Россия

Астрахань, Россия

Астрахань, Астраханская область, Россия

В статье приведен обзор литературных источников по вопросам переработки различных видов водорослей с целью получения ценных веществ. Показаны перспективы промышленной переработки водорослей и получения биологически активных веществ. Водоросли перерабатываются с целью производства уникальных по структуре и свойствам полисахаридов и других ценных компонентов биомассы, которые представляют интерес для практического применения как биологически активные соединения с целью их использования в пищевой промышленности, биотехнологии и медицине. Ключевой стадией, которая определяет эффективность переработки водорослей с целью получения биологически активных соединений, является экстракция. Проанализированы конструкции аппаратов для экстракции в системе экстрагент – твердое тело. На основе систематизации известных в литературе способов экстракции и их технического обеспечения сделан вывод о том, что для интенсификации массообменных процессов при экстрагировании водорослей, целесообразно использовать воздействие ультразвукового излучения на экстракционную смесь (сырье и экстрагент). Ультразвуковая экстракция позволяет интенсифицировать массообменные процессы, увеличивать выход получаемых продуктов и повышать их качественные показатели. Разработана конструкция установки для ультразвуковой экстракции измельченного растительного сырья – различных видов водорослей, в принципе работы которой сочетаются различные методы интенсификации процесса экстракции: ультразвуковая обработка экстракционной смеси при ее непрерывном механическом и циркуляционном перемешивании. Ультразвуковая экстракционная установка позволяет перерабатывать различные водоросли при различных температурных режимах и использовании различных экстрагентов. Приведено устройство разработанной установки и описан принцип ее работы. Показаны преимущества установки по отношению к известным конструкторским решениям. Данная конструкция рекомендована для включения в состав технологических линий по переработке водорослей.

водоросли, химический состав, экстракция, методы интенсификации, ультразвуковое воздействие, экстрактор

Introduction

Currently, algae are actively processed to produce polysaccharides that are unique in structure and properties (alginic acids, agar-agar, furcellaran, carrageenans, etc.) [1]. In addition, the complex processing of algae produces other valuable components of biomass, which include polysaccharides - laminarans and fucoidans and low-molecular metabolites - free amino acids, polyphenols, iodine-containing compounds, vitamins, lipids [2]. All these substances are of interest for practical use as biologically active compounds [3-9], which are widely used in the food industry, biotechnology and medicine.

Algae are sources of protein and microelements that are little used in world practice. Artificial cultivation of certain types of algae in the future can become a profitable business, especially in conditions of increased demand for environmentally friendly, in particular, protein products of plant origin.

Algae, due to their habitat, can use carbon dioxide and nutrients more efficiently than terrestrial plants, resulting in increased growth rates. Algae are more resistant to the negative effects of the environment, which simplifies the conditions for their cultivation and collection for the production of biomass, which can be used as food and for the production of biofuel, food additives and in cosmetology.

The key stage that determines the efficiency of algae processing to obtain biologically active compounds is extraction. Systematization of extraction methods known in the literature and their technical support [1-5] allows us to conclude that in order to intensify mass transfer processes when extracting raw materials of plant origin, in particular algae, it is advisable to use the effect of ultrasonic radiation on the extraction mixture (raw materials and extractant).

Objects and methods of research

The object of the study was the method of ultrasonic extraction of polysaccharides from algae and the design of the installation for its implementation. The subject of the study is the process of extraction of polysaccharides from algae.

Results and discussion

Considerable attention is paid to improving technologies and developing methods for obtaining polysaccharides from algae; analysis of research work in this area has made it possible to identify a number

of promising technologies. For example, there is a known method for obtaining biologically active water-soluble polysaccharides, in particular, laminarans and fucoidans [10], including the treatment of fresh,

or fresh frozen, or dry algae with solvents to remove low molecular weight substances, extraction of polysaccharides with hydrochloric acid and water, subsequent separation of laminarans and fucoidans and their fractionation.

There is a known method for producing gel-forming agar polysaccharide from red algae (Ahnfeltia tobuchiensis, Ahnfeltia plicata or Gracilaria verrucosa), which includes preparation of algae, pre-treatment, extraction, purification of extracts, their dehydration and drying [11].

