Russian Federation

Russian Federation

Russian Federation

Russian Federation

Russian Federation

The world statistics of fleet accidents indicate that the most dangerous type of damage to engineering structures are fragile destructions that occur suddenly and spread at high speed. The causes of brittle fractures are defects such as corrosion-fatigue cracks, which often occur due to active corrosion processes. Seawater contains a large number of microorganisms that contribute to the acceleration of corrosion and fouling of metal structures in contact with water. The main method of corrosion protection of systems and mechanisms of marine fishing vessels is tread protection. To increase the effectiveness of tread protection, it is necessary to improve the methods of technical diagnostics of treads in order to use new methods at ship repair plants and marine vessels. It is proposed to use control electrodes made of stainless steel for technical diagnostics of marine vessel protectors. Laboratory tests of a stainless steel electrode and a standard silver chloride reference electrode were performed. The experiment took place at the installation for technical diagnostics of marine protectors, which was specially developed at the Department of “Power Plants and Electrical Equipment of Ships” of the Kamchatka State Technical University. Control measurements of the potential of the working protector were performed for five days, while 50 single control measurements of the working potential of the protector were performed daily using each electrode. The accuracy of the measurement results was evaluated using a mathematical and statistical method. The results of diagnosing the potential of the tread, obtained using an electrode made of stainless steel, comply with regulatory requirements. The proposed type of electrode can be used by ship crews for technical diagnostics of marine vessel protectors.

protection of ships, tread protection against corrosion, protectors working potential, protectors technical diagnostics, measuring the working potential of a protector, standard reference electrode, non-standard reference electrode

Introduction

The corrosion studies carried out by the authors [1, 2] on Kamchatkaꞌs sea-going vessels, have brought to light many cases of using low-quality protectors at these vessels. For this reason, the workers of small ship-repair enterprises of the Kamchatka Region applied to Kamchatka State Technical University with a request to develop a simple method for technical diagnostics of ship protectors in order to check their working capacity.

According to the standard requirements [3], when technically diagnosing ship protectors it is necessary to measure their operating potential and current output. These tread characteristics are assessed using an expensive set of devices [3]. It should be noted that standard methods [1, 4-10] of protector quality control are not intended for continuous non-destructive testing of individual marine protectors. It is also necessary to take into account the experience of using silver-chloride reference electrodes (CRE) on Kamchatkaꞌs sea-going vessels to measure the operating potential of protectors. No shipꞌs crew of Kamchatka fleet uses CRE in their practical work [11]. This is because of the high cost of CRE and the complexity of its storage. For this reason, it is necessary to stop using CRE when organizing incoming quality control of marine protectors and replace it with a non-standard control electrode intended for use at small ship repair enterprises and sea-going vessels.

The papers [12-17] present the results of tests of non-standard control electrodes (of aluminum, copper; electrodes made of shipꞌs hull steel, etc.) used to control the tread protection systems of sea-going vessels’ hulls. This paper presents the results of technical diagnostics of protectors using a control electrode made of stainless steel.

The purpose of the article is to exchange experience in the quality control of marine protectors.

Еxperimental part

For five days (from 11.14.2022 to 11.18.2022), the operating potential of a P-SSA-4 type protector made of AP-1 aluminum alloy was measured in the laboratory conditions. The measurements were performed using a UNI-T UT39E+ multimeter and two electrodes:

– CRE;

– a control electrode made of CR (chrome) 17 stainless steel in accordance with the recommendations of the regulatory document [3].

