Россия

Россия

Россия

Россия

К ощутимым отрицательным сторонам маломерных судов с подвесными лодочными моторами можно отнести высокий расход топлива по отношению к генерируемой мощности, а также их низкую экологическую ха-рактеристику, выраженную в вредных выбросах. При оценке воздействия влияния всего мирового флота на окружающую среду нельзя пренебрегать малолитражными маломерными судами по причине их массовой распространенности. Рассматриваются экспериментальные данные, направленные на улучшение экологических характеристик подвесного лодочного мотора за счет снижения вредных выбросов путем впрыска воды в мелкодисперсионной фазе во всасывающий коллектор двигателя. Проанализированы экологические характеристики при подаче воды во впускной коллектор четырехтактного подвесного лодочного мотора; исследована нормативно-техническая документация, касающаяся ограничения вредных выбросов на маломерных судах с подвесными лодочными моторами; рассмотрены существующие методы подачи воды во впускной коллектор четырехтактных двигателей и проведен патентный поиск. На двигатель подвесного лодочного мотора установлено устройство, генерирующее мелкодисперсионное туманообразное облако, проведена экспериментальная оценка содержания вредных выбросов в выхлопных газах в части таких компонентов, как угарный газ, углеводороды и оксиды азота при подаче воды во впускной коллектор четырехтактного подвесного лодочного мотора путем лабораторных измерений в малом опытовом бассейне и на открытом воздухе. Оценивается содержание вредных выбросов в выхлопных газах при подаче воды во впускной коллектор четырехтактного подвесного лодочного мотора. Проанализирован экологический эффект от установки устройства подачи воды во впускной коллектор четырехтактного подвесного лодочного мотора. Исследованы четырехтактный подвесной лодочный мотор мощностью 4 л.с и изменение его экологических характеристик при впрыске воды в цилиндр.

маломерное судно, подвесной лодочный мотор, экологические характеристики подвесных лодочных моторов, газоанализатор

Introduction

To date the number of small vessels with outboard motors (hereinafter referred to as OM) is rapidly increasing, motorboats are widely used not only by amateur fishermen and for recreation on the water, but increasingly in conditions of shallow waters, as the main fleet of enterprises of various industries, the type of activity of which is related to the conduct of work on inland waterways and other water areas. Аs a result, their overall impact on the environment increases, and harmful emissions increase. This is manifested in the degradation of water bodies, negative impact on flora and fauna, harmful effects on humans and deterioration of plant growth of aquatic flora. Therefore, improving environmental performance will help reduce the harmful effects of outboard boat motors on the biosphere. Improving environmental performance is an urgent and necessary task.

Harmful emissions and discharges in the exhaust gases of engines of marine, river and small vessels are an important problem for humanity and the environment. Harmful emissions and discharges contain toxic substances that harm humans, flora and fauna, lead to the formation of a greenhouse effect, thermal pollution and other negative phenomena. OM supplied to the market often do not meet the environmental requirements of regulatory documents; therefore, developments to reduce the negative impact on the environment are in demand. This article presents the results of measurements of the content of harmful emissions in the exhaust gases of the OM, the values of the level of nitrogen oxides (NOx) are at the upper limit of the permissible concentrations given in NSS and the Technical Regulations of the Customs Union [1, 2].

In addition to marine vessels with main engines up to 50 000 kW and mixed navigation vessels with main engines up to 2 000 kW, there are a huge number of small vessels in the world – motor boats and boats that make a significant contribution to environmental pollution, therefore, the assessment of harmful emissions and discharges, and most important – reducing the level of harmful emissions and discharges of engines of small vessels and OM, is a very urgent task considered by environmentalists around the world. Only for 2023, according to the State Inspectorate for Small Vessels (GIMS), there are more than 30 thousand motor water vehicles in the Astrakhan region.

