Russian Federation

Russian Federation

In accordance with ISS 32744-2014 “Frozen small fish. Technical conditions” shelf life of frozen sprat is no more than 6 months. At the same time, in the process of storing frozen sprat in the terms established by the regulatory document, the presence of surface and subcutaneous yellowing is noted, which significantly reduces the quality and demand for this type of product. The purpose of the work was to identify the causes of yellowing of frozen sprat and to propose ways to prevent their occurrence. It is shown that the common keel caught in the spring contains about 5% fat and retains high quality throughout the shelf life established in ISS 32744-2014 “Small frozen fish. TC”. Common sprats of the autumn fishing period contain an average of 8% fat and retain quality when stored frozen for four months. At the end of this period, a gradually increasing surface trend appears. Sprats of the winter fishing period are characterized by an increased level of fat retention (14%) and retain quality in frozen form for no more than three months. Based on changes in the quality indicators of fat of ice cream sprat during storage, it was found that the formation of surface and subcutaneous yellowing is influenced not only by an increase in the acid number of fat, as previously thought, but also by the aldehyde number. The need for work to increase the shelf life of ice cream sprat was justified, taking into account the season of production (catch), followed by amendments to ISS 32744-2014 “Small frozen fish. TC”.

sprat, yellowing of the surface, lipids, organoleptic indicators

Introduction

Active fishing of common sprat (Clupeonella cultriventris caspia Svetovidov, 1941), anchovy sprat (Clupeonella engrauliformi Borodin, 1904) and bigeye sprat (Clupeonella grimmi Kessler, 1877) in the Caspian Sea contributes to the development of technologies for processing of these fish species taking into account species characteristics [1]. Significantly, increased volumes of harvested sprat and high quality of raw materials make it possible to produce a wide range of food fish products. At the same time, despite the observance of technological regimes fishing organizations are faced with a number of defects: in the process of storage in compliance with the rules and regimes do ISS 32744-2014 “Small frozen fish establish found surface and subcutaneous yellowing of the surface of fish within the shelf life. Technical conditions” [2]. In this regard, the preservation of high quality of frozen raw materials with an active enzyme system, which include Caspian Sea sprat, is extremely important. It is generally believed that the quality of frozen fish during storage is affected by desiccation, which causes hardness and dryness of the fish surface, and fat oxidation, which contributes to the acquisition of rancid taste and unpleasant odor. During storage, the lipids of raw materials are subject to hydrolytic and oxidative processes. If storage conditions are not met, the process of hydrolysis is accelerated and, because of the action of molecular oxygen and biochemical oxidation of unsaturated fatty acids of lipids due to the action of lipoxygenase enzymes, there are deep and irreversible changes in raw materials that reduce quality. Oxidative changes in fats lead to the loss of lipophilic vitamins (A, D, E, K), essential fatty acids (linoleic, linolenic, arachidonic acids) and other biologically active substances [3]. The intensity of these processes depends on a variety of factors, including the initial state of the raw material to be processed, the packaging used, temperature and conditions of further storage. Modern studies indicate that when choosing methods of fish processing it is necessary to take into account the period of extraction (catch) [4].

In accordance with the currently valid ISS 32744-2014 “Frozen small fish. Technical conditions” shelf life of frozen sprat without division into types and catching periods is recommended not more than 6 months [5]. The quality of small frozen fish is determined organoleptic: by determining the characteristic odor, taste, and the presence of surface and subcutaneous yellowing. However, surface yellowing of frozen sprat surface is often noted at the beginning of frozen storage.

Earlier studies conducted by scientists on anchovy sprat from the Caspian Sea indicated that subcutaneous yellowing of frozen sprat with a shelf life of 3 months is due to the presence of the pigment taraxanthin. The studies indicated that the skin of freshly caught ancho sprat contained 1.35-1.5% mg of caratinoid substances, while the fat extracted from muscle tissue contained 0.2 to 0.3% mg of caratinoids. After a short-term freezing process of 6 hours at a temperature of –18 °C, the skin contains from 0.2 to 0.3% mg of caratinoid substances, while in tissue fat their amount is from 1.3 to 1.4% mg, which indicates the migration of these substances from the skin to muscle tissue during freezing and storage [3]. Accordingly, surface yellowing, which is detected at the beginning of storage, is not associated with oxidative processes and is not a factor indicating a decrease in fish quality. Earlier studies were based on the technological characteristics of the anchovy sprat population, as this object was the basis of the fishery.

