Россия

Россия

Рассматриваются возможности повышения энергоэффективности в судостроительной и судоремонтной отрасли. Энергоэффективность играет ключевую роль в современной промышленности, особенно в отраслях с высоким уровнем энергопотребления, таких как судостроение и судоремонт. В Астраханской области при значительном количестве имеющихся водных ресурсов находится множество предприятий указанной отрасли. Представлен обзор отрасли в регионе, проведен анализ структуры и динамики электропотребления на предприятиях данной отрасли, идентификация основных потребителей электроэнергии и выявлены наиболее энергозатратные процессы. На основе этих данных предлагаются меры по оптимизации энергопотребления. Проанализированы существующие технологии и методы, направленные на снижение энергозатрат и повышение энергоэффективности в судостроительной и судоремонтной отрасли. Рассматриваются как технические, так и организационные меры, такие как внедрение энергосберегающего оборудования, оптимизация производственных процессов и внедрение систем мониторинга и управления энергопотреблением. Рекомендации по повышению энергоэффективности предприятий судостроительной и судоремонтной отрасли позволят снизить затраты на энергию, улучшить экологическую устойчивость производства и повысить конкурентоспособность компаний в условиях рыночной экономики. Полученные результаты могут быть использованы руководством предприятий, специалистами по энергоменеджменту и государственными органами для разработки стратегий по сокращению энергопотребления и улучшению энергоэффективности в данной отрасли. Комплексный подход будет полезен предприятиям судостроительной и судоремонтной отрасли для эффективного использования имеющихся ресурсов, сокращения издержек и минимизирования отрицательного воздействия на окружающую среду, что в долгосрочной перспективе поспособствует увеличению конкурентоспособности и устойчивости.

повышение энергоэффективности, электропотребление предприятий, факторы энергоэффективности, предприятия Астраханской области, судостроительная и судоремонтная отрасль

Introduction

The ship repair and shipbuilding industry plays a key role in the economic development of the regions [1], providing support and development of marine and river transport communications. The Astrakhan region, having significant water resources and an advantageous geographical location, is important for the development of water transport, shipbuilding and ship repair. In modern conditions, when the region is faced with increasing competition in the markets, it is important to actively consider and optimize energy consumption at enterprises. In this context, understanding and optimizing energy consumption at enterprises is becoming an important element of the strategy for sustainable development of both enterprises themselves and the economy of the region. Power consumption in the ship repair industry is of strategic importance, as it has a direct impact on the operating costs of enterprises, their competitiveness, as well as environmental sustainability. Federal Law No. 261 [2] and the State Program “Development of Shipbuilding 2013-2030” [3] emphasize the relevance of the analysis and assessment of energy consumption at enterprises of the ship repair and shipbuilding industry for the analysis and accounting of energy efficiency.

The purpose of this article is to analyze and statistically evaluate the power consumption of enterprises in the shipbuilding and ship repair industry of the Astrakhan region. The study will review the ship repair industry in the region, analyze energy consumption at enterprises, and identify the main factors affecting energy efficiency and prospects for improvement in this area.

The study of electricity consumption in the shipbuilding and ship repair industry of the Astrakhan region is of practical importance: the analysis allows you to identify reserves to reduce operating costs and increase the competitiveness of enterprises; energy efficiency assessment helps to minimize the negative impact on the environment; the results of the study can serve as a basis for the development of strategies and programs to improve energy efficiency and sustainable development of the ship repair industry in the region.

Research objectives:

1. To review the industry in the Astrakhan region.

2. Collect and analyze data on electricity consumption at enterprises in the region in order to identify trends.

3. Identify the key factors affecting the energy efficiency of ship repair enterprises in the Astrakhan region.

4. Assess the current level of energy efficiency and identify potential areas for improvement.

General characteristics of the ship repair industry in the region

A general overview of the ship repair industry in the Astrakhan region highlights its importance for the regional economy and transport infrastructure, and also points to the need to analyze and optimize energy consumption in order to increase the efficiency and competitiveness of enterprises in this industry.

