Россия

Россия

Россия

Россия

УДК 656.6 Эксплуатация водного транспорта

Рассматриваются условия возможных путей совершенствования транспортно-логистического обеспечения промысловой деятельности. Описана организация работы рыбопромыслового флота в рыбопромысловой экспедиции. Сформулирована общая схема функционирования системы доставки рыбопродукции из района промысла конечному потребителю с учетом ее структуры и требований подразделений данной системы друг к другу. На основе детального анализа с учетом стратегии развития рыбной отрасли и перспектив доставки рыбопродукции потребителям по Северному морскому пути сформулированы и описаны уточненные требования к проектируемой организации работы флота в традиционном и альтернативном логистическом ключе. В поисках возможных путей оптимизации системы транспортно-логистического обеспечения промысла были рассмотрены примеры варианта работы приемно-транспортных судов при организации обслуживания промысла по схеме «район промысла – промысловая флотилия – плавбаза – транспортный флот – порт-«хаб» – транспортный флот – порт». Использован системный подход с применением метода линейного программирования. Для решения задачи транспортного обслуживания районов промысла была разработана математическая модель на основе распределительной задачи линейного программирования по расстановке транспортных судов на «плечах» доставки рыбопродукции в порты перегруза. В математической модели задачи используется два типа переменных, в качестве целевой функции рассматриваются суммарные расходы на перевозку рыбопродукции, которые должны быть минимизированы с учетом ряда ограничений. На основании результатов предварительных расчетов для решения поставленной задачи в соответствии с математической моделью была использована надстройка «Поиск решения» программы MS EXCEL. Результаты моделирования позволили сформулировать логистическую составляющую обслуживания районов промысла и обосновать преимущества данного подхода для оптимизации выбора портов-кластеров, а также выбора транспортных судов и их расстановки по маршрутам перевозки рыбопродукции потребителю с наименьшими затратами.

рыбопромысловая экспедиция, транспортный рефрижератор, плавбаза, оптимальный вариант, порты-кластеры, линейное программирование, распределительная задача, целевая функция, ограничения, переменные, математическая модель, рейс транспортного судна

Introduction

The logistics supply chain of fish products from the fishing areas to the main points of consumption has always been one of the most important issues in the fisheries industry. The organization of the export of fish products from fishing areas and the supply of mining vessels is a rather complex, but mandatory process requiring a specialized logistical approach [1].

The Far Eastern fisheries basin accounts for 2/3 of the total catch of Russian fishermen. It is with this region that the main potential for the growth of fish products supplies to the domestic market of the Russian Federation is associated, in the long term until 2030 it can provide at least 400-500 thousand tons of fish products in addition [2].

The demand from fishermen, sellers and buyers for the transportation of fish and marine products with temperature control continues to grow both during import and export, as well as domestic transportation. In this regard, new logistics routes are opening up for Russian fish products, including opportunities to optimize the maintenance of fishing areas. In such a situation, structured logistics and, above all, transportation are especially important – optimization of traditional methods of delivering fish products to consumers.

Thus, the updated concept of the development of the fisheries industry until 2030 provides for a large-scale change in the structure of production towards deep and waste-free processing, an increase in catch due to new fishing facilities. According to the strategy, the fishing terminals of Primorsky Krai will take the main load of the additional commodity flow. Whole complexes will be created at individual enterprises – fish clusters, which include, in addition to cold storage, processing and auction trading. Cargo turnover through the ports of Primorsky Krai may increase by more than 1.5 times by 2025 [2].

The relevance of the chosen topic of this article is primarily due to the need to improve the transport system for the distribution and delivery of fish products from the fishing site to the ports of the Russian Federation by improving the transport system for distribution and delivery.

Materials and methods

When organizing the work of a fishing fleet, the concept of a fishing expedition is used – the organization of fishing by object or fishing area. The organization of the fishing facility is carried out in relation to fish bioresources that have the property of commercial availability at certain times of the year, which in turn allows them to be seized on an industrial scale in one fishing zone. In turn, the organization of the fishing area involves the formation of a group of fishing vessels that catch fish in several fishing zones at the same time [3]. In this study, a comparative analysis is performed in relation to the integrated organization of the fleet (mining, processing and transport) by fishing areas.

The general scheme of operation of the fish products delivery system from the fishing area to the consumer consists in determining the structure of its technical and material means, first formulating the enlarged, most significant requirements of the structural units of this system to each other and to the system as a whole. Based on a detailed analysis, specific requirements for the projected fleet management organization are formulated.