At present, the main share of catches is common sprat. The maximum production of common sprat by a multi-depth trawl was reached in 2023 and amounted to 31.8 thousand tons, which is higher than ever in the last 20 years. In this connection, the research on establishing the causes of yellowing was carried out for the common sprat with the establishment of shelf life of frozen food products from it.

The aim of the work is to identify the causes of yellowing of frozen sprat and to propose ways to prevent their occurrence.

Objects and methods of research

Frozen common sprat from the spring, fall and winter periods of the marine commercial fishery (trawl catches of the vessel “Sailor's star”) was used as the objects of the study.

Sampling was carried out in accordance with GOST 31339-2006 [6]. Organoleptic characteristics were investigated by the method of sensory analysis with subsequent construction of profilograms. The intensity of change in organoleptic parameters (odor, consistency, subcutaneous yellowing, surface yellowing, and gloss) during storage at a temperature

of –18 °C for 6 months was evaluated on a five-point scale (Table 1).

Table 1

Organoleptic evaluation of frozen sprat quality in the process of storage

|

Mark |

Characteristics |

||||

|

Smell |

Consistency |

Subdermal yellowing |

Superficial yellowing |

Surface lustre |

|

|

5 |

Neutral |

Elastic, dense |

Vividly expressed |

Vividly expressed over the entire surface of the muscle tissue |

Vividly expressed, surface clean, without spots |

|

4 |

Slightly |

Dense |

Present over the entire surface of the fish |

Present over the entire surface of the muscle tissue |

Lustre present, surface clean |

|

3 |

Moderately |

Not smearing, weakened |

Present in fish belly |

Present in fish belly and head area |

Lustre partially present |

|

2 |

Moderately |

Not significantly weakened |

Present on the belly |

Present on the entire surface |

Not homogeneous |

|

1 |

Distinctly |

Weakened |

Slight presence on the surface of the fish body |

Slight presence in the abdomen area of the fish |

Fish surface tarnished |

|

0 |

Unpleasant, foreign odour present |

Significantly weakened |

Absent over the entire surface of the fish |

Absent over the entire surface of the fish |

Absent |

Fat content in muscle tissue was determined according to ISS 7636-85 [7]. Determination of fat quality indicators (acid, aldehyde number) of frozen sprat was carried out on the fifth (control), thirtieth day and subsequently every month during 6 months of storage at a temperature of –18 °C in accordance with methodological guidelines 4.2.1847-04 “Sanitary-epidemiological evaluation of justification of shelf life and storage conditions of food products” [8]. Preparation of samples for determination of fatty acid composition of fat was carried out according to ISS 31665-12 [9], fatty acids content was determined according to ISS 31663-2012 on chromatograph Kristall 5000 [10]. Acid number of fat was determined by titrimetric method according to ISS 7636-85 [7]. Aldehyde number was determined on a photocolorimeter. Microbiological parameters (QMAFAnM, BLCP, S.aureus, sulfite-reducing clostridia, listeria and V. rarapoliticus) were determined according to ISS 10444.15-94, ISS 31746-2012, ISS 31747-2012 [11-13]. Mathematical processing of the obtained results was carried out in Microsoft Excel by calculating correlation dependencies using the nonlinear regression method.

Results and discussion

The study of changes in organoleptic parameters of common sprat stored for 180 days at a temperature of –18 °C, without glazing, packed in a polyethylene bag, harvested in the spring, autumn and winter fishing periods showed that the surface of the studied frozen blocks during the first month of storage is frequent, without signs of oxidation and foreign odor.

Surface yellowing of common sprat appears in the first month of storage and is distributed over the entire surface of the fish body, foreign odor is absent, and consistency is elastic. After four months of storage at a temperature of –18 °C, surface and subcutaneous yellowing was observed in common sprat from the fall and winter fishing periods (Fig. 1).

а b

Fig. 1. Increase in yellowing of the muscle tissue of common sprat during storage:

a – storage for 120 days; b – storage for 180 days

During storage of common sprat at –18 °C, subcutaneous yellowing of muscle tissue is not uniform: it starts from the abdomen and gradually increases to the tail part of the body (Fig. 1).