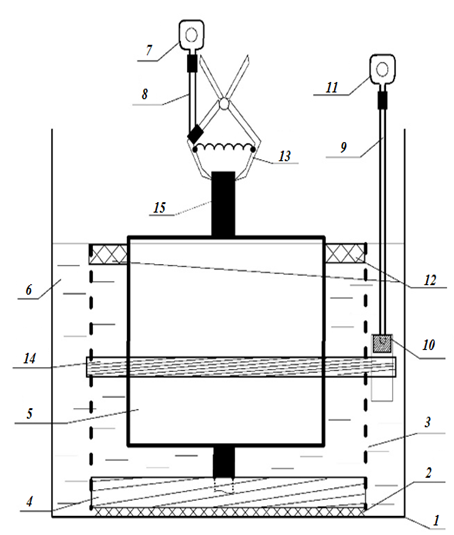

Fifty single measurements of the tread potential were carried out daily using each control electrode. The total time for carrying out daily measurements is approximately 10 minutes. A diagram of the installation for technical diagnostics of sea-going vessel protectors is shown in Fig. 1. This installation was developed at the department “Power Plants and Electrical Equipment of Ships” of the Federal State Budgetary Educational Institution of Higher Education “Kamchatka State Technical University”. The installation contains a steel container 1 filled with sea water 6. In the center of the steel container, there is a dielectric perforated container 3, which is attached to the steel container 1 using an adhesive connection 2. At the bottom of the perforated container 3, there is an elastic dielectric lining 4 made from foam-rubber. The perforated dielectric container 3 contains a replaceable controlled protector 5 fixed in the vertical position with the help of a float 12 made of dielectric material. A measuring cable 8 is connected to the steel armature 15 of the controlled protector through a spring-loaded self-clamping contact (of crocodile type) 13. A cable tip 7 is soldered to the free end of the measuring cable 8. A measuring cable 9 is soldered to the control electrode 10, besides the soldering point is protected with VK-9 glue. A cable tip 11 is soldered to the free end of the measuring cable 9 of the control electrode 10. The control electrode 10 is attached to the perforated container with the help of a rubber clamping ring 14.

Fig. 1. The design of an installation for technical

diagnostics of marine vessel protectors

The experiment has been performed the following way:

– the steel container was filled with sea water to the specified level;

– the controlled protector was placed in the perforated dielectric container in the vertical position which was fixed with the help of a dielectric float;

– the measuring cable equipped with a cable tip was connected to the steel armature of the protector with the help of a self-clamping contact;

– the electrode was placed in seawater, and attached to a perforated container with the help of a rubber clamping ring;

– 5 minutes after placing the controlled protector in sea water, the potential difference (ΔU) between the protector and the reference electrode was measured, 50 control measurements being performed with a pause of about 5 seconds between measurements, according to the recommendations [18-22];

– the obtained measurement results were entered into special forms, the experimental data were digitized, and initial mathematical processing of the measurement results was carried out with the help of the Microsoft Office Excel 365 software product;

– after processing the measurement results, electrode No. 1 was removed from the electrical measuring circuit, and electrode No. 2 was attached;

– then the measurement cycle was repeated with the help of control electrode No. 2, according to the recommendations proposed in papers [18-22].

It is worth noting that in order to connect the electrode test wire to an electrical measuring instrument (multimeter), one can use a bolted connection, a built-up connection, or a simple cable tip. The UNI-T UT39E+ multimeter was used in the experiment, but other electrical measuring instruments can also be used.

Results of the experiment and discussion

The results of the experiment and assessment of their metrological characteristics with the help of mathematical and statistical methods [23], obtained on the above installation by means of two control electrodes, are given in the Table (Uav – simple average, mV; R – variation range; d – average linear deviation; D – dispersion; σ – average quadratic deviation; Kd – linear variation coefficient, %; Kr – oscillation coefficient, %; V – variation coefficient, %) and in Fig. 2, 3.

Results of monitoring the working potential of P-KOA-4 protector from 11/14/2022 to 11/18/2022

|

No.