A method has been proposed for processing brown algae – kelp and Fucus vesiculosa [12] to obtain lipid concentrates and water-soluble concentrates rich in iodine. This method makes it possible to most fully extract the fat-soluble part of brown algae, rich in unsaturated fatty acids, and use it as a substance for the production of therapeutic and prophylactic additives, and the powder obtained from water-soluble substances of brown algae extract, which is a complex of polysaccharides, mannitol, vitamins, minerals, can be used as a food and preventive additive in the food industry.

In the work of Mukatova M. D. [13] describe studies of the colloidal properties of polysaccharides obtained from aquatic plants – zosterol and pondweed. During the research, the possibility of their use as structure formers was established and the organoleptic and physicochemical properties of the extracts were studied.

Tabakaev A. V. work [14] presents the results of studying the influence of hydrothermal extraction methods (infusion, boiling and autoclaving) and the duration of the process on the yield of an extract containing water-soluble components of algae. Brown algae from the Sea of Japan – Costaria costata, Undaria pinnatifida, Sargassum miyabei Yendo – were used as raw materials to obtain extracts. A comparative analysis of the quantitative yield of extracts using various methods was performed.

The work [15] presents the results of optimization of the extraction process of a certain type of fucoidan and high biological activity from the brown algae Fucus evanescens.

Podkorytova A. V. in [16] provides a review of the scientific literature on the distribution, reserves and use of algae in the White and Black Seas of the coastal zones of Russia. Data on studies of the chemical composition, technological properties and chemical structure of brown algae polysaccharides are presented. The prospects of using algae for the production of various products are shown.

In the work of Usoltseva R. V. [17] provides general information about laminarans – polysaccharides of brown algae, describes methods for their isolation, establishment of structures and known structural types, and also discusses the prospects for using laminarans from Far Eastern brown algae.

Salieva A. R. is studying the chemical and carbohydrate composition of Caspian zoster and pierced-leaved pondweed [18], significant reserves of which are in the Volga River delta and the territory of the Northern Caspian Sea. In addition, the author analyzed the change in the carbohydrate composition of algae during their processing. A large amount of pectin and mineral substances has been established, which allows the use of algae to obtain pectin substances and carbohydrate-mineral supplements. A new physical method for processing raw materials with ultrahigh frequency waves has been proposed.

To extract various biologically active substances from algae, various methods and process organization schemes can be used (maceration, remaceration, percolation, repercolation, centrifugal extraction, ultrasonic extraction and others). In order to develop the design of a universal installation for processing various algae, an analysis of traditional and improved extractor designs was carried out based on patent information.

Borodulin D. M., Shalev A. V. and Prosin M. V. proposed a batch extractor for extracting target components with recycling channels (Fig. 1), which can be used in pharmaceutical, biochemical, food and other industries [19].

Fig. 1. Periodic extractor for extracting target components with recycle channels [19]:

1 – cylindrical body; 2 – perforated cover; 3 – handle; 4 – pressure gauge; 5 – excess pressure relief valve;

6, 7 – pipes; 8 – recycle channels; 9 – gas distribution device; 10 – pipe for oxygen supply

The periodic extractor contains a cylindrical body with a perforated flat cover equipped with a pressure gauge and an excess pressure relief valve, as well as a handle for closing the holes in the device cover. The body has a pipe for supplying extractant and solid phase, a pipe for exiting the finished product and two recycle channels. At the bottom of the apparatus there is a gas distribution device with a pipe for supplying oxygen. Technical result: increasing the intensity of the process of extracting target components from the solid phase due to the uniform introduction of oxygen into the extractor, leading to the creation of a bubble layer and repeated mixing of solid particles throughout the entire volume of the extractant.

The disadvantage of this device is that this apparatus operates in a periodic mode, which causes additional labor costs for loading and unloading, as well as a decrease in the driving force of the extraction process

and, as a consequence, a decrease in its intensity.