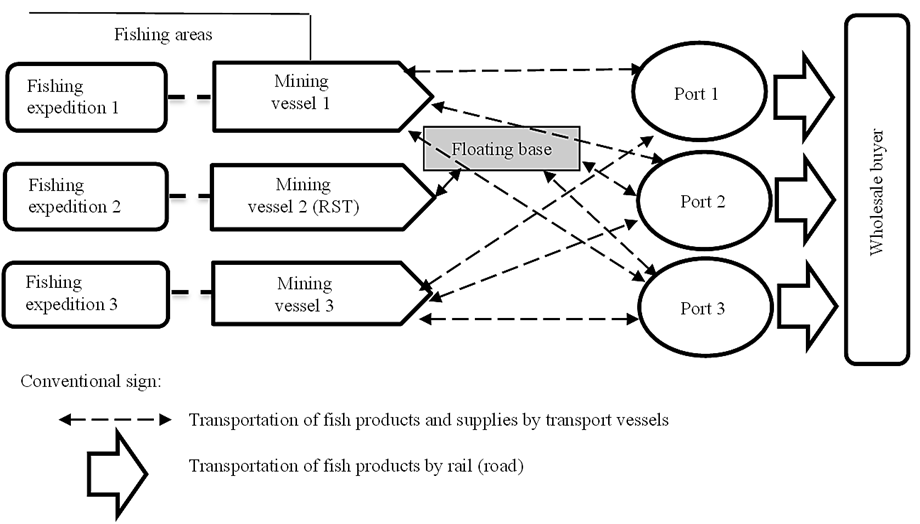

The structure of the traditional fish product distribution system “fishing area – fishing fleet – transport fleet – fishing ports – railway (automobile) transport – wholesale buyers” is shown in Fig. 1.

Fig. 1. Traditional logistics scheme for delivering fish products to the consumer

Currently, in accordance with the concept of the development of the fisheries industry until 2030, it is planned to change the logistical structure of fish production due to waste-free processing, increased catch, as well as the development of the domestic market through the creation of alternative schemes for the delivery of products and modernization of port infrastructure.

According to the strategy, fishing terminals located in proximity to the main fishing areas should act as “hubs” for the distribution of additional commodity flow. For example, Magadan Port has a unique position: about 200 thousand tons of fish are produced in the northern and central part of the Sea of Okhotsk, as well as 200 thousand tons of salmon per year.

This is due to the long downtime of ships waiting for cargo transshipment or their control in Vladivostok Port. The average duration of downtime is from two to five days, which leads to the loss of 47.6 thousand ship hours per year and economic losses in the amount of 3.8 billion rubles.

According to the concept, fish and fish products are delivered to Magadan Port, reloaded into a refrigerated container on the principle of a container ship and then sent to the recipient by road along the Kolyma highway, by sea to the port of Vladivostok or along the Northern Sea Route, as well as directly to the countries of the Asia-Pacific region. The volume of transshipment is 200-220 thousand tons per year. The port will be able to serve vessels of various types, including vessels with a draft of up to 10 meters and a gross capacity of up to 10 thousand tons. The terminal for integrated ship maintenance in Magadan will include unloading of products, parking, bunkering, inter-voyage maintenance, crew change, and restocking. The passage of a vessel from the main fishing areas to the most popular port of Vladivostok in summer takes at least six days, and the journey to the port of Magadan will take one or two days. At the same time, the cost of transferring to Primorye per vessel is estimated at 100 thousand US dollars. In the period from September to May, about 50 vessels are employed in the pollock fishery [4]. The port of Magadan has a huge advantage – the presence of a deep-water bay, which allows not only to receive heavy-duty vessels with the further possibility of transshipment of fish products into refrigerated containers, but also allows in the future an increase in the size of berths with a length of at least 100 meters. Consumers tend to choose higher-quality fish products, and a refrigerated container is the easiest and most reliable way to deliver it over long distances in the most preserved form.