|

Results of measurements of the potential difference between the protector |

|||||||||

|

Electrode No. 1 CRE |

Electrode No. 2 made from stainless steel |

|||||||||

|

14/11/2022 |

15/11/2022 |

16/11/2022 |

17/11/2022 |

18/11/2022 |

14/11/2022 |

15/11/2022 |

16/11/2022 |

17/11/2022 |

18/11/2022 |

|

|

1 |

939 |

945 |

941 |

933 |

947 |

393 |

390 |

383 |

375 |

388 |

|

2 |

939 |

946 |

942 |

933 |

948 |

393 |

390 |

383 |

374 |

388 |

|

3 |

939 |

945 |

942 |

933 |

948 |

393 |

390 |

383 |

375 |

388 |

|

4 |

939 |

946 |

941 |

932 |

948 |

393 |

390 |

382 |

374 |

388 |

|

5 |

939 |

945 |

942 |

932 |

947 |

393 |

390 |

383 |

375 |

388 |

|

6 |

939 |

946 |

941 |

932 |

948 |

393 |

390 |

382 |

374 |

387 |

|

7 |

939 |

945 |

942 |

932 |

948 |

393 |

390 |

382 |

375 |

387 |

|

8 |

939 |

946 |

942 |

932 |

947 |

393 |

390 |

383 |

374 |

387 |

|

9 |

939 |

946 |

942 |

932 |

948 |

393 |

390 |

383 |

375 |

388 |

|

10 |

939 |

946 |

942 |

932 |

948 |

394 |

390 |

383 |

374 |

388 |

|

11 |

939 |

946 |

942 |

932 |

947 |

394 |

390 |

383 |

375 |

388 |

|

12 |

939 |

946 |

942 |

932 |

948 |

394 |

390 |

383 |

374 |

388 |

|

13 |

939 |

946 |

942 |

932 |

948 |

394 |

390 |

383 |

375 |

388 |

|

14 |

939 |

946 |

942 |

932 |

948 |

394 |

390 |

383 |

374 |

388 |

|

15 |

939 |

946 |

942 |

932 |

948 |

394 |

390 |

383 |

375 |

387 |

|

16 |

940 |

946 |

942 |

932 |

948 |

394 |

390 |

383 |

374 |

387 |

|

17 |

939 |

946 |

942 |

932 |

948 |

394 |

390 |

383 |

375 |

387 |

|

18 |

940 |

946 |

942 |

932 |

948 |

394 |

390 |

383 |

374 |

388 |

|

19 |

939 |

946 |

942 |

932 |

948 |

394 |

390 |

383 |

375 |

388 |

|

20 |

939 |

946 |

942 |

932 |

948 |

394 |

390 |

383 |

374 |

388 |

|

21 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

22 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

23 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

24 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

25 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

26 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

27 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

28 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

29 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

30 |

940 |

946 |

943 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

31 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

32 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

33 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

34 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

35 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

36 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

37 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

38 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

39 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

40 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

41 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

42 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

43 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

44 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

45 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

46 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

47 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

48 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

49 |

940 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

374 |

388 |

|

50 |

939 |

946 |

942 |

932 |

948 |

394 |

391 |

383 |

375 |

388 |

|

Uav, mV |

939.34 |

945.92 |

941.96 |

932.06 |

947.92 |

393.82 |

390.60 |

382.94 |

374.52 |

387.88 |

|

R |

1.00 |

1.00 |

2.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

|

d |

0.45 |

0.15 |

0.12 |

0.11 |

0.15 |

0.30 |

0.48 |

0.11 |

0.50 |

0.21 |

|

D |

0.22 |

0.07 |

0.08 |

0.06 |

0.07 |

0.15 |

0.24 |

0.06 |

0.25 |

0.11 |

|

σ |

0.48 |

0.27 |

0.28 |

0.24 |

0.27 |

0.39 |

0.49 |

0.24 |

0.50 |

0.33 |

|

Kd, % |

0.05 |

0.02 |

0.01 |

0.01 |

0.02 |

0.07 |

0.12 |

0.03 |

0.13 |

0.05 |

|

Kr, % |

0.11 |

0.11 |

0.21 |

0.11 |

0.11 |

0.25 |

0.26 |

0.26 |

0.27 |

0.26 |

|

V, % |

0.05 |

0.03 |

0.03 |

0.03 |

0.03 |

0.10 |

0.13 |

0.06 |

0.13 |

0.08 |

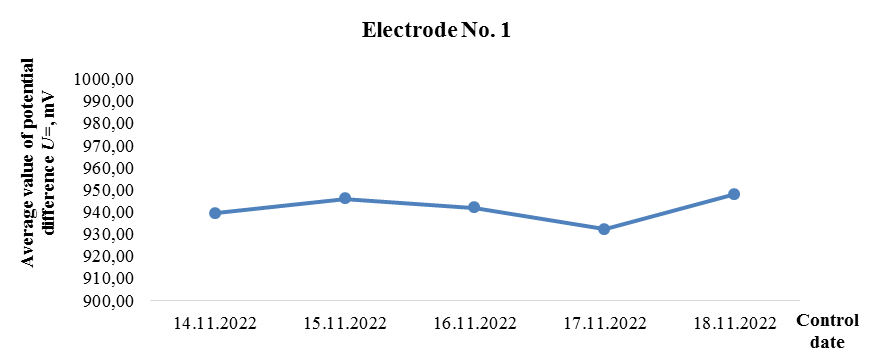

Fig. 2. Dynamics of the results of the potential difference measuring in the period

from November 14, 2022 to November 18, 2022, obtained with the help of electrode No. 1 (CRE)