Methods and means of improving the environmental performance of gasoline engines

Currently, to reduce emissions of nitrogen oxides (NOx), hydrocarbons (CH) and carbon monoxide (CO) in the exhaust gases of gasoline engines, catalysts are widely used that accelerate chemical reactions in the engine exhaust system, allowing to reduce the amount of harmful substances released into the atmosphere. Modern catalysts can be very effective, reducing emissions of harmful substances by 90% or more. There are also exhaust gas recirculation systems (EGR - Exhaust Gas Recirculation), which reduce the amount of nitrogen oxides released into the atmosphere by returning part of the exhaust gases back into the engine cylinders. But the idea arose not to fight the resulting negative fact, but to reduce its formation during the operation of the internal combustion engine by injecting water into the workflow, thereby reducing the fuel combustion temperature. But in this case, due to the fact that water is practically not compressed, there may be an increase in the compression ratio in the combustion chamber, which, according to the research of T. U. Asmus [3], can lead to the opposite effect, namely emissions of nitrogen oxides (NOx) and hydrocarbons (CH) increase. However, in defense of this method, A. L. Biryukov, justifies in his works the efficiency of using water as a fuel component for modern gasoline engines [4].

When water is supplied to the combustion chamber of the engine, it has a complex effect on the processes of mixing and combustion of fuel. The difference between the surface temperatures of the fuel and the boiling point of the water inside it (taking into account evaporation from the surface of the drop) is 70-200 °C, so the water begins to boil earlier than the fuel. Micro particles of water, passing into a vaporous state, form vapor bubbles. With gradual evaporation, the fuel film becomes thinner. There will come a moment when water vapor will destroy the surface of the drop, i.e. a micro-explosion will occur. With such a microburst, the drop is crushed, its particles intensively evaporate and mix, the process intensifies. The process of fuel combustion becomes more perfect. Attempts to supply water to the OM engine were made by domestic amateurs, but the goal was not to reduce the negative impact on the environment, but to increase the power of the OM [5].

By improving the mixing and combustion, as well as reducing the process temperature, the toxicity of exhaust gases is also significantly reduced. Water reduces the combustion temperature and the average cycle temperature, which mainly affects the kinetics of the formation of nitrogen oxides, and all chemical processes in general [6].

Description of the method of supplying water to the intake manifold of a four-stroke OM

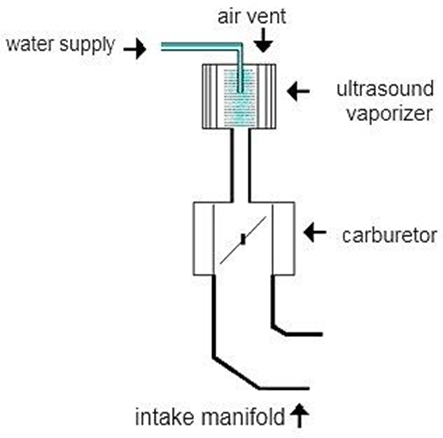

Existing water injection devices on the market in the internal combustion engine workflow have a number of disadvantages that prevent their integration into the OM. One of the main disadvantages is the weight and size dimensions, since an increase in weight and size is not acceptable for this type of small-size vessel engines. Also, based on the technical documentation provided in open sources, existing devices produce drops of a sufficiently large size, up to 0.1 mm. Based on the above, in the course of scientific work, the idea of supplying water to the intake manifold [7] in a finely dispersed phase produced by an ultrasonic atomizer was realized. Ultrasound nebulizer when supplying power and water from the cooling system of the OM under the influence of ultrasound leads to the formation of cavitation bubbles as a result of fluctuations of water molecules. During the experiments, the supply of water in the form of cold steam to the cylinder of the internal combustion engine of OM was carried out alternately in two ways, the first method: a built-in ultrasonic atomizer in the standard wiring and water cooling systems, the second method: cold steam supply to the suction manifold from an external source. During outdoor tests, the issue with the cooling of the OM was solved by supplying water to the cooling system of the internal combustion engine with a hose from the central water supply system through the slots in the bottom of the OM (Fig. 1) The main advantages of the selected device are the small mass-dimensional dimensions with high performance of drops and the relatively small size of the produced drops themselves from 0.005 to 0.001 mm., which create a fog-like cloud.