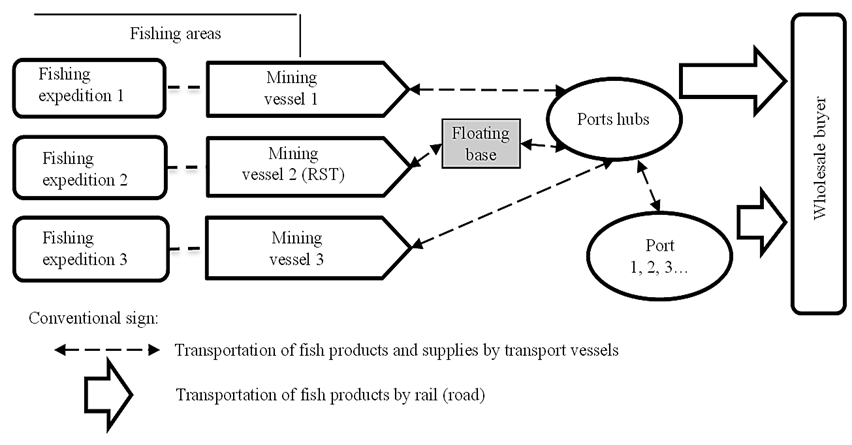

In accordance with the implementation of the concept of creating fishing clusters based on existing fish terminals, it is necessary to develop an alternative logistics scheme for the delivery of fish products to consumers. An alternative structure of the fish product delivery system “fishing area – fishing flotilla – transport fleet – port hub – transport fleet (rail (road) transport) – wholesale buyer” is shown in Fig. 2.

Fig. 2. Alternative logistics scheme for delivering fish products to the consumer

The organization of the proposed logistics option for the delivery of fish products to the consumer includes:

– the traditional method of delivery, but taking into account the possibility of effective placement of transport vessels both on “short shoulder” (fishing area – port-“hub”) and on the shoulder (port-“hub” – port of unloading), in addition, it allows for the transshipment of cargo into containers and the use of heavy-duty vessels;

– an alternative option involves coordinating the technological process of delivering fish products to the consumer, taking into account the possibility of using container technologies and related modes of transport.

Setting the task

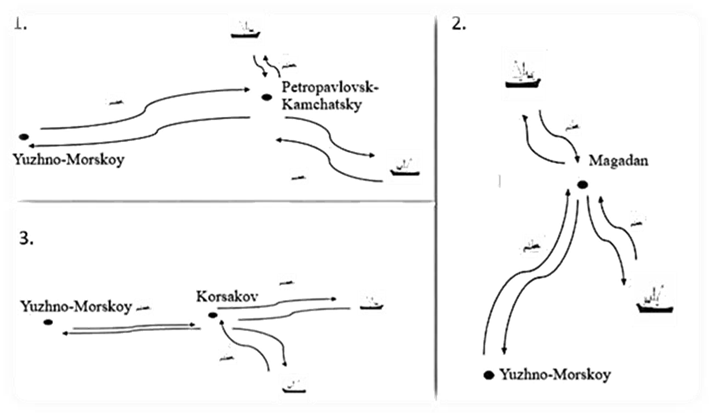

In search of possible ways to optimize the system of transport and logistics support for fishing, examples of the operation of transport vessels with an alternative method of organizing fishing services according to the scheme “fishing area – fishing flotilla (RST) – floating base – transport fleet – port-“hub” – transport fleet – port” were considered (Fig. 3).

Fig. 3. Transport and logistics scheme for the operation of transport vessels with

an alternative method of organizing fishing services

The linear programming method is used to determine the optimal route for the organization of transport and logistics support for the fishery. The solution of the problem is realized by the compiled mathematical model of the problem and the algorithm developed by the authors in the “Solution search” MS Excel.

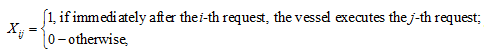

The mathematical model of a distributive problem consists of variables, objective functions, and a system of constraints. We use two groups of variables – Xij, Yi:

Yi – the start time of the i-th application (the time of arrival of the vessel for loading according to the i-th application).

The objective function of the task should ensure the minimum total costs for the operation of ships:

Z = qxBTåiåjxijtij + Tokсpåjxj + åjtjqxBT ® min,

where qx – fuel consumption on the move, t/d; ВТ – the price of heavy fuel, Rub./t; tij – the duration of the transition from the place of unloading according to the i-th application to the place of loading according to the j-th application, d; To – operational period, d; kсp – the cost of maintaining the vessel in the parking lot, Rub./d; tj – is the travel time of vessels when fulfilling requests, d.

It is also necessary to introduce a system of restrictions, which will provide for the fulfillment of a number of conditions:

yi + τi + tij – M(1 – xij) £ yj("j), (1)

where is τi – the duration of the i-th application; M – is an arbitrary large positive number (assumed to be 100 000);

åiXij = 1("j, except j = ); (2)

åiXij = åJXij ("j, i); (3)

yi ³ ai ("j, except i = 0), (4)

where is ai – the earliest time for the start of loading according to the i-th application;

yi £ bi ("j, except i = 0), (5)

where is bi – the latest time for the start of loading according to the i-th application;

yi ³ 0. (6)

Restriction (1) provides that if the j-th application is executed immediately after the i-th application, then the start time of the j-th application must be greater than or equal to the end time of the previous i-th application plus the duration of the transition to the place of loading according to the j-th application. Restriction (2) stipulates that one vessel must fulfill each request. Restriction (3) ensures the coherence of the work plan of the courts. Restriction (4) stipulates that the vessel must start fulfilling the request no earlier than the stipulated time. Restriction (5) stipulates that the vessel must start fulfilling the request no later than the stipulated time. Constraint (6) introduces the condition of non-negativity of the variable yi.