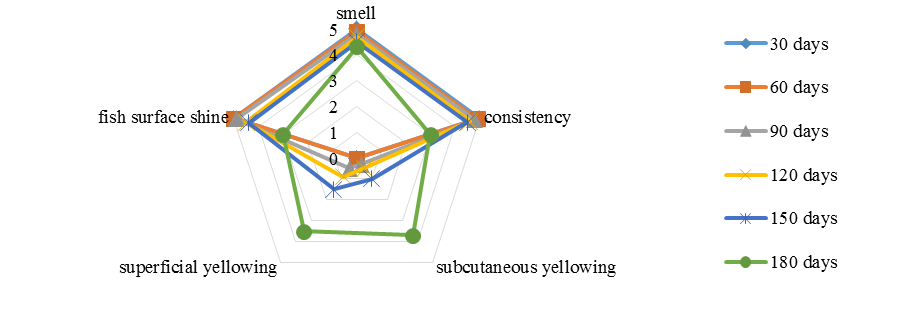

The process of surface and subcutaneous yellowing in the common sprat caught in different periods of prey proceeds with different intensity. The change in the organoleptic profile based on the organoleptic quality assessment score of frozen common sprat (Table 1) from the spring catch period during storage is shown in Fig. 2.

Fig. 2. Changes in the organoleptic profile of common sprat during

the spring fishing period at a temperature of –18 ºC

The fat content in the muscle tissue of common sprat from the spring fishing period is 4.88 % (± 0.05). Organoleptic characteristics begin to change insignificantly after 180 days of storage at –18 °C. Accordingly, the common sprat caught in the spring fishing period during 6 months keeps the quality indicators established in ISS 32744-2014 “Small frozen fish. Techni-

cal conditions” [5].

Common sprat caught in the fall fishery contains twice as much fat in muscle tissue 8.2 % (± 0.05) compared to spring-caught common sprat, which is reflected in its organoleptic characteristics during frozen storage (Fig. 3).

Fig. 3. Changes in the organoleptic profile of common sprat during

the autumn fishing period at a temperature of –18 ºC

Common sprat of autumn fishery retains organoleptic characteristics during the shelf life established by ISS 32774-2014 “Fish small frozen terms. TC” [5]. At the same time, after 120 days of storage luster of fish surface is lost, slight yellowing of fish surface is observed. The consistency of muscle tissue elastic, the smell of fish is weakly expressed. After 150 days of storage, deterioration of organoleptic characteristics is observed: surface and subcutaneous yellowing, the consistency of fish becomes weaker.

More intense surface and subcutaneous yellowing is found in the common sprat from the winter period of catch, the fat content in the muscle tissue of which is at the level of 14.5% (±0.03). After 3 months of storage at a temperature of –18 °C yellowing is found on the surface of fish with further penetration of yellowing into the subcutaneous layers of muscle, with the formation of odor characteristic of oxidative processes of fat. Oxidative processes are more active in fish in the superficial layers of the block. Changes in the organoleptic profile of common sprat from the winter period of fishing at a temperature of –18 °C are shown in Fig. 4.

Fig. 4. Change in the organoleptic profile of common sprat during the winter fishing period at a temperature of –18 ºC

Oxidative and hydrolytic processes during storage of frozen common sprat show different changes in organoleptic parameters depending on the fatty acid composition. The data presented in Table 2 indicate changes in the fatty acid composition of common sprat by season of fishing, physiological processes cause this fact: the spring period is characterized by maturation of gonads; nutrients are spent on the formation and maturation of sexual products [14].

