Russian Federation

Russian Federation

Russian Federation

A study was conducted in order to reduce harmful emissions of marine diesel by feeding additional components into the cylinder due to stricter requirements for the level of harmful emissions from marine power plants. It is noted that it is most difficult to achieve compliance with environmental requirements for diesel engines that have been built for more than 20 years and have been operated on ships for a long time. The use of complex methods to improve their environmental characteristics can lead to a significant increase in the cost of measures to modernize them and increase operating costs. The supply of additional components to diesel cylinders to reduce harmful NOx and COx emissions is considered. The experiments were carried out on a marine diesel generator based on diesel 1H17.5/24 with the use of water and ethanol supply to the cylinder. As a result of high-pressure water supply, a 30% reduction in NOx was noted, and no reduction in COx was noted. When ethanol is supplied, it is revealed that there is a positive effect on the reduction of NOx, but there is an increase in CO and exhaust gas temperature, which does not make it possible to unambiguously determine the positive effect. Additional research is required on the use of ethanol and other components as additional components to improve the environmental performance (reduce emissions) of marine diesel engines. Conclusions are drawn about the possibility of using alcohol solutions, changing the amount and time of supply of ethanol and other additional components to obtain more effective indicators.

ecology, reduction of harmful emissions, marine diesel, additional components, marine power plants

Introduction

The negative impact of industry and transport on the environment is currently one of the key problems that humanity has faced. Toxic substances in the exhaust gases of internal combustion transport engines lead to the greenhouse effect, acid rain, poisoning of the biosphere and other consequences, thus, emissions are divided into: greenhouse and harmful. Marine internal combustion engines can have a large capacity and, accordingly, the amount of harmful substances that are released into the atmosphere during their operation can be very significant, which leads to a deterioration of the environmental situation in places of intensive shipping and ports. The control of the level of harmful substances in the exhaust gases of marine diesel engines is carried out by the International Maritime Organization (IMO), which has developed regulatory documents in this area, for example, the International Convention MARPOL 73/78 with annexes (hereinafter - MARPOL) [1, 2] and periodically reviews the established standards in the direction of tightening. Thus, separate zones for the control of harmful NOx and SOx emissions (NECA and SECA, respectively) are already being allocated in the world ocean, and emission standards in other zones of the world ocean have been significantly tightened. The achievement of the standards established by MARPOL is currently possible with the help of several methods – improving the design of marine diesel engines; cleaning exhaust gases; feeding additional components into the cylinders; using alternative fuels and others. Each of the methods has its advantages and disadvantages and can be used both in the manufacture of new diesel engines and in the operation of existing ones. The presence of diesel engines on a large number of ships that have been in operation for a long time leads to the need to search for technical solutions that do not lead to a significant change in the design of diesel engines and its systems, but are aimed at improving the combustion process of the fuel-air mixture in the cylinders. One of such solutions is the supply of water, ethanol, rapeseed oil, up to the supply of binary fuels to diesel cylinders and thus the effect on the formation of harmful substances – SOx, NOx, COx and others. Such methods were considered in their research by a fairly large number of specialists, such as: V. A. Likhanov [3], V. A. Markov [4, 5], K. Weiser [6], Yu. Zh. Saade [7], A. S. Kuleshov [8], A. R. Kulchitsky [9] and others. However, most of the research concerns motor vehicle diesels and does not reflect the specifics of the work of ship's main diesels powered by a propeller and ship's auxiliary diesels as part of diesel generators. Therefore, at the Astrakhan State Technical University (ASTU) at the Department of “Operation of Water Transport and Industrial Fishing” under the guidance of Doctor of Technical Sciences, Professor M. N. Pokusaev, both theoretical and practical research has been conducted for several years in the field of improving the environmental characteristics of marine engines.

Purpose of the study: to assess changes in the environmental characteristics (emissions) of a medium-speed marine diesel engine when additional components are supplied to the cylinder.