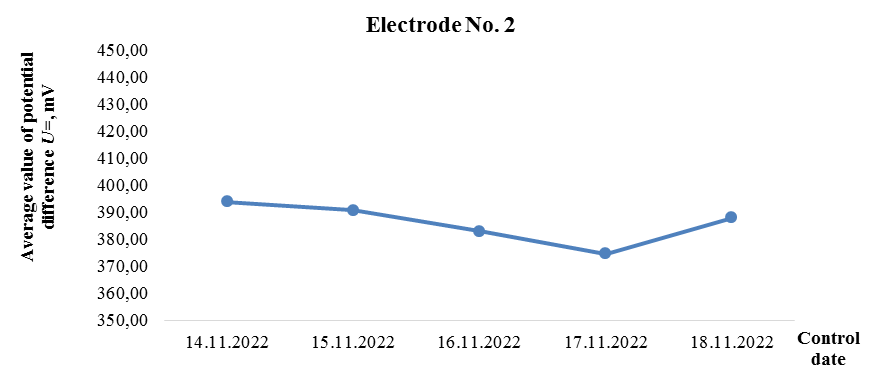

Fig. 3. Dynamics of the results of the potential difference measuring in the period

from November 14, 2022 to November 18, 2022, obtained with the help of electrode No. 2 made of stainless steel

The results of the experiment given in the Table show that each group of measurements is homogeneous, the degree of dispersion of the measurement results is insignificant, since V < 1%. The dynamics of changes in the results of the potentialꞌs measurements over the period of the experiment is illustrated in Fig. 2, 3.

The results of the experiment given in Fig. 2, 3, show the following:

– repeatability (convergence) of the control measurement results corresponds to the accuracy category of “precise measurements”, since the variation coefficient V, %, has proved to be less than 1% [23];

– intra-laboratory precisionness [24] of measurement results meets the requirement: |Xmax – Xmin| = |948 – 932| = 16 ≤ 20 mV [10].

The results of measuring the protectorꞌs working potential, obtained with the help of the control electrode made of stainless steel, have shown the following:

– repeatability (convergence) of the control measurement results, according to [23], corresponds to the accuracy category of “precise measurements”, since the variation coefficient V, %, has proved to be less than 1%;

– intra-laboratory precisionness [24] of measurement results complies with the condition: |Xmax – Xmin| = |394 – 374| = 20 ≤ 20 mV [10].

Conclusion

1. The results of monitoring the protectorꞌs potential obtained with the help of an electrode made of stainless steel, comply with standard requirements.

2. The results of the research can be used in training operators for technical diagnostics of sea-going vessels and shipsꞌ protectors.

1. Shvetsov V. A., Belov O. A., Belozerov P. A., Shun'kin D. V. Kontrol' sistem protektornoi zashchity stal'nykh sudov i korablei: monografiia [Control of tread protection systems of steel vessels and ships: monograph]. Petropavlovsk-Kamchatskii, Izd-vo KamchatGTU, 2016. 109 p.

2. Iastrebov D. P., Belov O. A., Shvetsov V. A., Belavina O. A. O vybore elektrodov dlia kontrolia sistem protektornoi zashchity stal'nykh sudov i korablei [About the choice of electrodes for monitoring the tread protection systems of steel vessels and ships]. Vestnik Astrakhanskogo gosudarstvennogo tekhnicheskogo universiteta. Seriia: Morskaia tekhnika i tekhnologiia, 2019, no. 4, pp. 39-45.

3. ISO 15589-2-12. Petroleum, petrochemical and natural gas industries - Cathodic protection of pipeline transportation systems. Available at: https://www.iso.org/standard/51992.html (accessed: 28.07.2023).

4. Zobochev Iu. E., Solinskaia E. V. Zashchita sudov ot korrozii i obrastaniia [Protection of ships from corrosion and fouling]. Moscow, Transport Publ., 1984. 174 p.

5. Korobtsov I. M. Tekhnicheskoe obsluzhivanie i remont flota [Fleet maintenance and re-pair]. Moscow, Transport Publ., 1975. 195 p.

6. RD 31.28.10-97. Kompleksnye metody zashchity sudovykh konstruktsii ot korrozii [Complex methods of ship structures protection from corrosion]. Moscow, TsNIIMF Publ., 1997. 169 p.