Sorokopud A. F., Ivanov P. P. and Khalturin M. A. developed a vibrating extractor [20], which includes a vertical body with a flat bottom, separated by spiral partitions of a special configuration with guide grooves, a vertical drive shaft with a traverse on which two belt or chain conveyors, on which, with the possibility of axial movement along their branches, roller supports, means for supplying and discharging raw materials and extractant, connected to mutually overlapping elements of the blades and placed in guide grooves, are fixed. The extractor has increased reliability due to the absence of stagnant zones in the spiral channels and allows you to intensify the extraction process by increasing the frequency of changes in the phase contact surface in a spiral channel of variable width (Fig. 2).

Fig. 2. Vibrating extractor [20]: 1 – vertical body; 2 – perforated plates; 3 – rod;

4 – cover; 5-7 – input devices; 8 – phase output devices; 9 – hinge; 10 – feed auger

The negative aspects of this device include the complexity of the design with the presence of moving elements, in which the intensification of the process due to vibration and renewal of the phase contact surface is insignificant, especially for highly adhesive products, due to the adhesion of raw material particles to load-bearing surfaces.

Franko E. P., Kasyanov G. I., Korobitsyn V. S. [21] proposed a promising installation for gas-liquid extraction of raw materials (Fig. 3), which contains a technologically connected and sequentially interacting sealed housing, a quick-release self-sealing hatch, a glass extractor, and a funnel for collecting condensate, cooler, heater, turntable, manipulator handle, miscellaneous collectors, generator, an additional generator is installed, which is an ultrasonic vibration generator.

The negative aspects of this installation include the complexity of the design and non-residue intensification of the extraction process due to the impossibility of practical implementation of active hydrodynamic modes of phase interaction.

Ultrasonic extraction makes it possible to intensify mass transfer processes, increase the yield of the resulting products and improve their quality indicators.

To extract various biologically active substances from algae, a universal design of an ultrasonic extraction installation has been developed [19, 20].

Fig. 3. Installation for gas-liquid extraction

of raw materials [21]: 1 – body; 2 – hatch; 3 – glass extractor; 4 – funnels for collecting condensate;

5 – cooler; 6 – heater; 7 – manipulator handles; 8 – miscellaneous collector; 9 – rotary table; 10 – ultrasonic vibration generator

The operating principle of the installation is based on a combination of various methods of intensifying the extraction process: ultrasonic treatment of the extraction mixture with its continuous mechanical and circulation mixing. The installation allows you to process various algae at different temperatures and using different extractants.

In a device containing a vertically located cylindrical body with process nozzles and a thermostatic jacket, a drive mixer coaxially installed in the body, bumpers located along the periphery of the body, rigidly fixed on the inner surface of the cylindrical body, while the drive mixer has a frame structure consisting of a shaft mounted on the shaft of the horizontal and vertical blades and the anchor part, rigidly connected to the vertical blades and the shaft, the extractor has a cover rigidly fixed to the cylindrical body, ultrasonic generators equipped with rod working elements located between the vertical blades and the mixer shaft are installed and rigidly fixed on the extractor cover, transmitting ultrasonic vibrations of the extracted mixture, and the extractor cover has holes for rod working elements rigidly attached to ultrasonic generators.

Fig. 4 shows the proposed ultrasonic installation (general view, top view, ultrasonic extractor in cross section).

|

а |

b

|

|

c |

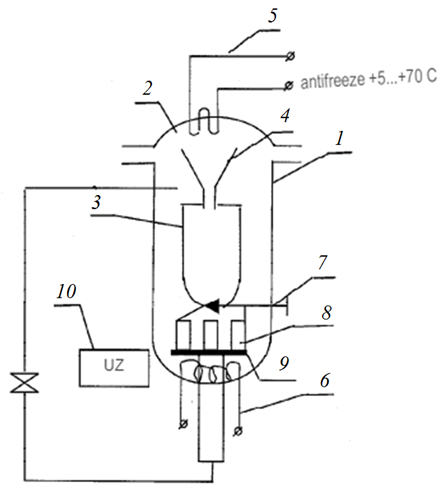

Fig. 4. Ultrasonic extraction installation:

a – general view; b – top view; c – ultrasonic extractor in cross section:

1 – cylindrical body; 2-4 – process pipes; 5 – thermostatting jacket with pipes;

6-8 – bumpers; 9 – driven frame mixer; 10 – shaft; 11 – horizontal blades;