Table 2

Fatty acid composition of common sprats, %

|

Acid |

Common sprat from the marine fishery |

|

|

spring |

winter |

|

|

Saturated fatty acids (SFA) |

||

|

Myristic acid (С14:0) |

3.8 |

2.56 |

|

Palmitic acid (С16:0) |

22.7 |

19.08 |

|

Stearic acid (С18:0) |

5.1 |

4.94 |

|

Arachinoic acid (С20:0) |

0.2 |

0.2 |

|

Behenoic acid (С22:0) |

0.2 |

0.18 |

|

Total saturated fatty acids |

32.0 |

26.78 |

|

Monounsaturated fatty acids (MNFA) |

||

|

Miristoleic acid (С14:1) |

0.3 |

0.8 |

|

Palmitoleic acid (С16:1) |

5.8 |

12.1 |

|

Oleic acid (С18:1) |

33.6 |

32.3 |

|

Elaidinic acid (С18:1t) |

0.1 |

– |

|

Erucic acid (С22:1) |

0.1 |

0.15 |

|

Total monounsaturated acids |

39.9 |

45.35 |

|

Polyunsaturated fatty acids (PUFA) |

||

|

Linoleic acid (С18:2) |

1.6 |

3.04 |

|

linolenic acid (С18:3) |

0.2 |

0.11 |

|

Alpha-Linolenic acid (C18:3) |

1.8 |

1.5 |

|

Eicosatrienoic acid (С20:3n6c) |

0.1 |

0.16 |

|

Arachidonic acid (С20:4) |

0.6 |

0.62 |

|

Eicosapentaenoic acid (С20:5) |

5.3 |

10.25 |

|

Docosahexaenoic acid (С22:6) |

14.5 |

14.24 |

|

Total polyunsaturated fatty acids |

24.1 |

29.92 |

|

Correlation SFA: MNFA: NFA |

1.3 : 1.6 : 1 |

1 : 1.7 : 1.1 |

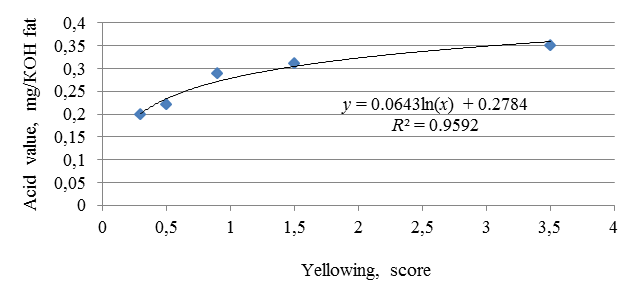

In the studied samples of sprat ordinary, the presence of 17 fatty acids was revealed. The spectrum of higher fatty acids is presented from myristic S14:0 to docosahexaenoic S22:6. According to the data obtained, MNFA and saturated fatty cysts constitute the main group of fatty acids of sprat lipids. The results obtained indicate a rather high level of PUFA content in the muscle tissue of sprat (24.1 in spring and 29.92 in winter, in %), while this group of fatty acids has a high sensitivity to oxidation due to the presence of unsaturated double bonds. Accordingly, the greater the PUFA content, the deeper the oxidative processes. In connection with the above, the accumulation of tissue fat hydrolysis products, to which free fatty acids belong was studied based on the change in the acid number of sprat fat of various production (catch) seasons during storage for 180 days at a temperature

of –18 °C (Fig. 5).

Fig. 5. Changes in the acid number of common sprat fat during storage

The increase in the acid number (Fig. 5) characterizes the amount of primary lipid oxidation products (peroxides and hydroperoxides). An intensive increase in the acid number occurs in the first 60 days, after which the intensity of the process decreases. At the same time, this trend does not depend on the period of catch of sprat.

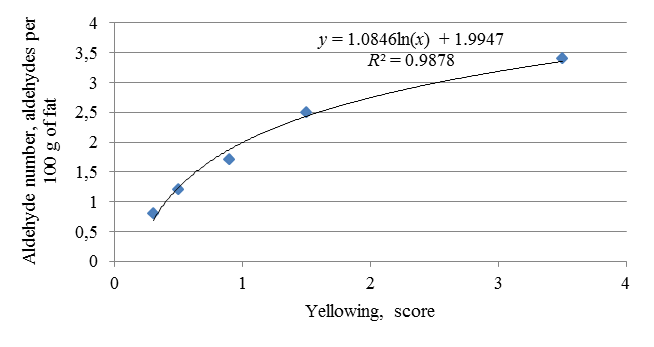

As you know, the process of oxidation of fish fats begins with unsaturated fatty acids with the formation of free radicals and peroxides; they contribute to the destruction of fish pigments, a change in the organoleptic properties of the product during storage. Carriers of a bitter taste and smell are volatile products of the breakdown of peroxides, mainly aldehydes. In this regard, during the studies, a change in the aldehyde number of sprat fat of ordinary storage for 180 days at a temperature of –18 °C was found (Fig. 6).

Fig. 6. Changes in the aldehyde number of common sprats during storage

Results of aldehyde number accumulation studies (Fig. 6) show a smooth increase in fat oxidation products throughout the storage period. In the first 60 days of storage, the accumulation of aldehydes occurs smoothly, with a sharp increase after 60 days of storage. The accumulation of oxidation products occurs faster in the raw materials of winter fishing. The data obtained are consistent with the results of organoleptic assessment: superficial and subcutaneous yellowing is visually detected at the third month of storage of raw materials. Previously published studies for a similar type of raw material indicate that an increase in the aldehyde number of ≈ 15 ‰ has a significant effect on the formation of superficial yellowing of anchovy sprat [15]. Studies and calculation of the correlation of the growth of aldehyde and acid chi-villages during storage on the appearance of surface and subcutaneous yellowing by non-linear regression indicate the same level of influence of these oxidative processes of fat (Fig. 7).