The shipbuilding and ship repair industry in the Astrakhan region plays an important role in the development of sea and river transportation, providing maintenance and repair of watercraft. Shipbuilding enterprises build bulk carriers, tankers, passenger and auxiliary fleet vessels, and crane vessels. Large enterprises of the shipbuilding complex of the Astrakhan region specialize in the construction of offshore hydraulic structures for the development of offshore fields. The total metal processing capacity of shipbuilding and ship repair enterprises of the Astrakhan region is up to 90 thousand tons per year [4]. The region is located at the intersection of many important transport routes, including the Volga Reservoir and the Caspian Sea, which gives special strategic importance to ship repair activities in this area.

For many years, shipbuilding enterprises of the Astrakhan region have been regularly fulfilling orders from partners from the Caspian states for the construction of large and technically complex marine engineering structures designed for the search and production of hydrocarbons in offshore fields, and the repair of vessels of various classes and purposes [5].

Astrakhan region has vast water areas, including the Caspian Sea and the Volga River. The presence of ship repair facilities near important transport routes ensures the convenience and accessibility of ship maintenance.

The shipbuilding industry in the region has a long history and has gone through a number of stages of development [1].

Ship repair companies make a significant contribution to the economy of the region, providing jobs for the local population and attracting investment in development. In addition, ship repair works are an integral part of the maintenance of marine and river vessels, which contributes to the development of the transport infrastructure of the region.

In recent years, the industry in the Astrakhan region has been actively introducing new technologies and working methods aimed at improving the efficiency and quality of repair work. This includes the automation of processes, the use of modern equipment and materials, as well as the introduction of digital technologies in production management.

General information on electricity consumption at enterprises of the shipbuilding and ship repair industry

An overview of the main energy consumption facilities at ship repair enterprises.

Electrical consumption at ship repair enterprises can be significant, since a variety of equipment for ship repair, maintenance and construction is widely used in this industry.

Power tools and equipment: industry enterprises use various power tools, such as electric drills, grinders, grinders, etc.

Welding equipment: welding work requires significant energy consumption.

Electric drive mechanisms: a variety of electric drive mechanisms such as electric winches, cranes, conveyors and other systems for moving and lifting various loads and equipment.

Air conditioning and lighting systems: climate systems, lighting and heating devices are also objects of electrical consumption in enterprises, ensuring working conditions and maintaining optimal indoor temperature.

Electrical systems of ships: the ship is powered from the shore during repair or construction.

To determine the main consumers of electric energy, the authors studied data on the power of consumers at a large enterprise, which are presented in Table 1.

Table 1

Power of consumers

|

Consumer |

Power, kW |

|

Ship building workshop |

1 200 |

|

Welding shop |

900 |

|

Pumping station |

200 |

|

Foundry |

800 |

|

Internal combustion engine repair shop |

550 |

|

Floating dock |

1 600 |

|

Mechanical workshop |

1 740 |

|

Compressor room |

600 |

|

Warehouse |

350 |

|

Office |

750 |

|

The main building |

1 700 |

|

Lighting of workshops and territory |

350 |

Based on these data, the maximum power consumption falls on the hull shop, floating dock, and machine shop.

Having studied and analyzed the equipment, the following main consumers of electric energy have been identified. The most powerful consumers are listed below in descending order of power consumption:

1. Electric furnaces;

2. Electric welding;

3. Universal machines;

4. Specialized, aggregate machines;

5. Lighting of workshops and territory;

6. Fans;

7. Cranes, girder cranes, lifting mechanisms.

Analysis of power consumption.

Several companies have been selected for the analysis. According to the average number of employees, enterprises are divided into categories [6]. So, there are microenterprises – up to 15 people, a small enterprise from 16 to 100 people, a medium-sized enterprise – from 101 to 250 people. With a larger number, the company is large. One company was selected, except for microenterprises. Based on the data provided by authorized persons, namely those responsible for the electrical facilities at the enterprises, an analysis will be carried out. At the request of the owners, the names of the enterprises are not indicated.

All enterprises have certificates of recognition of the Russian Maritime Register of Shipping and the Russian Classification Society.