12 – vertical blades; 13 – anchor part; 14 – cover; 15 – ultrasonic generators;

16 – rod working elements; 17 – holes for rod working elements

The installation works as follows. The extraction mixture is formed in the volume of a cylindrical body 1, the loading of raw materials and extractant is carried out through the process pipe 2. Mechanical mixing is carried out by a driven frame mixer 9, consisting of a shaft 10, horizontal blades 11, vertical blades 12 and an anchor part 13. The design of the frame mixer 9 allows for efficient stir the mixture in the working volume of housing 1 and intensify heat exchange processes during thermostatting. The presence of bumpers 8, rigidly fixed on the inner surface of the cylindrical body 1, eliminates the negative effect of funnel formation during mechanical mixing of the mixture. Circulation mixing of the mixture is carried out as a result of selecting part of the mixture through pipe 4 and directing this mixture to the upper part of the apparatus through pipe 3. Circulation mixing allows the extraction mixture to be evenly distributed throughout the volume of the apparatus. To create and maintain the required temperature of interaction of the mixture during extraction, the apparatus uses a thermostatting jacket 5 with pipes 6 and 7 for inlet and outlet of coolant. Ultrasonic vibrations are transmitted to the mixture from ultrasonic generators 15 through rod working elements 16, which are immersed in the mixture in the space between the vertical blades 11 and the shaft 10 of the mixer 9. After completion of the extraction process, the mixture is removed from the apparatus for further separation into extract and waste raw materials through pipe 4.

For the scientific and practical substantiation and development of a rational method of extraction and the design of the installation for its implementation, an analysis of a number of well-known design solutions was carried out [21-29], in comparison with which the proposed ultrasonic extractor has a number of advantages:

– the design of the apparatus allows the extraction process to be implemented in a continuous mode, by continuously supplying the extraction mixture to the upper part of the apparatus through a pipe and discharging the waste mixture through a pipe at the bottom of the apparatus;

– depending on the type of extractant, extraction modes, mechanical and circulation mixing of the mixture and the influence of ultrasonic vibrations on it can be carried out either continuously during the extraction process or periodically in various combinations, implementing oscillating modes of processes affecting the mixture during extraction;

– mixing with a stirrer and circulation increase the

rate of heat and mass transfer and exchange of target components at the boundary between phases during extraction, promoting the formation of a developed phase contact surface and its renewal through convective diffusion processes [9];

– the influence of ultrasound on the composition increases the speed of the process of passage of the extractant through the porous structure of the raw material, the actual extraction and dissolution of the target components in the extractant [10, 11].

Conclusion

A design has been developed for an installation for ultrasonic extraction of crushed plant materials – various types of algae, the principle of which combines various methods of intensifying the extraction process: ultrasonic treatment of the extraction mixture with its continuous mechanical and circulation mixing. Further development is being carried out in research aimed at assessing the specific productivity of the developed plant design for various types of algae and determining the range of variation of the main factors affecting the productivity of the extraction plant. This design is recommended for inclusion in technological lines for processing algae and obtaining various biologically active substances using various extractants.

1. Phillips G. O., Williams P. A. Handbook of Hydrocolloids. Cambridge, UK: Woodhead Publishing Limited, 2009. 775 с.

2. Хотимченко С. В. Липиды морских водорослей-макрофитов и трав: структура, распределение. Владивосток: Дальнаука, 2003. 230 с.

3. Шевченко М. Н., Анастюк С. Д., Герасименко Н. И., Дмитренок П. С., Исаков В. В., Звягинцева Т. Н. Полисахаридный и липидный состав бурой водоросли Laminaria gurjanovae // Биоорганическая химия. 2007. Т. 33. № 1. С. 96–107.

4. Chevolot L., Foucault A., Ratiskol J., Colliec-Jouault S. A disaccharide repeat unit is the major structure in fucoidans from two species of brown algae // Carbohydrate Research. 2001. V. 330. N. 4. P. 529–535. DOI:https://doi.org/10.1016/S0008-6215(00)00314-1.