Fig. 1. Functional diagram of the ultrasonic

atomizer installation

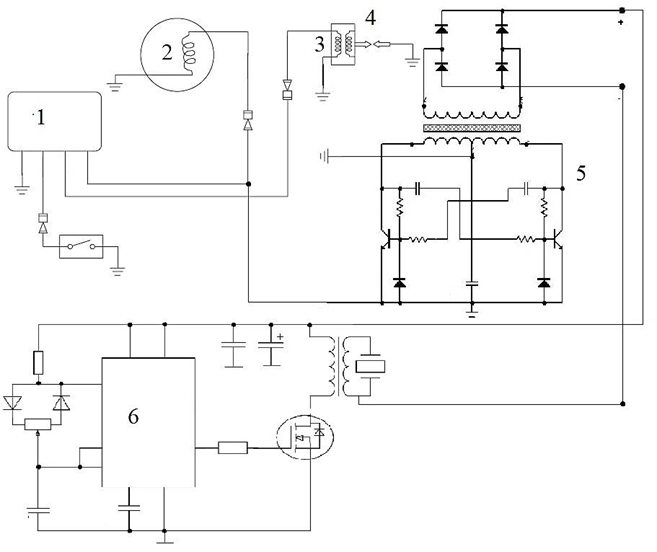

When power is supplied to the ultrasonic nebulizer from the standard OM power supply system (Fig. 2), water in a finely dispersed state is sprayed into the air intake, where it is suspended together with air. Next, the mixture of air and water is carried along the suction manifold where it is mixed with fuel and sucked into the cylinder of the internal combustion engine.

Fig. 2. Wiring diagram of the ultrasonic nebulizer to the standard OM power supply system: 1 – control unit;

2 – generator coil; 3 – ignition coil; 4 – spark plug; 5 – step-down current converter; 6 – ultrasonic nebulizer

In the process of filling (intake of fresh air charge), the engine takes air together with water and fuel. A finely dispersed mixture of water and air mixing with fuel enters the cylinder.

Instruments and equipment

1. Object of research: outboard outboard motor Yamaha F4BMHS 4 hp.

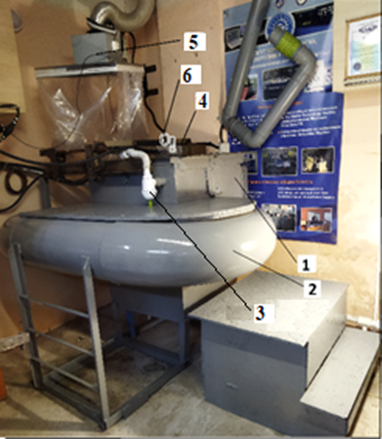

As an object of research, a four-stroke OM Yamaha F4BMHS 4 hp was used. The motors of this company are leaders in the world market. The type of outboard motor Yamaha F4BMHS 4 hp was installed in a small experimental with a water supply option from an external source is shown in Fig. 3.

The main technical characteristics of the outboard motor Yamaha F4BMHS 4 hp are given in Table 1.

Fig. 3. Outboard boat motor Yamaha F4BMHS 4 hp was installed in a small experimental pool

with a water supply option from an external source

Table 1

Main technical characteristics of the outboard motor Yamaha F4BMHS 4 hp

|

Parameter |

Value |

|

Power, hp (kW) |

4 (2.94) |

|

Type |

Four-stroke OHV S1 2 valves |

|

Number of cylinders |

1 |

|

Engine capacity, cc |

139 |

|

Cylinder diameter / Piston stroke, mm |

62 / 46 |

|

Max. number |

4 000-5 000 |

|

Engine lubrication system |

Crankcase |

|

Power supply system |

Carburetor |

|

Ignition system |

CDI |

|

Cooling system |

Water |

|

Exhaust gas exhaust system |

Through screw |

|

Weight, kg |

27 |

|

Deadwood length, mm |

381 |

2. Gas analyzer.

To measure the NOx content, the GANK-4 gas analyzer was used, Fig. 4, that has a certificate of verification.

The universal gas analyzer GANK-4 is an automatic measuring device is designed to measure the quantitative composition of the analyzed gas. It is structurally presented in a portable version.