The types of activities include:

1. Defection and repair of ship hulls, mechanisms, systems, devices, pipelines, boilers, pressure vessels, electrical equipment of ships and floating objects;

2. Overhaul of marine internal combustion engines;

3. Development of working documentation;

4. Construction of vessels of various lengths and dock weights depending on the size of the enterprise;

5. Non-destructive testing methods; etc.

The tables below show power consumption data for 2022-2023.

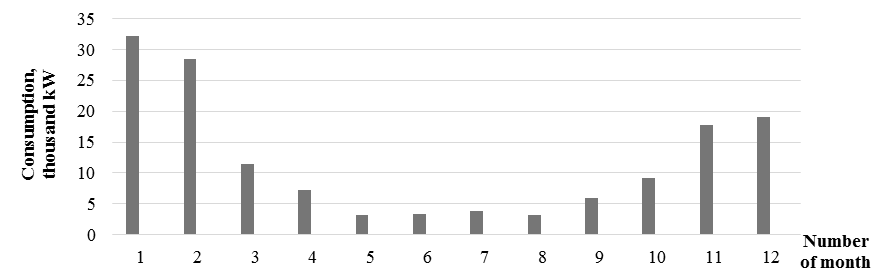

Table 2 shows data on electricity consumption by month of a small enterprise with 28 employees.

Table 2

Power consumption of a small enterprise

|

Month/year |

Consumption, thousand kW |

|

January 2022 |

30,2 |

|

February 2022 |

31,3 |

|

March 2022 |

10,5 |

|

April 2022 |

6,8 |

|

May 2022 |

3,1 |

|

June 2022 |

3,1 |

|

July 2022 |

3,2 |

|

August 2022 |

3,6 |

|

September 2022 |

6,5 |

|

October 2022 |

9,1 |

|

November 2022 |

18,2 |

|

December 2022 |

20,7 |

|

January 2023 |

32,2 |

|

February 2023 |

28,4 |

|

March 2023 |

11,5 |

|

April 2023 |

7,3 |

|

May 2023 |

3,2 |

|

June 2023 |

3,4 |

|

July 2023 |

3,9 |

|

August 2023 |

3,2 |

|

September 2023 |

6,0 |

|

October 2023 |

9,2 |

|

November 2023 |

17,8 |

|

December 2023 |

19,1 |

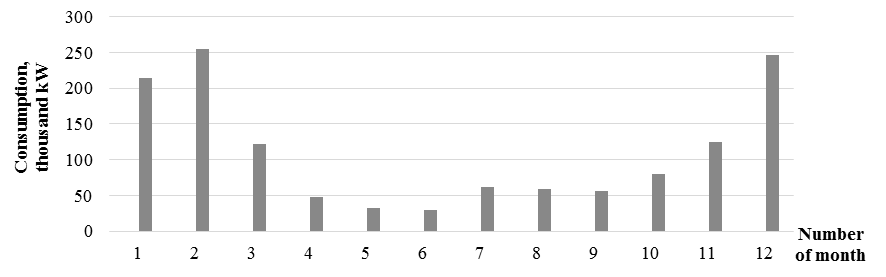

Table 3 shows data on electricity consumption by month of an average enterprise with 123 employees.

Table 4 shows data on electricity consumption by month of a large enterprise with 600 employees.

Studying the data from other years, the difference in consumption relative to the presented data is small and is within 10%, which allows you to track trends according to the values presented above.

Figure show diagrams of the distribution of electricity consumption by month of 2023 at enterprises.