7. GOST 9.056-75. Stal'nye korpusa korablei i sudov. Obshchie trebovaniia k elektrokhi-micheskoi zashchite [Steel hulls of ships and vessels. General requirements for electrochemical protection]. Moscow, Izd-vo standartov, 1986. 20 p.

8. GOST 26501-85. Korpusa morskikh sudov. Obshchie trebovaniia k elektrokhimicheskoi zashchite [Hulls of sea vessels. General requirements for electrochemical protection]. Moscow, Izd-vo standartov, 1985. 7 p.

9. Chandler K. A. Marine and Offshore Corrosion. London; Boston, Butterworths, 1985. 413 p. (Chendler K. A. Kor-roziia sudov i morskikh sooruzhenii / per. s angl. I. A. Barkhatova, V. I. Lemkova. L.: Sudostroenie, 1988. 320 s.).

10. RZK-NK-01. Rukovodstvo po zashchite korpusov navodnykh korablei VMF ot korrozii i obrastaniia [Guidelines for protecting the hulls of Naval surface ships from corrosion and fouling]. Moscow, Voennoe izd-vo, 2001. 258 p.

11. Iastrebov D. P., Belov O. A., Shvetsov V. A., Ushakevich A. P., Kuznetsov G. V. O tselesoobraznosti ispol'zovaniia khlorserebrianykh elektrodov dlia kontrolia sistem protektornoi zashchity stal'nogo korpusa sudna. Tekhnicheskaia ekspluatatsiia vodnogo trans-porta: problemy i puti razvitiia [On the expediency of using silver chloride electrodes to control the systems of protective protection of the steel hull of the vessel. Technical operation of water transport: problems and ways of development]. Materialy Mezhdunarodnoi nauchno-prakticheskoi konferentsii (Petropavlovsk-Kamchatskii, 23-25 oktiabria 2019 g.). Petropavlovsk-Kamchatskii, Izd-vo KamchatGTU, 2020. Pp. 121-124.

12. Iastrebov D. P., Shun'kin D. V., Rogozhnikov A. O., Kuznetsov G. V. K voprosu ispol'zovaniia tsinkovykh elektrodov dlia kontrolia protektornoi zashchity sudov i korablei [On the issue of using zinc electrodes to control the tread protection of ships and ships]. Vestnik Astrakhanskogo gosudarstvennogo tekhnicheskogo universiteta. Seriia: Morskaia tekhnika i tekhnologiia, 2021, no. 2, pp. 16-23.

13. Iastrebov D. P., Belov O. A., Shvetsov V. A., Belavina O. A., Zaitsev S. A. K voprosu ispol'zovaniia sta'nykh plastin dlia kontrolia protektornoi zashchity korpusov sudov i korablei. Tekhnicheskaia ekspluatatsiia vodnogo transporta: problemy i puti razvitiia [On the issue of using steel plates to control the tread protection of ship hulls and ships. Technical operation of water transport: problems and ways of development]. Materialy Mezhdunarodnoi nauchno-prakticheskoi konferentsii (Petropavlovsk-Kamchatskii, 23-25 oktiabria 2019 g.). Petropavlovsk-Kamchatskii, Izd-vo KamchatGTU, 2020. Pp. 125-129.

14. Iastrebov D. P., Belov O. A., Shvetsov V. A., Tarabanov B. V., Zaitsev S. A. K voprosu ispol'zovaniia elektrodov iz sudokorpusnoi stali dlia kontrolia zashchishchennosti ot korrozii korpusov sudov i korablei [On the issue of using electrodes made of ship-hull steel to control the corrosion protection of ship hulls and ships]. Vestnik Astrakhanskogo gosudarstvennogo tekhnicheskogo universiteta. Seriia: Morskaia tekhnika i tekhnologiia, 2020, no. 2, pp. 15-21.

15. Iastrebov D. P., Belov O. A., Shvetsov V. A., Ushakevich A. P., Kuznetsov G. V., Tarabanov B. V. K voprosu ispol'zovaniia aliuminievykh elektrodov dlia kontrolia zashchishchennosti ot korrozii stal'nykh korpusov sudov i korablei [On the issue of using aluminum electrodes to control corrosion protection of steel hulls of ships and ships]. Vestnik Astrakhanskogo gosudarstvennogo tekhnicheskogo universiteta. Seriia: Morskaia tekhnika i tekhnologiia, 2021, no. 3, pp. 23-32.