The following research methods were used: analysis and synthesis of scientific knowledge, physical experiment, processing of experimental results.

Research results

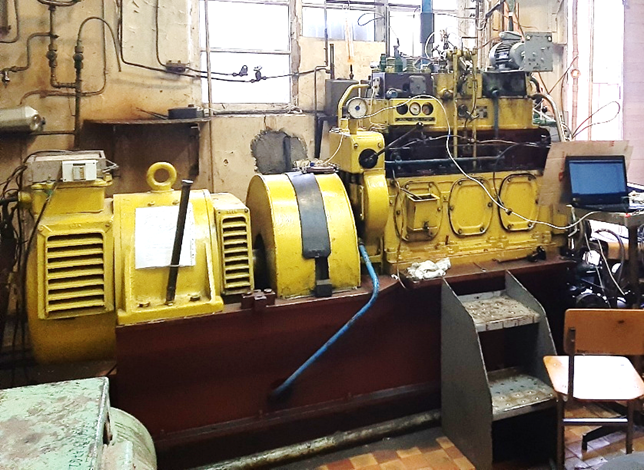

To conduct experimental studies, a stand with a diesel generator based on the ship's 3NVD24 medium-speed diesel engine (after modernization 1Ч17.5/24), which was available at ASTU and modernized with the participation of the authors, was used. During the period of widespread use of diesel engines of the Ч17,5/24 series, the 3NVD24 diesel was used as an auxiliary engine on fishing vessels to drive electric generators. The rated power of the upgraded single-cylinder diesel variant is 16 kW at a rotation speed of 630 min–1. The general view of the test bench is shown in Fig. 1. The stand was upgraded by installing a system for supplying additional components with an electronic control unit, equipped with the necessary instrumentation and recording equipment of high sensitivity.

Fig. 1. General view of the test bench for supplying additional components to the 1Ч17.5/24 diesel cylinder

The main element for the supply of additional components is the Hyundai 353102G710 nozzle with electronic control from a microcontroller (Fig. 2).

Fig. 2. Installed nozzle for supplying additional components to the 1Ч17.5/24 diesel cylinder

The injector has the following technical characteristics: full opening time – 5.5 degrees of crankshaft rotation (CR); flow rate at full opening – 60 l/h (at a pressure of 150 kg/cm2); type of liquid being sprayed – diesel fuel, ammonia, ethanol, water; supply voltage 12 V. To create high pressure when supplying components to the nozzle, the Karcher system was used with the following technical characteristics: operating pressure 150 kg/cm2; productivity – up to 600 l/h; maximum power consumption 3 000 W; the presence of a fine water filtration system.

The measuring system used was the author's design using pressure and temperature sensors based on an STM microcontroller. The measurement of harmful emissions was carried out with a Testo 350-MARITIME gas analyzer, included in the State Register of Measuring Instruments No. 49158-12.

The tests were carried out in one operating mode of the laboratory bench with a load of 50% of the rated power. The supply of additional components was carried out at top dead center (TDC). The angle of advance or retardation of the supply of additional components relative to TDC was not varied in this experiment and is the subject of further research. The results of the experiments are presented in Table 1 (O2 – oxygen content, %; CO – CO content, ppm; NO – NO content, ppm; NO2 – NO2 content, ppm; H2 – water vapor content, ppm; NOx – NOx content, ppm; Tg – exhaust gas temperature, °C; CO2 – CO2 content, %).