The main elements of the design are:

– housing, depending on the modification, having a degree of protection from external conditions (IP);

– a primary converter that converts the gas concentration into a measured electrical signal using various measurement methods;

– a measuring and displaying module that processes the received signal in the set mode, comparing it with certain threshold values, storing processing and transmitting the result, including to a digital indicator;

– chem. cassette with a reactive tape;

– gas communication system for diffusion sampling, and for forced supply of the analyzed air using a built-in pump;

– clock control buttons of the gas analyzer.

The gas analyzer is designed to work in climatic conditions (Table 2).

Fig. 4. GANK-4 gas analyzer with a probe inserted

into the deadwood hole of the OM and a tachometer

sensor installed during testing in the open air

Table 2

Technical characteristics of the GANK 4 gas analyzer

|

Parameter |

Value |

|

The relative humidity of the surrounding air, % |

Is not more than 80 |

|

Ambient air temperature without the use of a thermostat, °С |

From plus 5 to plus 50 |

|

Ambient air temperature using a thermostat, °С |

From minus 50 to plus 5 |

|

Atmospheric pressure, kPa |

From 86 to 106.7 |

Ending of table 2

|

Parameter |

Value |

|

Metrological and technical characteristics |

|

|

Ranges of measurements of concentrations of harmful substances in atmospheric air |

From 0.5 MPC av.d. to 0.5 MPC w.a. |

|

Ranges of measurements of concentrations of harmful substances in the air of the working area |

From 0.5 MPC w.a. to 20 MPC w.a. |

|

Ranges of measurements of concentrations of harmful substances in vent discharges, industrial discharges and process gases |

More than 20 MPC w.a. with thinner putile solvent |

|

The temperature of the analyzed gas mixture at the gas analyzer inlet, °C |

From plus 5 to plus 50 |

|

Duration of sampling, s |

No more than 30 |

|

Limits of the basic relative measurement error, % |

±20 |

3. Small experimental pool of Astrakhan State Technical University (ASTU).

Also, for testing the characteristics of the OM, the stand Small experimental pool (hereinafter SEP) was used Fig. 5, built in the Federal State Educational Institution of Higher Education “ASTU” at the department “Operation of Water Transport and Industrial Fishing” in the scientific, educational and production laboratory “Outboard boat motors” [8].

a b

Fig. 5. General view of the small experimental pool: a – side view; b – top view: 1 – water tank; 2 – bypass pipe;

3 – siphon gas outlet; 4 – movable transom; 5 – exhaust ventilation; 6 – screw stop sensor; 7 – winch;

8 – supply ventilation; 9 – water level gauge, 10 – OM; 11 – sling; 12 – swivel boom

At the stand Small experimental pool it is possible to conduct complex tests of outboard boat motors with a capacity of up to 60 hp, with a screw stop of up to 200 kg. For installation on the stand of heavy motors weighing up to 160 kg, a rotary boom with a winch is provided; a siphon gas outlet and a discharge valve are provided for measuring harmful emissions and discharges in exhaust gases. The software TestMotor of a small experimental pool allows you to measure a number of parameters of an outboard motor, which include the power of an outboard motor, fuel consumption, the speed of rotation of the crankshaft, the speed of rotation of the propeller, the screw stop, the heating temperature of the outboard water. Tests at the Small experimental pool stand were carried out on the basis of NSS [9], close to the subject of development, according to the E4 cycle for spark-ignition engines on ships less than 24 m long.