5. Zvyagintseva T. N., Shevchenko N. M., Luk'yanov P. A., Nazarova I. V., Scobun A. S., Elyakova L. A. Inhibition of complement activation by water-soluble polysaccharides of some fareastern brown seaweeds // Comparative Biochemistry and Physiology. Part C: Pharmacology, Toxicology and Endocrinology. 2000. V. 126. N. 3. P. 209–215. DOI:https://doi.org/10.1016/S0742-8413(00)00114-6.

6. Zvyagintseva T. N., Shevchenko N. M., Popivnich I. B., Isakov V. V., Scobun A. S., Sundukova E. V, Elyakova L. A. A new procedure for the separation of water-soluble polysaccharides from brown seaweeds // Carbohydrate Research. 1999. V. 322. N. 1-2. P. 32–39. DOI:https://doi.org/10.1016/S0008-6215(99)00206-2.

7. Kim M. K., Dubacq J. P., Thomas J. C., Giraud G. Seasonal variations of triacylglycerols and fatty acids in Fucus serratus // Phytochemistry. 1996. V. 43. N. 1. P. 49–55. DOI:https://doi.org/10.1016/0031-9422(96)00243-9.

8. Усов А. И., Смирнова Г. П., Клочкова Н. Г. Полисахариды водорослей. Полисахаридный состав некоторых бурых водорослей Камчатки // Биоорганическая химия. 2001. Т. 27. № 6. С. 444–448.

9. Наумов И. А., Буркова Е. А., Канарская З. А., Ка-нарский А. В. Водоросли – источник биополимеров, биологически активных веществ и субстрат в биотехнологии. Ч. 1. Биополимеры клеток тканей водорослей // Вестн. Технолог. ун-та. 2015. Т. 18. № 1. С. 184–188.

10. Пат. № 2135518 C1 РФ, МПК C08B 37/00, C07H 1/08, C08B 37/18. Способ получения водорастворимых полисахаридов бурых водорослей / Звягинцева Т. Н., Шевченко Н. М., Попивнич И. Б., Светашева Т. Г., Исаков В. В., Скобун А. С., Елякова Л. А. № 98111675/04: заявл. 17.06.1998; опубл. 27.08.1999.

11. Пат. № 2770383 C2 РФ, МПК C08B 37/12. Способ получения гелеобразующего полисахарида агара из красных водорослей / Подкорытова А. В., Бурова Н. В.; № 2019139418: заявл. 04.12.2019; опубл. 15.04.2022.

12. Пат. № 2132622 C1 РФ, МПК A61K 36/03, A23L 1/0532. Способ переработки бурых водорослей / Некрасова В. Б., Никитина Т. В., Курныгина В. Т., Белозерских О. А.; № 98104941/13: заявл. 16.03.1998; опубл. 10.07.1999.

13. Мукатова М. Д., Бисенова А. Р., Курганова М. В. Изучение коллоидных свойств растворов полисахаридов высших водных растений Волго-Каспийского бассейна // Вестн. Астрахан. гос. техн. ун-та. Сер.: Рыбное хозяйство. 2011. № 1. С. 127–132.

14. Табакаев А. В., Табакаева О. В. Влияние методов гидротермической экстракции и времени на выход экстракта бурых водорослей Японского моря // Индустрия питания. 2021. Т. 6. № 3. С. 44–50. DOI:https://doi.org/10.29141/2500-1922-2021-6-3-5.

15. Имбс Т. И., Харламенко В. И., Звягинцева Т. Н. Оптимизация процесса экстракции фукоидана из бурой водоросли Fucus evanescens // Морские прибрежные экосистемы. Водоросли, беспозвоночные и продукты их переработки: тез. докл. Четвертой междунар. науч.-практ. конф. (Южно-Сахалинск, 19–22 сентября 2011 г.). Южно-Сахалинск: Изд-во Сахалин. науч.-исслед. ин-та рыб. хоз-ва и океанографии, 2011. С. 224–225.

16. Подкорытова А. В., Усов А. И., Евсеева Н. В., Рощина А. Н. Промысловые водоросли Белого и Черного морей прибрежных зон России: запасы, химический состав, строение, свойства полисахаридов, рациональное использование // Тр. ВНИРО. 2023. Т. 193. С. 190–215. DOI:https://doi.org/10.36038/2307-3497-2023-193-190-215.