Table 1

Results of experiments on the supply of additional components

|

Type of additional |

Parameters of exhaust gases and air entering the cylinder |

|||||||

|

O2, % |

CO, ppm |

NO, ppm |

NO2, ppm |

H2, ppm |

NOx, ppm |

Тg, °C |

CO2, % |

|

|

When supplying water |

||||||||

|

Without additional components |

14.0 |

124.8 |

426.7 |

43.0 |

17.0 |

469.6 |

331.4 |

4.0 |

|

Water when supplied during 29° of CR |

14.0 |

120.0 |

341,7 |

43.7 |

17.7 |

385.4 |

328.6 |

4.0 |

|

Water when supplied during 54° of CR |

14.0 |

128.2 |

295.3 |

44.3 |

19.2 |

340.6 |

292.2 |

4.0 |

|

When supplying ethanol |

||||||||

|

Without additional components |

14.0 |

124.5 |

401.1 |

44.7 |

19.1 |

444.6 |

323.9 |

4.0 |

|

Ethanol (alcohol) when supplied during 29° of CR (at a supply pressure of 140 kg/cm2) |

12.5 |

282.0 |

269.5 |

77.1 |

26.1 |

346.6 |

397.0 |

4.9 |

|

Ethanol (alcohol) when supplied during 69° of CR (at a supply pressure of 75 kg/cm2) |

9.3 |

2 191.9 |

262.1 |

83.6 |

73.3 |

345.7 |

507.0 |

6.7 |

|

Ethanol (alcohol) when supplied during 72° of CR (at a supply pressure of 75 kg/cm2) |

7.3 |

2 855.7 |

282.0 |

38.1 |

633.9 |

320.0 |

603.2 |

7.8 |

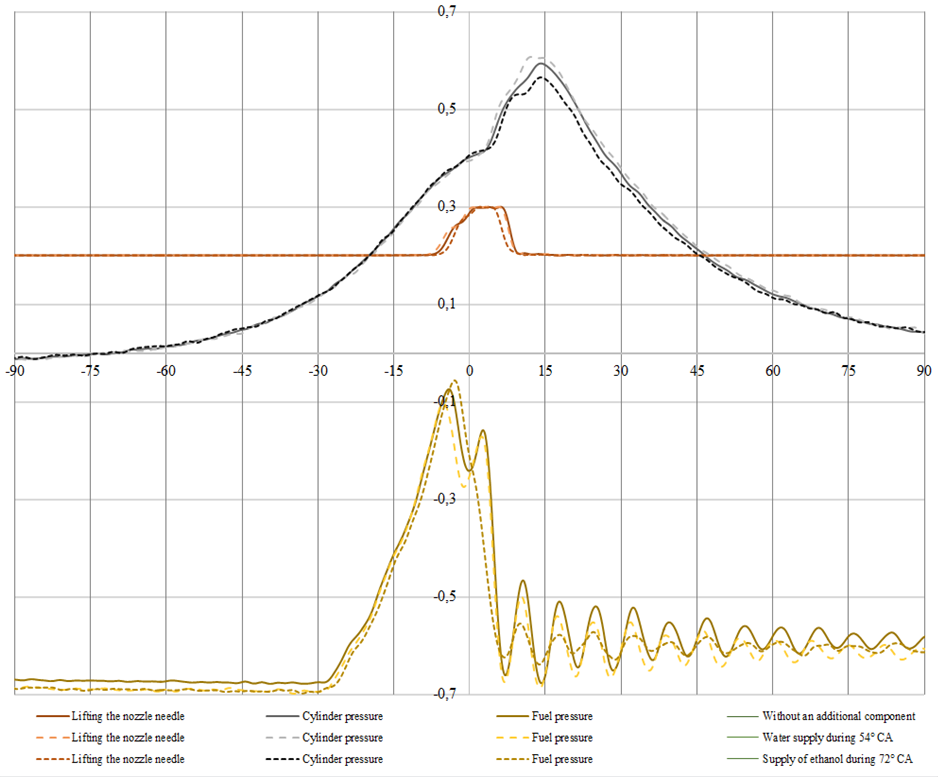

During the experiments, not only results for reducing harmful emissions were obtained, but also indicator diagrams (Fig. 3). The water supply period ranged from 0 (TDC) to 54 (CR), and the achieved injection pressure was up to 140 kg/cm2, the diesel crankshaft rotation speed remained practically unchanged and amounted to 603 min–1.