The results of the study

As initial data for solving the problem, the following are used:

– data on the technical and operational characteristics of standard transport vessels operating in the directions of Okhotomorskaya (OME), Yuzhnokurilskaya (SKE) Sakhalin and Bering Sea (BME) fishing expeditions [5];

– characteristics of cargo spaces of transport vessels;

– applications for fish collection and transfer of supplies to floating bases. The calculations used data from applications for the operation of two types of floating bases: KE – 1 type and VS – 2 type;

– the total voyage time of the transport vessel in days (the duration of the transition from the port to the fishing zone and the duration of the parking time);

– data on the operating costs of the transport vessel for one voyage (thousand rubles).

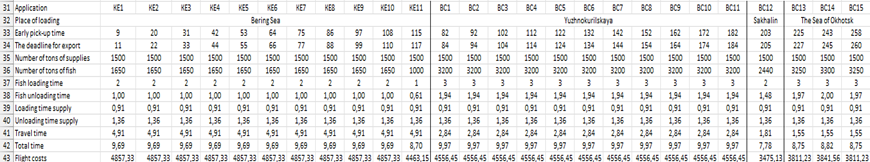

The appearance of the MS Office Excel worksheet with initial data for solving the transport problem with integer variables is shown in Fig. 4.

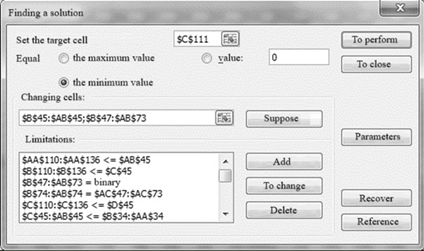

The appearance of the dialog box of the “solution search” wizard is shown in Fig. 5.

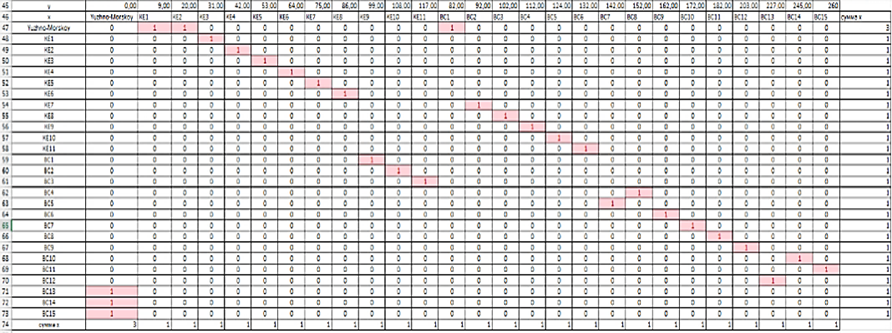

An example of the result of solving the distribution problem according to the option “Fishing zones – Magadan Port – South Sea Port” is shown in Fig. 6.

Fig. 4. Example of order parameters

Fig. 5. Dialog window of the “Search for a solution” wizard with restrictions

Fig. 6. An example of solving the distribution problem “Fishing zones – Magadan Port – South Sea Port”

Fig. 6 shows that in order to carry out transport and logistics support in the direction of fishing zones − Magadan port (“hub”), 3 transport refrigerators (sum x) will be needed, which will ensure the full volume of supply and export of fish products [6] (according to the schedule of the floating base in the fishery for 260 days):

– transport vessel 1 operates according to the requests of floating base KE (1st cargo operations) for 9 days; floating base KE (3rd cargo operations) for 31 days; floating base KE (5th cargo operations) for 53 days; floating base KE (7th cargo operations) for 75 days; floating base VS (2nd cargo operations) for 92 days; floating base KE (10th cargo operations) for 108 days; floating base VS (5th cargo operations) for 124 days; floating base VS (7th cargo operations) for 142 days; floating base VS (10th cargo operations) for 172 days; floating base VS (14th cargo operations) for 245 days;

