscometer in accordance with the instrument manual (Rheocalc v.3.3 build 49‑1) using spindle RV7 made of stainless steel, cylindrical shape. All studies were performed in triplicate. The results were statistically processed using Microsoft Office 2016.

Results of the study

Squid muscle contains up to 60% sarcoplasmic proteins and only up to 30% myofibrillar proteins. Consequently, squid muscle tissue, originally dense, becomes fluid after grinding [18, 19]. The addition of structured fillers made from under-utilized squid parts together with KF Stabipro FET makes it possible to obtain a mince mixture with the required structural-mechanical properties for producing molded products.

One of the main characteristics of mince systems is the dependence of effective viscosity on shear rate. Effective viscosity reflects the equilibrium between structural recovery and breakdown.

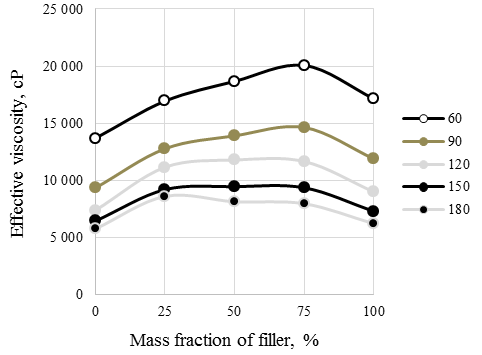

Fig. 3 shows the changes in effective viscosity, cP, of squid mince mixtures with various structured fillers as a function of spindle rotation speed.

|

а |

b |

Fig. 3. Changes in the effective viscosity of the minced meat mixture depending

on the content of structured filler and the spindle speed: a – from fermented squid skin; b – from squid mince

The data in Fig. 3 demonstrate that control samples without structured fillers have the lowest effective viscosity, indicating an unstable, fluid consistency. Structured fillers from squid mince and fermented squid skin impart a dense, elastic consistency, as evidenced by higher viscosity values.

Shear properties-whose principal indicator is the ultimate shear stress – are crucial for characterizing the rheology of mince products. USS values are used to calculate, predict and optimize technological processes, as well as to monitor and standardize product consistency.

The effect of structured fillers and their mass fraction on penetration depth, mm, and USS is illustrated in Fig. 4, 5.

|

|

|

|

а |

b |

Fig. 4. The depth of immersion of the penetrometer cone h in the minced meat mixture depending

on the time τ and content of structured filler in it, %: a – from fermented squid skin; b – from squid mince

Fig. 5. Change in the value of the minced meat mixture USS ϴ depending on the content

of structured filler made from fermented squid skin (K1) and homogeneous minced squid (K2)

Fig. 4 and 5 show that control squid mince (K0) exhibits maximum penetration depth and low USS, indicating a fluid, unstable consistency. Adding structured fillers decreases penetration depth and increases USS, indicating a stronger, more cohesive structure. Optimal penetration depth occurs at a 50 : 50 mince-to-filler ratio, where the mixture retains sufficient plasticity while displaying improved moldability and dimensional stability.

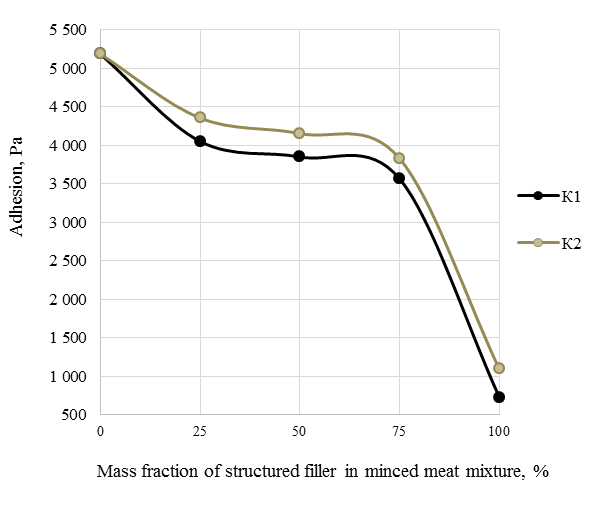

Adhesion is an important rheological parameter of food materials, characterizing the extent to which a product sticks to contact surfaces during processing.

Fig. 6 presents the changes in adhesion, Pa, of the mince mixture with different structured fillers and minced squid.