The ethanol supply period, in turn, ranged from 0 to 72° CR, the ethanol injection pressure was 75 kg/cm2, the crankshaft rotation speed was also 603 min–1.

Parameters of ethanol supply modes are given in Table 2.

Table 2

Parameters of ethanol supply modes

|

Mode No. |

Diesel CR speed, min–1 |

Duration of ethanol supply from TDC, degrees CR |

Injection pressure, kg/cm2 |

|

1 |

603 |

Without additional components |

Without additional components |

|

2 |

603 |

35 |

101 |

|

3 |

603 |

70 |

80 |

|

4 |

603 |

73 |

70 |

Fig. 3. Indicator diagrams of diesel engine 1Ч17.5/24 when operating without supply

of an additional component (pure diesel fuel), with water supply and ethanol supply

The diagrams were processed in the range from 200 to 4 000 diesel operating cycles. To increase the processing accuracy, the cross-correlation method was used (cross-correlation is a measure of the similarity of two series as a function of the offset of one relative to the other).

Discussion

The results of the experiments show that the supply of additional components affects the environmental characteristics of a marine diesel engine as follows.

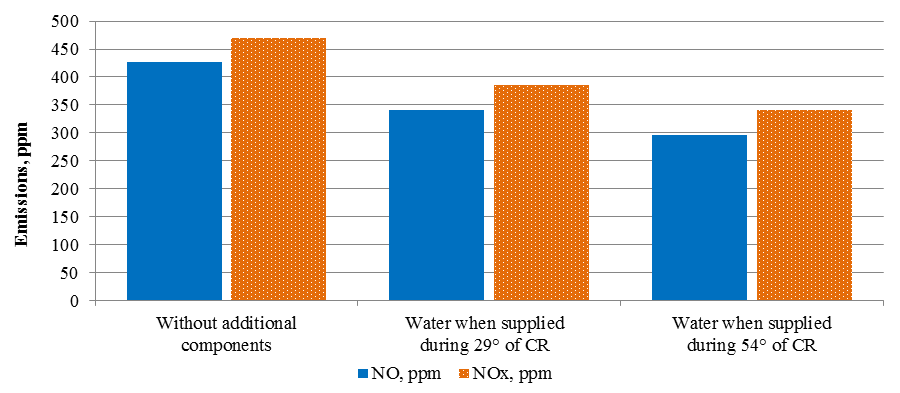

When water is supplied during 54° CR, it was possible to reduce NO emissions by 30.8%. The reduction in NOx when water was supplied during 29° CR was 18%, and when water was supplied during 54° CR, respectively, 27.5%. The results obtained are shown in Fig. 4. Thus, the most effective mode for reducing NO and NOx will be the water injection mode during 54° CR. There was practically no change in the CO level; its value in individual modes when water was supplied differed by no more than 3.8%, which can be attributed to experimental errors.

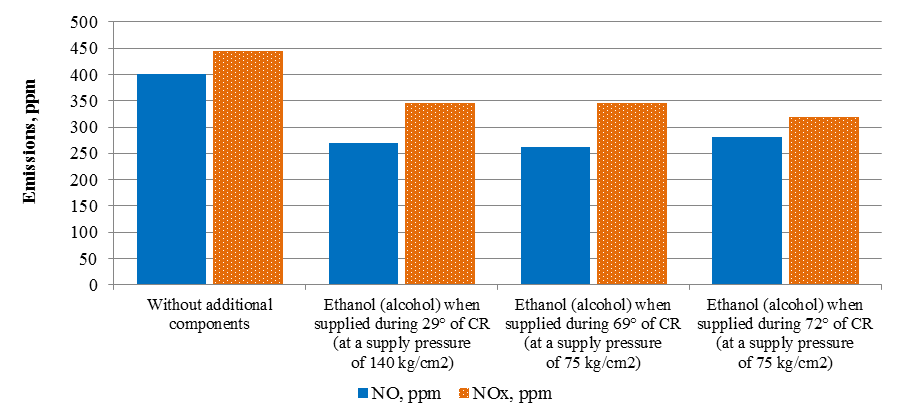

The supply of ethanol has led to an ambiguous effect on the environmental characteristics of the diesel engine - on the one hand, the injection of ethanol leads to a decrease in NO and NOx, and when supplied during 29° CR, it is possible to reduce NO by 32.8%, and NOx by 22%. However, no further sharp change in emissions is observed when the supply duration changes to 72° CR; the results are presented in Fig. 5.