Fig. 7. Assessment of the degree of influence of oxidative fat processes on the appearance

of surface yellowing during storage of common sprats: a – effect of aldehyde number increase on surface yellowing;

b – effect of formation of acid number on formation of surface yellowing

Accordingly, the formation of superficial and subcutaneous yellowing during chilling is influenced not only by an increase in the acid number, but also by the aldehyde number, which must be taken into account when monitoring the quality of sprat when setting the timing of chilling. The quality of sprats during storage was also assessed by microbiological parameters. No yeast, molds, coliform bacterias, pathogenic microorganisms (including salmonella), S. aureus, sulfite-reducing clostridia, V. paranoliticus, Listeria were detected in the test samples during 180 days of storage. The number of mesophilic aerobic and facultative anaerobic microorganisms, CFU/cm3, g, does not exceed the limits established by technical regulations. During the time set in ISS 32744-2014 “Small frozen fish. ТC” [5] shelf life of sprat is safe in terms of microbiological indicators, regardless of the period of production (catch). To preserve the quality of ordinary sprats frozen in the 32744-2014 established by ISS “Small frozen fish. ТC” [5] shelf life should be taken into account for the period of production (catch), modern methods of treatment should be introduced into the technological process, which can slow down oxidative processes (ultra-high pressure treatment, exposure to ultrasound, use of protective coatings).

Conclusions

Preservation of sprat quality during storage is due to a combination of biochemical, chemical and physical factors. Studies have shown that when the sprat is frozen, processes similar to those that occur when the sprat is frozen by anchovy and bigeye: the formation of yellowing of the top of the fish is observed. Superficial yellowing, which is detected immediately after the process of fermentation of sprat, is due to the transition of the taraxanthin pigment from the skin to muscle tissue. The reason for the appearance of surface yellowing, which is found during the storage of sprats in frozen form after several months of storage, depends on the period of production (catch) and is a consequence of qualitative changes in fats. The fat content in sprat is subject to significant fluctuations over the seasons. Sprat, common, caught in the spring and autumn, belongs to medium-fat fish species, in winter – to fatty ones. The qualitative composition of sprat fat is also changing: in the spring, when the costs of the fish organism for the formation of sexual products occur, the level of MNFA and PUFA content decreases. The largest amount of PUFA was recorded in the oil of sprats of the ordinary winter period of production (catch), which must be taken into account when choosing processing methods and setting shelf life. When monitoring the quality of sprat during storage, it is necessary to take into account not only the change in the level of the acid number of fat, as previously thought, but also the change in the level of the aldehyde number of fat. The studies carried out indicate the need for further work on the establishment of methods for extending the shelf life of frozen sprat of autumn and winter washing by examining preservatives that slow down the processes of yellowing of ordinary sprat.

1. Kanat'ev S. V., Pomogaeva T. V., Kalmykov V. A., Razinkov V. P., Parickij Yu. A., Balchenkov I. B., Kamakin A. M., Shipulin S. V. Predposylki, organizatsiia i razvitie kilechnogo tralovogo promysla v Srednem Kaspii [Background, organization and development of keel trawling in the Middle Caspian Sea]. Trudy VNIRO, 2022, vol. 190, pp. 22-35. DOI:https://doi.org/10.36038/2307-3497-2022-190-22-35.

2. GOST 32744-2014. Ryba melkaia morozhenaia. Tekhnicheskie usloviia [The fish is small and frozen. Technical specifications]. Moscow, Standartinform Publ., 2019. 16 p.

3. Pavel'eva L. G., Vlasova V. V. Ob izmenenii karoti-noidov i produktov okisleniia v zhire kaspiiskoi kil'ki pri ee zamorazhivanii i kholodil'nom khranenii [On the changes in carotenoids and oxidation products in the fat of the Caspian sprat during its freezing and refrigerating storage]. Trudy VNIRO. Tekhnologiia i mekhanizatsiia obrabotki ryby i nerybnykh ob"ektov. Moscow, Izd-vo VNIRO, 1972. Pp. 5-13.