16. Iastrebov D. P. K voprosu ispol'zovaniia mednykh elektrodov dlia kontrolia zashchishchennosti ot korrozii stal'nykh korpusov sudov i korablei [On the issue of using copper electrodes to control corrosion protection of steel hulls of ships and ships]. Vestnik Astrakhanskogo gosudarstvennogo tekhnicheskogo universiteta. Seriia: Morskaia tekhnika i tekhnologiia, 2021, no. 4, pp. 43-51.

17. Iastrebov D. P. K voprosu izgotovleniia tsinkovykh elektrodov sravneniia dlia morskikh sudov i korablei [On the issue of manufacturing zinc comparison electrodes for marine vessels and ships]. Vestnik Astrakhanskogo gosudarstvennogo tekhnicheskogo universiteta. Seriia: Morskaia tekhnika i tekhnologiia, 2022, no. 4, pp. 38-46.

18. Belov O. A., Shvetsov V. A., Iastrebov D. P. Obosnovanie optimal'noi periodichnosti kontrolia raboty protektornoi zashchity stal'nykh korpusov sudov [Substantiation of the optimal frequency of monitoring the work of the tread protection of steel hulls of ships]. Ekspluatatsiia morskogo transporta, 2017, no. 1 (82), pp. 41-48.

19. Belov O. A., Shvetsov V. A., Iastrebov D. P., Belavina O. A., Shun'kin D. V. Vnedrenie usovershenstvovannogo sposoba kontrolia sistem protektornoi zashchity stal'nykh korpusov sudov Kamchatskogo flota [Introduction of an improved method for monitoring the tread protection systems of steel hulls of the Kamchatka Fleet vessels]. Vestnik Kamchatskogo gosudarstvennogo tekhnicheskogo universiteta, 2017, no. 39, pp. 6-11.

20. Shvetsov V. A., Belov O. A., Belavina O. A., Iastrebov D. P. Obosnovanie vozmozhnosti iskliucheniia vneshnego osmotra sistem protektornoi zashchity stal'nykh korpusov sudov [Justification of the possibility of excluding the external in-spection of the tread protection systems of steel hulls of ships]. Vestnik Astrakhanskogo gosudarstvennogo tekhnicheskogo universiteta. Seriia: Morskaia tekhnika i tekhnologiia, 2017, no. 1, pp. 29-38.

21. Belozerov P. A., Shvetsov V. A., Belavina O. A., Shun'kin D. V., Korostylev D. V., Pakhomov V. A., Malinovskii S. A. Obosnovanie sposoba vybora kontrol'nykh tochek dlia izmereniia zashchitnogo potentsiala stal'nykh korpusov korablei i sudov [Justification of the method of selecting control points for measuring the protective potential of steel hulls of ships and vessels]. Vestnik Kamchatskogo gosudarstvennogo tekhnicheskogo universiteta, 2014, no. 28, pp. 6-11.

22. Shvetsov V. A., Belozerov P. A., Belavina O. A., Shun'kin D. V., Malinovskii S. A. Obosnovanie vybora neobkhodi-mogo chisla parallel'nykh izmerenii zashchitnogo poten-tsiala stal'nykh korpusov korablei i sudov v kontrol'noi tochke [Justi-fication of the choice of the required number of parallel measurements of the protective potential of steel hulls of ships and vessels at the control point]. Vestnik Kamchatskogo gosudarstvennogo tekhnicheskogo universiteta, 2016, no. 35, pp. 40-46.

23. GOST R 8.736-2011. Gosudarstvennaia sistema obespecheniia edinstva izmerenii (GSI). Izmereniia priamye mnog-okratnye. Metody obrabotki rezul'tatov izmerenii. Osnovnye polozheniia [The State system of ensuring the uniformity of measurements (GSI). Direct multiple measurements. Methods of processing measurement results. Basic provisions]. Available at: http://docs.cntd.ru/document/1200089016 (accessed: 28.07.2023).

24. Smagunova A. N. Shmeleva E. I., Shvetsov V. A. Algoritmy operativnogo i statistiche-skogo kontrolia kachestva raboty analiticheskoi laboratorii: metodicheskoe rukovodstvo [Algorithms of operational and statistical quality control of the analytical laboratory: methodological guide]. Novosibirsk, Nauka Publ., 2008. 60 p.