Table 3

Power consumption of an average enterprise

|

Month/year |

Consumption, thousand kW |

|

January 2022 |

224,5 |

|

February 2022 |

234,8 |

|

March 2022 |

121,6 |

|

April 2022 |

45,5 |

|

May 2022 |

33,3 |

|

June 2022 |

28,1 |

|

July 2022 |

58,8 |

|

August 2022 |

60,5 |

|

September 2022 |

54,4 |

|

October 2022 |

79,2 |

|

November 2022 |

125,7 |

|

December 2022 |

250,1 |

|

January 2023 |

214,5 |

|

February 2023 |

254,4 |

|

March 2023 |

122,5 |

|

April 2023 |

47,3 |

|

May 2023 |

32 |

|

June 2023 |

30,1 |

|

July 2023 |

61,8 |

|

August 2023 |

59,6 |

|

September 2023 |

56,7 |

|

October 2023 |

79,7 |

|

November 2023 |

124,8 |

|

December 2023 |

247,1 |

Table 4

Power consumption of a large enterprise

|

Month/year |

Consumption, thousand kW |

|

January 2022 |

1117 |

|

February 2022 |

848,4 |

|

March 2022 |

592,4 |

|

April 2022 |

336,2 |

|

May 2022 |

231,4 |

|

June 2022 |

253,4 |

|

July 2022 |

188,1 |

|

August 2022 |

250,2 |

|

September 2022 |

310,7 |

|

October 2022 |

462,1 |

|

November 2022 |

762,3 |

|

December 2022 |

1 058,6 |

|

January 2023 |

1 111,5 |

|

February 2023 |

846,4 |

|

March 2023 |

594 |

|

April 2023 |

339,2 |

|

May 2023 |

234,4 |

|

June 2023 |

253,1 |

|

July 2023 |

187,1 |

|

August 2023 |

255,6 |

|

September 2023 |

311,7 |

|

October 2023 |

467 |

|

November 2023 |

772,6 |

|

December 2023 |

1 103,5 |

a

b

c

Diagram of the distribution of electricity consumption by month:

a – in a small enterprise; b – in an average enterprise; с – in a large enterprise

These diagrams show that the most increased power consumption is observed in the period December-February, that is, the winter months. This is due to the following factors:

1. The winter months are characterized by cold weather, which leads to an increase in the use of heating systems, especially at large production sites. This requires a large amount of electricity to heat the workrooms and maintain the necessary temperature conditions for the equipment.

2. Shortened daylight hours. This leads to the need for high costs for lighting areas.

3. Increased demand for services. Customers try to repair or maintain ships in order to ensure their proper operation during the months of navigation. Shipyards speed up processes in the winter months so that ships can be tested in the spring and summer period.

Identification of key factors affecting the energy efficiency of enterprises

The use of energy-efficient technologies and equipment can significantly increase the energy efficiency of enterprises. This includes measures such as the installation of energy-efficient air conditioning systems in the hot climate of the Astrakhan region, the replacement of outdated equipment with more efficient, the use of LED lighting and others.

The implementation of Energy Management Systems (EMS) allows enterprises in the region to effectively control and optimize energy consumption. These are monitoring and analysis of energy consumption, installation of automated control systems, and energy audit programs.

Training employees on energy conservation and energy efficiency can lead to a more conscious use of energy in the enterprise. For example, training on the optimal use of equipment, energy saving practices in the workplace, etc., taking into account the specifics of the local industry.

Identification and elimination of sources of energy losses, as well as optimization of production processes, significantly reduce energy consumption in the enterprise. Such measures as the introduction of thermal insulation measures for a region with a hot climate and high temperatures, regular maintenance of equipment, optimization of production processes eliminate sources of losses.

The introduction of alternative energy sources, such as solar and wind, which are relevant for the Astrakhan region, due to the large number of sunny days and open wind spaces, or energy recovery, can significantly reduce the dependence of enterprises on traditional energy sources and reduce their impact on the environment.

Compliance with legislation and standards in the field of energy conservation and energy efficiency also plays an important role [2]. The program [3] is aimed at stimulating enterprises to improve energy efficiency.

Successful energy efficiency of enterprises in the region often depends on an integrated approach that includes various aspects of management, technology, staff training and compliance with standards. Taking into account the climatic and economic characteristics of the region, it is necessary to adapt energy saving strategies to local conditions in order to achieve the best results.

Identify potential areas for improving energy efficiency

Based on the analysis, the authors identified the following potential areas for electrical energy saving.

One of the main areas for improving energy efficiency is the optimization of production processes and technologies. For example, the introduction of more energy-efficient methods of metal processing, manufacturing and installation of ship components, and a more energy-efficient welding method is described in [7].