Fig. 4. Change in NO and NOx when water is supplied

Fig. 5. Change in NO and NOx when ethanol is supplied

On the other hand, the supply of ethanol leads to a sharp increase in CO emissions – 2.3 times with a supply duration of 29° CR, and with an increase in the ethanol supply time to 72° CR, CO emissions become 23 times higher than in the absence of an additional component. One can also note a significant increase in the temperature of the exhaust gases – by 22.6% when supplied at 29° CR, and by 1.9 times when supplied at 72° CR. There is also an increase in the amount of water vapor by 36.7% with an ethanol supply duration of 29° CR and more than 33 times with a supply duration of 72° CR.

If we compare the results obtained with the studies of other specialists, then the positive effect on the environmental characteristics of internal combustion engines when supplying water is indicated in the work of V. A. Markov and A. S. Kuleshov [8]. In particular, it is noted that calculations in the Diesel-RK software package [10] for the D-245 diesel engine (4ЧН11/12.5) showed that when water is injected into the cylinders, a reduction in NOx emissions is expected from 3.05 g/(kW · h) (without water supply) to 2.012 g/(kW · h), that is, by 51.5%.

Analysis of the obtained indicator diagrams (Fig. 3) shows that when water is supplied, the intensity of the increase in pressure p after injection of fuel and water (TDC) with the achievement of the maximum value pz occurs in steps, which is caused by the evaporation of the volume of supplied water. When ethanol is injected, the nature of the indicator diagram (Fig. 4) gives a pronounced stepwise increase during the combustion of the main part of the ethanol after its evaporation. In addition, when ethanol is supplied, the pressure increases during the exhaust stroke, while the drop to atmospheric pressure occurs around 180° CR. For comparison, reaching the level of atmospheric pressure when supplying only diesel fuel occurs in the region of 150° CR. This undoubtedly affects the thermally stressed state of the diesel engine and gas exchange characteristics.

Conclusions

Based on the results of the study, the following conclusions can be drawn:

1. The supply of additional components in the form of water and ethanol gives positive results in increasing the environmental characteristics (reducing NOx emissions) of the 1Ч17.5/24 marine diesel engine.

2. Water supply leads to a decrease in NO, NOx emissions, but does not lead to a change in CO emissions. The most effective water supply mode for reducing emissions of NO (by 30.8%), NOx (by 27.5%), is a duration of 54° CR at an injection pressure of 137 kg/cm2. The results obtained correlate with the calculations of V. A. Markov and A. S. Kuleshov for diesel engine D-245 (4ЧН11/12.5), obtained by them in the Diesel-RK software package.

3. Ethanol injection has an effect on reducing NO, NOx emissions; the most effective environmental mode is its supply within 29° CR. However, the presence of an increase in CO by 2.3 times and exhaust gas temperature by 1.9 times, even with such a short-term supply, is a negative side effect for the use of ethanol as an additional component under the selected initial experimental conditions.

4. Analysis of indicator diagrams shows that when ethanol is supplied, pressure increases during the exhaust stroke, which is explained by the longer burnout of ethanol.

5. When conducting further research, it is necessary to consider supplying ethanol in a shorter time or using an alcohol solution of different concentrations to combine the effect obtained from supplying water and ethanol. It is also necessary to conduct experiments to change the angle of advance (delay) of the supply of additional components relative to TDC, since this also affects harmful engine emissions.