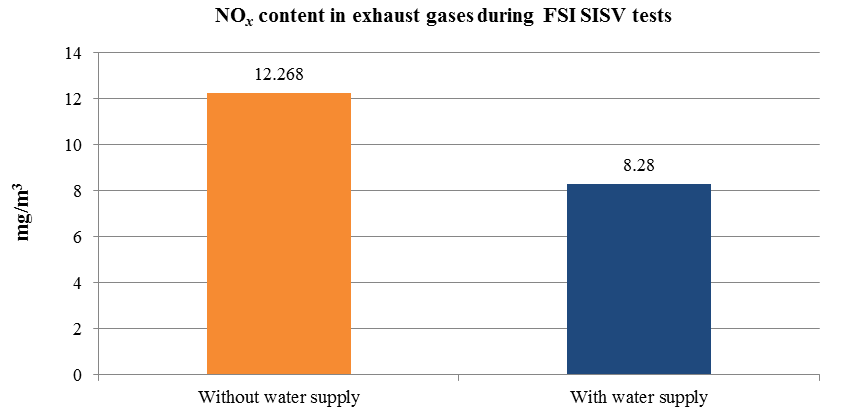

Progress and results of the study

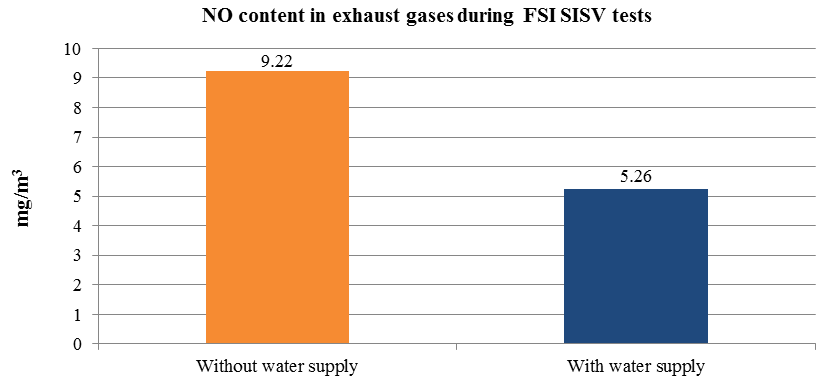

The study on the quantitative content of harmful emissions in the exhaust gases of the OM was carried out in accordance with the methodological recommendations on the procedure for the Federal State Institution by the State Inspectorate for Small Vessels (hereinafter referred to as the FSI SISV) The Ministry of Emergency Situations of Russia classifies small vessels in accordance with the technical regulations of the Customs Union On the safety of small vessels, approved by the Ministry of Emergency Situations of Russia on 26.09.2016, which prescribes to conduct a study in idle mode in the “neutral” position of the gearshift handle. Water injection into the intake manifold was carried out by an ultrasonic atomizer with a capacity of 0.08 ml/sec, that is, in one stroke the engine sucked 0.006 ml, with a specific fuel consumption of 0.3 liters/hour, the ratio of water to fuel was 1:1. During the experiment, no significant changes were observed in the quantitative content of CO and CH in harmful emissions, and the screw stop, exhaust gas temperature and fuel consumption practically did not change. But there was a significant decrease in nitrogen oxides NOx when water was injected into the suction manifold. The results of the experiment are shown in the diagram Fig. 6.

Fig. 6. NOx content in exhaust gases of the Yamaha F4BMHS 4 hp OM

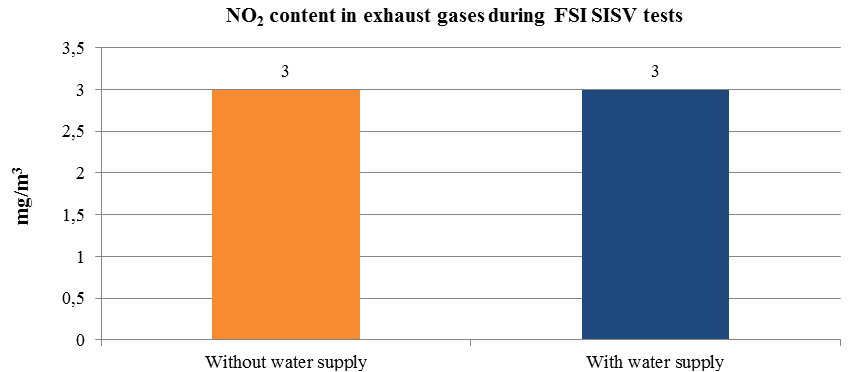

Taking into account the capabilities of the GANK-4 device, the results of the quantitative content in the exhaust gases were decomposed into components, as a result, the results of the content of nitrogen oxides NO and NO2 were obtained separately (Fig. 7, 8).

Fig. 7. NO content in exhaust gases of Yamaha F4BMHS 4 hp OM

Fig. 8. NO2 content in exhaust gases of Yamaha F4BMHS 4 hp OM

As can be seen from the figure, nitric oxide (NO) decreases by 43% when water is supplied to the intake manifold of the OM, reducing the total amount of nitric oxide (NO) in the exhaust gases by 3.96 mg/m3.