The equipment of enterprises is quite expensive. Replacing outdated equipment with more energy efficient equipment will lead to significant reductions in energy consumption. The introduction of energy-efficient electric drives, lighting, air conditioning systems and other systems will also help to improve energy efficiency [8].

Enterprises do not use non-traditional and renewable sources of electric energy. However, the work [9] highlights their advantages. Energy recovery is a promising area of further research.

The active development and application of energy saving technologies can have a minimal impact on the enterprise if the appropriate personnel are not available for the process of this transformation [10]. Training employees on energy conservation and energy efficiency can help create a culture of conscious energy use in an enterprise. Conducting trainings, seminars and training programs on the optimal use of equipment and resources will significantly affect energy efficiency.

Conclusion

Based on the results of the analysis, the following conclusions can be drawn:

1. The ship repair and shipbuilding industry in the Astrakhan region has an extensive history and is one of the key ones for the development of the region.

2. The following consumers are the most energy-consuming: electric furnaces, electric welding, universal machines, specialized, aggregate machines.

3. A significant increase in electricity consumption is observed in winter, such months as December, January and February, due to weather conditions, shortened daylight hours, increased demand for services.

4. When managing power consumption at ship repair enterprises, it is important to introduce energy-saving technologies, effective management and monitoring systems to ensure optimal use of resources and reduce energy costs.

5. Potential areas for improving energy efficiency include the following: optimization of technological processes, personnel training, equipment replacement, use of non-traditional energy sources, energy recovery.

1. Тактаров Г. А., Набиев Р. А., Кондрицкий М. А. Анализ состояния и тенденций развития судостроительно-судоремонтной отрасли Российской Федерации // Вестн. Астрахан. гос. техн. ун-та. Сер.: Экономика. 2013. № 2. С. 118–126.

2. Об энергосбережении и повышении энергетической эффективности и о внесении изменений в отдельные законодательные акты Российской Федерации: Федеральный закон РФ от 23.11.2009 № 261-ФЗ. М.: Стандартинформ, 2009. 31 с.

3. Утверждена государственная программа «Развитие судостроения на 2013–2030 годы» // Судостроение. 2013. № 1 (806). С. 11–12.

4. Воловик К. Как себя чувствует морская индустрия Астраханской области // Корабел. газета. URL: https://www.korabel.ru/news/comments/kak_sebya_chuvstvuet_morskaya_industriya_astrahanskoy_oblasti.html (дата обращения: 25.02.2024).

5. Сухорукова К. Н., Бабошкина П. А. Перспективы развития судостроения в Астраханской области // Фундаментальные и прикладные науки сегодня: материалы X Междунар. науч.-практ. конф.: в 3-х т. (North Charleston, USA, 26–27 декабря 2016 г.). North Charleston, USA: CreateSpace, 2016. Т. 2. С. 174–177.

6. О развитии малого и среднего предпринимательства в Российской Федерации: Федеральный закон РФ от 24.07.2007 № 209-ФЗ. М.: Консультант Плюс, 2007. 21 с.

7. Смирнов И. В., Смирнова А. И., Архипкин Д. И. Возможности применения энергоэффективной технологии дуговой сварки с управляемым тепловложением для сварки в защитном газе плавящимся электродом // Альтернатив. энергетика и экология. 2012. № 12. С. 108–111.

8. Зильберова И. Ю., Петров К. С., Кирьянова А. А., Тарчоков А. Д. Использование энергоэффективного оборудования в ремонтностроительном производстве // Инженер. вестн. Дона. 2018. № 2 (49). URL: https://cyberleninka.ru/article/n/ispolzovanie-energoeffektivnogo-oborudovaniya-v-remontnostroitelnom-proizvodstve (дата обращения: 20.02.2024).

9. Сибикин Ю. Д., Сибикин М. Ю. Нетрадиционные и возобновляемые источники энергии. М.: Кнорус, 2012. 232 с.

10. Суворова А. А. Значимость обучения персонала технологиям энергоэффективности // Экономика и бизнес: теория и практика. 2020. № 5-2. С. 189–192.