1. Pravila predotvrashcheniia zagriazneniia atmosfery s sudov: Prilozhenie VI (pere-smotrennoe) k Konventsii MARPOL 73/78 [Rules for the prevention of atmospheric pollution from ships: Annex VI (revised) to the MARPOL 73/78 Convention]. Saint-Petersburg, Izd-vo TsNIIMF, 2012. 87 p.

2. Rezoliutsiia MERS 251 (66): popravki k Prilozheniiu VI k Konventsii MARPOL, 2014 [Resolution MEPC 251 (66): Amendments to Annex VI to the MARPOL Convention]. Available at: https://base.garant.ru/74194387/53f89421bbdaf741eb2d1ecc4ddb4c33/?ysclid=lp0ud774ru487591645 (accessed: 01.06.2023).

3. Likhanov V. A., Kozlov A. N., Araslanov M. I. Vliianie primeneniia etanola i rapsovogo masla na pokazateli protsessa sgoraniia i sazhesoderzhaniia v tsilindre traktornogo dizelia 2Ch 10,5/12,0 v zavisimosti ot izmeneniia nagruzki [The effect of the use of ethanol and rapeseed oil on the combustion process and soot content in the cylinder of a tractor diesel 2H 10.5/12.0 depending on the load change]. Vestnik Chuvashskoi gosudarstvennoi sel'sko-khoziaistvennoi akademii, 2018, no. 1 (4), pp. 59-64.

4. Markov V. A., Kozlov S. I. Topliva i toplivopodacha mnogotoplivnykh i gazodizel'nykh dvigatelei [Fuel and fuel supply of multi-fuel and gas-diesel engines]. Moscow, Izd-vo MGTU, 2000. 296 p.

5. Markov V. A., Bashirov R. M., Gabitov I. I. Toksichnost' otrabotavshikh gazov dizelei [Toxicity of diesel exhaust gases]. Moscow, Izd-vo MGTU imeni N. E. Baumana, 2002. 376 p.

6. Weiser K., Ennemoser A. 3D-CFD modelirovanie sgoraniia i teploobmena v bystrokhodnom dizele [3D-CAD modeling of combustion and heat transfer in a high-speed diesel engine]. THIESEL Conference (Valensiia, Ispaniia 11-13 sentiabria 2002 g.). AVL List GmbH. Pp. 22-36. Available at: https://www.studmed.ru/weiser-k-ennemoser-a-3d-cfd-modelirovanie-sgoraniya-i-teploobmena-v-bystrohodnom-dizele_f3d6da77a99.html?ysclid=lp0uttgh4s978382546 (accessed: 01.06.2023).

7. Saade Iu. Zh. Razrabotka metoda organizatsii rabochego protsessa dizelia, ispol'zuiushchego n v kachestve dobavki k dizel'nomu toplivu, s tsel'iu povysheniia ekologicheskikh kachestv dvigatelia: avtoreferat dis. ... kand. tekhn. nauk [Development of a method for organizing the working process of a diesel engine using n as an additive to diesel fuel in order to improve the environmental qualities of the engine: abstract of the dissertation of the Candidate of Technical Sciences]. Moscow, 1992. 16 p.

8. Markov V. A., Kuleshov A. S. i dr. Raschetnye issledovaniia sposobov podachi vody v tsilindry dizel'nogo dvigatelia [Computational studies of methods of water supply to diesel engine cylinders]. Transport na al'ternativnom toplive, 2020, no. 4 (76), pp. 50-61.

9. Kul'chitskii A. R. Toksichnost' avtomobil'nykh i traktornykh dvigatelei [Toxicity of automobile and tractor engines]. Vladimir, Izd-vo VlGU, 2000. 256 p.

10. Programmnyi kompleks DIZEL''-RK [DIESEL-RK software package]. Available at: https://diesel-rk.com/Rus/index.php?page=Main (accessed: 08.09.2023).