The experiment showed that the injection of water into the OM cylinder does not affect on the formation of nitrogen dioxide (NO2) in any way and the quantitative composition remained at the same level.

Conclusion

The novelty of this study is the use of an ultrasonic atomizer to supply water to the cylinder of the internal combustion engine of the OM. The main advantages of the ultrasonic nebulizer are small mass-dimensional dimensions with high productivity of drops measuring 0.005 to 0.001 mm, which create a fog-like cloud. Existing devices on the market do not allow to spray water to a similar size of drops, besides these devices have a large weight and size, which makes them impossible to integrate into the OM.

After analyzing the data obtained during additional experiments on various operating modes of the OM, it was found that the water supply does not affect such characteristics of the motor as the screw stop and fuel consumption. According to the presented diagrams, it is possible to observe a reduction in harmful emissions in the NOx part by 32.5%. Moreover, when decomposing into NOx components, it can be concluded that a decrease in the amount of NOx. It occurs due to a decrease in NO by 43%, while the value of NO2 did not change during a number of experiments. The reduction of harmful emissions in the NO part was positively due to the cooling of burning temperature, since water has a high heat capacity and is able to take heat during the interaction. Based on these results, it is clear that this method is aimed only at combating the content of NO. Given the chemical activity of NO2, an alkaline component should presumably be introduced into the fuel combustion process, which can form nitrates and nitrites.

1. ГОСТ 28556-2016. Моторы лодочные подвесные. Общие требования безопасности. М.: Стандартинформ, 2016. 5 с.

2. ТР ТС 026/2012. О безопасности маломерных су-дов: технический регламент таможенного союза. URL: https://docs.cntd.ru/document/902352820?sclid=lofh347j9x362692126. (дата обращения: 07.12.2022)

3. Асмус Т. У., Боргнакке С., Кларк К. и др. Топ-ливная экономичность автомобилей с бензиновыми дви-гателями / пер. с англ. А. М. Васильева. М.: Машино-строение, 1988. 504 с.

4. Бирюков А. Л., Коптяев В. А. Обоснование эф-фективности использования воды в качестве компонента топлива для современных бензиновых двигателей // Наука - производству: сб. тр. Междунар. науч.-практ. конф., посвящ. 95-летию акад. Вологда - Молочное: Изд-во ВГМХА, 2006. Т. 2. C. 10-13.

5. Впрыск воды в ПЛМ «Вихрь». URL: http://www.barque.ru/engine/1982/water_injection_into_the_carburetors (дата обращения: 07.12.2022).

6. Бирюков А. Л., Коптяев В. А. Методика и неко-торые результаты исследований показателей работы бензинового двигателя с распределенным впрыском при использовании в качестве топлива бензоводяной смеси // Наука - технология - ресурсосбережение: материалы II Всероссийской науч.-практ. конф. СПб.; Киров: Изд-во Рос. акад. трансп.; ВГСХА, 2008. C. 43-46.

7. Бирюков А. Л., Коптяев В. А., Ножнин С. Р. Спо-соб и устройство для получения и подачи воды совместно с топливом во впускной трубопровод ДВС // Аграрная наука - сельскохозяйственному производству: сб. тр. Науч.-практ. конф., посвящ. 97-летию акад. Вологда - Молочное: Изд-во ВГМХА, 2008. C. 143-146.

8. Покусаев М. Н., Хмельницкий К. Е., Хмельниц-кая А. А., Руденко М. Ф., Кадин А. А., Клочкова Г. Г. Изменение конструкции малого опытового бассейна для комплексных испытаний подвесных лодочных моторов // Вестн. Астрахан. гос. техн. ун-та. Сер.: Морская техника и технология. 2022. № 4. C. 19-26. https://doi.org/10.24143/2073-1574-2022-4-19-26. EDN ARGWHP.

9. ГОСТ 30574-98. Измерение выбросов вредных ве-ществ с отработавшими газами. Циклы испытаний. Минск: Изд-во стандартов, 1999. 89 c.