4. Puke S., Dmitrijeva O., Galoburda R. Influence of Pre-Treatment on the Seasonal Variation of Smoked Baltic Sprat Texture and Color. Applied Sciences, 2024, vol. 14 (2), p. 504.

5. GOST 32744-2014. Ryba melkaia morozhenaia. Tekhnicheskie usloviia [ISS 32744-2014. The fish is small and frozen. Technical specifications]. Moscow, Standartin-form Publ., 2019. 16 p.

6. GOST 31339-2006. Ryba, nerybnye ob"ekty i produktsiia iz nikh. Pravila priemki i metody otbora prob [ISS 31339-2006. Fish, non-volatile objects and products from them. Acceptance rules and sampling methods]. Moscow, Standartinform Publ., 2007. 15 p.

7. GOST 7636-85. Ryba. Morskie mlekopitaiushchie, morskie bespozvonochnye i produkty ikh pererabotki. Metody analiza [ISS 7636-85. Fish. Marine mammals, marine invertebrates and their processed products. Methods of analysis]. Moscow, Standartinform Publ., 1985. 121 p.

8. MUK 4.2.1847-04. Sanitarno-epidemiologicheskaia otsenka obosnovaniia srokov godnosti i uslovii khraneniia pishchevykh produktov [MG 4.2.1847-04. Sanitary and epidemiological assessment of the justification of shelf life and storage conditions of food products]. Moscow, Federal'nyi tsentr gossanepidnadzora Minzdrava Rossii, 2004. 31 p.

9. GOST 31665-12. Masla rastitel'nye i zhiry zhivotnye. Poluchenie metilovykh efirov zhirnykh kislot [ISS 31665-12. Vegetable oils and animal fats. Production of fatty acid methyl esters]. Moscow, Standartinform Publ., 2019. 11 p.

10. GOST 31663-2012 Masla rastitel'nye i zhiry zhivotnye. Opredelenie metodom gazovoi khromatografii massovoi doli metilovykh efirov zhirnykh kislot [ISS 31663-2012. Vegetable oils and animal fats. Determination by gas chromatography of the mass fraction of fatty acid methyl esters]. Moscow, Standartinform Publ., 2019. 11 p.

11. GOST 10444.15-94. Produkty pishchevye. Metody opredeleniia kolichestva mezofil'nykh aerobnykh i fakul'ta-tivno anaerobnykh mikroorganizmov [ISS 10444.15-94. Food products. Methods for determining the number of mesophilic aerobic and facultatively anaerobic microorganisms]. Moscow, Standartinform Publ., 2010. 7 p.

12. GOST 31746-2012. Produkty pishchevye. Metody vyiavleniia i opredeleniia kolichestva koagulazopolozhitel'nykh stafilokokkov i Staphylococcus aureus [ISS 31746-2012. Food products. Methods for detecting and quantifying coagulase-positive staphylococcus and Staphylococcus aureus]. Moscow, Standartinform Publ., 2013. 28 p.

13. GOST 31747-2012. Produkty pishchevye. Metody vyiavleniia i opredeleniia kolichestva bakterii gruppy kishechnykh palochek (koliformnykh bakterii) [ISS 31774-2012. Food products. Methods for detecting and quantifying the bacteria of the intestinal bacillus group (coliform bacteria)]. Moscow, Standartinform Publ., 2013. 20 p.

14. Kozlova N. V., Latunov A. A., Makarova E. G., Makhlun A. V. Fiziologo-biokhimicheskie izmeneniia kaspiiskoi obyknovennoi kil'ki (Clupeonella delicatula caspia Svetovidov) v razlichnye periody godovogo tsikla [Physiological and biochemical changes of the Caspian common sprat (Clupeonella delicatula caspia Svetovidov) in different periods of the annual cycle]. Vestnik Astrakhanskogo gosudarstvennogo tekhnicheskogo universiteta. Seriia: Rybnoe khoziaistvo, 2021, no. 2, pp. 116-124. DOI:https://doi.org/10.24143/2073-5529-2021-2-116-124.

15. Pavel'eva L. G., Vlasova V. V. Otsenka stepeni okisleniia zhira morozhenoi kaspiiskoi kil'ki [Assessment of the degree of fat oxidation of frozen Caspian sprat]. Trudy VNIRO. Voprosy ratsional'nogo rybnogo khoziaistva tekhnologii i mekhanizatsii v Kaspiiskom basseine. Moscow, Izd-vo VNIRO, 1974. Pp. 181-187.