– transport vessel 2 works on request: floating base KE (2nd cargo operations) for 20 days; floating base KE (4th cargo operations) for 42 days; floating base KE (6th cargo operations) for 64 days; floating base KE (8th cargo operations) for 86 days; floating base VS (3rd cargo operations) for 102 day; floating base KE (11th cargo operations) for 117 days; floating base of the VS (6th cargo operations) for 132 days; floating base of the VS (9th cargo operations) for 162 days; floating base of the VS (12th cargo operations) for 203 days; floating base of the VS (13th cargo operations) for 227 day;

– transport vessel 3 operates according to the requests of floating base VS (1st cargo operations) for 82 days; KE floating base (9th cargo operations) for 99 days; floating base VS (4th cargo operations) for 112 days; floating base VS (8th cargo operations) for 152 days; floating base VS (11th cargo operations) for 182 days; afloat base (15th cargo operations) for 260 days.

Discussion

The analysis of modeling options for the operation of transport vessels servicing Okhotomorskaya (OME), Yuzhnokurilskaya (SKE), Sakhalin and Bering Sea (BME) fishing expeditions showed:

1. In the case of transshipment in Magadan Port, 3 transport vessels are required to work on the shoulder of “fishing area – Magadan Port”. When transporting from Magadan Port to South Sea Port, 2 transport vessels will be required. The total amount of transportation costs is 662.8 million rubles.

2. With the option of transshipment in the port of Korsakov Port, 3 transport vessels are needed to work on the shoulder of “fishing area – Korsakov Port”. When transporting from Korsakov Port to South Sea Port, 1 transport vessel will be needed [6]. The total amount of transportation costs will amount to 640.9 million rubles.

3. With the option of transshipment in Petropavlovsk-Kamchatsky Port, 3 transport vessels are required to work on the shoulder of “fishing area – port of Petropavlovsk-Kamchatsky Port”. When transporting from Petropavlovsk-Kamchatsky to South Sea Port, 2 trans-port vessels will be required. The total amount of transportation costs will amount to 639.1 million rubles, which is optimal compared to other options.

Conclusion

In search of possible ways to improve the transport and logistics support of fishing, the study considered the issue of modeling the operation of transport vessels, taking into account the implementation of the concept of creating fishing management clusters based on existing fish terminals and the development of an alternative logistics scheme for the supply of fish products to consumers. To solve the problem of optimizing the transportation service system of the fishing area, a systematic approach was used using the linear programming method, which will allow:

– coordinate the technological process of delivering fish products to the consumer, taking into account the possibility of using container technologies and related modes of transport;

– to select the optimal cluster port for transshipment of fish products and develop a logistics scheme for the delivery of fish products to consumers;

– to select the types of transport vessels and their number and arrangement in the directions of transport and logistics chains for the transportation of fish products to consumers and the supply of fisheries.

1. Вальков В. Е. Анализ проблем комплексного обслуживания рыболовного флота Российской Федерации // Вестн. Астрахан. гос. техн. ун-та. Сер.: Морская техника и технология. 2024. № 3. С. 7–16. https://doi.org/10.24143/2073-1574-2024-3-7-16.

2. На площадке «РЖД» обсудили организацию транспортировки рыбопродукции с Дальнего Востока в центральные регионы. URL: https://www.fishnet.ru/news/rynok/na-ploschadke-quot-rzhd-quot-obsudili-organizaciyu-transportirovki-ryboprodukcii-s-dalnego-vostoka-v-centralnye-regiony/ (дата обращения: 19.08.2024).

3. Лисиенко С. В., Вальков В. Е., Иванко Н. С., Бойцов А. Н. Разработка математической модели и оптимизационной задачи по организации и управлению промысловым флотом при ведении добычи водных биологических ресурсов на примере промысла дальневосточной сардины (иваси) и скумбрии в Дальневосточном рыбохозяйственном бассейне // Мор. интеллектуал. технологии. 2019. № 4-2 (46). С. 147–153.

4. Магадан возрождает промысел. URL: https://www.kommersant.ru/doc/6268735 (дата обращения: 28.08.2024).

5. Антонова Е. И., Вольнов И. Н. Экономико-мате-матический анализ процесса взаимодействия рыбопромысловых и транспортных судов в районах промысла // Эксплуатация мор. трансп. 2021. № 3 (100). С. 3–11. DOI:https://doi.org/10.34046/aumsuomt100/1.

6. Юденкова Л. И., Валькова С. С., Вальков В. Е. Управление работой флота. Оперативно-технический план работы рыбопромысловых флотилий: учеб. пособие. Владивосток: Изд-во Дальрыбвтуза, 2022. 92 с.