17. Усольцева Р. В., Звягинцева Т. Н., Ермакова С. П. Структурное разнообразие ламинаранов бурых водорослей, перспективы их использования // Вестн. Дальневосточ. отд-ния Рос. акад. наук. 2019. № 5 (207). С. 84–89. DOI:https://doi.org/10.25808/08697698.2019.207.5.010.

18. Салиева А. Р., Мукатова М. Д. Пектиновые вещества высших водных растений Волго-Каспия и способы их извлечения // Вестн. Астрахан. гос. техн. ун-та. Сер.: Рыбное хозяйство. 2009. № 1. С. 160–165.

19. Пат. № 2707219 C1 РФ, МПК B01D 11/02. Экс-трактор периодического действия для извлечения целе-вых компонентов с рецикл-каналами / Бородулин Д. М., Шалев А. В., Просин М. В., Вечтомова Е. А., Потураева Н. Л., Демченко К. Э.; № 2019109707: заявл. 02.04.2019; опубл. 25.11.2019.

20. Пат. № 2257937 C1 РФ, МПК B01D 11/02. Экс-трактор вибрационный / Сорокопуд А. Ф., Иванов П. П., Кустов И. Н.; № 2004102772/15: заявл. 30.01.2004; опубл. 10.08.2005.

21. Пат. № 93294 U1 РФ, МПК B01D 11/02. Установка для газожидкостной экстракции сырья / Франко Е. П., Касьянов Г. И., Коробицын В. С.; № 2010104163/22: заявл. 08.02.2010; опубл. 27.04.2010.

22. Пат. № 225428 U1 РФ, МПК B01D 11/02, F26B 5/02. Ультразвуковой экстрактор / Коннова О. И., Золотовская О. В., Свирина С. А., Мемедейкина Н. П., Теличкина Э. Р., Максименко Ю. А., Алексанян И. Ю.; № 2024107398: заявл. 21.03.2024; опубл. 22.04.2024.

23. Коннова О. И., Золотовская О. В., Свирина С. А., Максименко Ю. А. Разработка рациональной конструкции ультразвукового экстрактора // Технологии и продукты здорового питания: материалы XIII Национ. науч.-практ. конф. с междунар. участием (Саратов, 21 марта 2024 г.). Саратов: Изд-во Сарат. гос. ун-та генетики, биотехнологии и инженерии им. Н. И. Вавилова, 2024. С. 190–195.

24. Пат. № 2035884 C1 РФ, МПК A23N 1/00, A23L 1/308, B01D 11/02. Экстрактор для обработки плодово-ягодных выжимок / Ломачинский В. А., Квасенков О. И., Касьянов Г. И.; № 93054183/13: заявл. 07.12.1993; опубл. 27.05.1995.

25. Пат. № 2221036 C2 РФ, МПК C12G 3/00, B01F 11/02. Ультразвуковой экстрактор / Маргулис М. А., Поролло В. А., Васильченко С. В., Оганесянц Л. А., Телегин Ю. А.; № 2000130370/13: заявл. 05.12.2000; опубл. 10.01.2004.

26. Пат. № 2257937 C1 РФ, МПК B01D 11/02. Экс-трактор вибрационный / Сорокопуд А. Ф., Иванов П. П., Кустов И. Н.; № 2004102772/15; заявл. 30.01.2004; опубл. 10.08.2005.

27. Пат. № 63240 U1 РФ, МПК B01D 11/02, B06B 1/06. Ультразвуковой экстрактор / Зуев Н. М., Михайлин Н. Ю., Дубницкий С. Г.; № 2006146414/22; заявл. 25.12.2006; опубл. 27.05.2007.

28. Пат. № 2796825 C1 РФ, МПК B01D 11/02, B06B 1/06. Ультразвуковой экстрактор / Овсянников В. Ю., Дранникова Н. Е., Макеева Е. О.; № 2022127334: заявл. 21.10.2022; опубл. 29.05.23.

29. Пат. № 178562 U1 РФ, МПК B01D 11/02, B06B 1/18, C11B 1/10. Гидродинамический экстрактор / Муцаев Р. В., Алексанян И. Ю.; № 2017126746: заявл. 25.07.2017; опубл. 09.04.2018.