Fig. 6. Change in the adhesive capacity of the minced meat mixture depending on its content (in %)

of structured filler made from fermented squid skin (К1) and homogeneous squid mince (К2)

Control squid mince without structured fillers shows the highest adhesion and is therefore highly sticky. Structured filler samples have the lowest adhesion and a dry, loose consistency. Adding 25-75% structured fillers based on squid mince or fermented skin reduces mince adhesion by an average of 25%, which is beneficial because high adhesion leads to raw‑material losses during processing when it comes into contact with technological equipment. Reduced adhesion correlates with improved organoleptic characteristics – less stickiness, greater homogeneity and plasticity. Dimensional stability was used as an objective measure of the molded product's ability to retain shape before thermal or cold treatment. The influence of the mass fraction of structured fillers on the dimensional stability and moldability of squid mince is shown in Table 3.

Table 3

Data on changes in the indices of dimensional stability and moldability of molded semi-finished products

based on various structured fillers and squid mince

|

Indicator |

Sample / mass fraction of filler in the mixture, % |

||||||||

|

К0* |

1** |

2 |

1 |

2 |

1 |

2 |

К1 |

К2 |

|

|

25 |

25 |

50 |

50 |

75 |

75 |

||||

|

Dimentional stability, % |

33.4 ± 1.1 |

64.1 ± 2.1 |

61.7 ± 2.0 |

82.4 ± 2.7 |

81.1 ± 2.7 |

78.1 ± 2.6 |

76.5 ± 2.5 |

0 |

|

|

Moldability, scale |

1.3 ± 0.1 |

3.4 ± 0.1 |

3.3 ± 0.1 |

4.9 ± 0.1 |

4.9 ± 0.1 |

3.9 ± 0.1 |

3.8 ± 0.1 |

1.1 ± 0.1 |

1.1 ± 0.1 |

* К0 – minced squid; К1 – structured filling made from fermented squid skin; К2 – structured squid mince filling; ** 1 – samples of squid mince with structured filling made from fermented squid skin; 2 – samples of squid mince with structured squid mince filling.

As shown by Table 3 and Fig. 5, raw squid mince without structured fillers has a jelly-like consistency, is excessively sticky and smears readily. During molding, the product sticks to the working surface, does not retain its shape and flows. Molded samples consisting solely of structured fillers (without squid mince) have a loose, dry consistency; the product formed from them crumbles and is easily destroyed, disintegrating into individual granules consisting of crushed structured filler. Samples containing 25 or 75% structured filler show satisfactory moldability and dimensional stability. However, the minced meat mixture with the addition of 25% structured fillers sticks significantly, the molded product does not hold its shape well, which will lead to deformation of the products during further technological operations. Minced meat with the addition of 75% structured filler has a loose consistency, but is molded quite well, however, such an amount of structured filler in the minced meat mixture can negatively affect the organoleptic properties of the finished molded products made from it. Mince mixtures made from squid mince and fermented squid skin in a 50 : 50 ratio have an elastic, resilient consistency, do not stick or crumble, and molded semi-finished products retain their shape perfectly.

Conclusion

The influence of structured fillers based on squid mince and fermented squid skin on the structural mechanical properties of mince mixtures for molded semi-finished products was investigated. The optimal ratio of structured filler to raw squid mince was found to be 50 : 50, irrespective of filler type. This mixture exhibits excellent moldability (5 points) and a dimensional stability index of about 80%, confirming its suitability for producing molded semi-finished products. The use of squid-skin-based structured filler is promising for rational raw-material utilization within the framework of zero-waste technologies.

1. Салтыков М. А., Фисенко А. И. Рыбохозяйственный комплекс России: нарративный анализ тенденций и стратегические задачи развития производства и потребления продукции // Вестн. Астрахан. гос. техн. ун-та. Сер.: Экономика. 2023. № 3. С. 69–81.

2. Об утверждении Стратегии развития машиностроения для пищевой и перерабатывающей промышленности РФ на период до 2030 г.: Распоряжение Правительства РФ от 30 августа 2019 г. № 1931-р. URL: government.ru/docs/all/123583/ (дата обращения: 12.03.2025).

3. Романова А. И., Ивченкова Е. Н., Альшевский Д. Л., Шендерюк В. И. Формованные полуфабрикаты из фарша кальмара // Вестн. Астрахан. гос. техн. ун-та. Сер.: Рыбное хозяйство. 2012. № 2. С. 164–170.

4. Перова Л. И., Винокур М. Л., Андреев М. П. Технологическая характеристика гигантского кальмара дозидикуса (Dosidicus gigas) и его рациональное использование // Вестн. Астрахан. гос. техн. ун-та. Сер.: Рыбное хозяйство. 2012. № 2. С. 164–170.

5. Купина Н. М. Сезонные изменения размерно-массового состава тихоокеанского кальмара Todarodes pasificus // Изв. ТИНРО. 2008. Т. 153. С. 399–403.

6. Андреев М. П., Морозов И. О. Влияние структурообразователей различной природы на реологические свойства желейных пищевых продуктов на основе вторичного рыбного сырья // Изв. Калинингр. гос. техн. ун-та. 2020. № 57. С. 89–98.

7. Богданов В. Д., Симдянкин А. А., Панкина А. В., Мостовой В. Д. Исследование влияния структурорегулирующих добавок на свойства рыбных фаршевых систем // Вестн. Мурм. гос. техн. ун-та. 2022. Т. 25. № 3. С. 219–230.

8. Parmar V., Sharma R., Sharma S., Singh B. Recent advances in fabrication of food grade oleogels: structuring methods, functional properties and technical feasibility in food products // Journal of Food Measurement and Characterization. 2022. V. 16. Р. 4687–4702.

9. Kumar A., Hanjabam M. D., Kishore1 P., Uchoi D., Panda S. K., Mohan C. O., Chatterjee N. S., Zynudheen A. A., Ravishankar C. N. Exploitation of Seaweed Functionality for the Development of Food Products // Food and Bioprocess Technology. 2023. V. 16. P. 1873–1903.

10. Альшевский Д. Л., Мавлюдов Р. С., Альшевская М. Н. Научное обоснование рецептуры и технологических параметров структурированного наполнителя, приготовленного из недоиспользуемых фракций кальмара // Вестн. Камч. гос. техн. ун-та. 2024. № 69. С. 8–20.

11. Наумов В. А., Коржавина Ю. Н., Шибеко А. Г., Сингаев В. И., Альшевский Д. Л. Регрессионная модель плотности имитационного шпика // Изв. Калинингр. гос. техн. ун-та. 2020. № 58. С. 94–102.

12. Korzhavina Yu. N., Alshevsky D. L., Ustich V. I., Kazimirchenko O. V., Alshevskaya M. N. Scientific substantiation of the use of imitation fat in the production of semifinished fish products // Vestnik of Astrakhan State Technical University. Series: Fishing industry. 2022. N. 3. P. 66–73.

13. Альшевский Д. Л., Аюпова Т. М. Разработка рецептуры имитационного шпика на основе жиросодержащих компонентов конины // Науч.-практ. журн. «Технология и товароведение инновационных пищевых продуктов» ОГУ им. И. С. Тургенева. 2023. № 6 (83). С. 8–12.

14. Alshevskiy D., Korzhavina Yu., Alshevskaya M., Ustich V. Application of fatcontaining edible fish waste for making imitation lard // AIP Conf. Proc. 2022. V. 2636 (1). P. 020015. https://doi.org/10.1063/5.0103970.

15. Шодиев Д. А., Нажмитдинова Г. К. Пищевые добавки и их значение // Universum: технические науки: электрон. научн. журн. 2021. V. 10 (91). URL: https://7universum.com/ru/tech/archive/item/12344 (дата обращения: 12.03.2025).

16. Шодиев Д. А., Курбонов Х. А. Перспективы использования пищевых добавок в пищевой промышленности // Universum: технические науки: электрон. науч. журн. 2022. V. 5 (98). URL: https://7universum.com/ru/tech/archive/item/13734 (дата обращения: 12.03.2025).

17. Штенина Д. В. Обзор функционально-технологических добавок, применяемых при производстве формованных изделий из гидробионтов // Вестн. науки и образования. 2022. № 1 (121). Ч. 2. С. 34–37.

18. Мезенова О. Я. Способ определения взаимосвязи органолептической оценки качества и сдвиговых характеристик тканей рыбных продуктов // Совершенствование технологии и контроля производства продукции из рыбного сырья: сб. науч. тр. / отв. ред. Терещенко В. П. и др. Калининград: Изд-во КТИРПиХ, 1990. С. 118–128.

19. Prüfshema für Räucherflach – Vorgeschnittene Erzeugnisse // Deutshe Landwirshafts – Gesellschaft e.V. (DLG), Eschborner Landstr. 122, D 99 Frankfurt am Main, 1995. P. 56–68.