Россия

Траловые мешки представляют собой сетные цилиндрические конструкции, которые изготовлены из дели различного материала и поворота ячей, это может быть традиционная T0 или дель, повернутая на 90° – T90. Траловые мешки состоят из рубашки, шаг ячеи которой устанавливается правилами рыболовства или конвенциями того или иного района промысла, самого тралового мешка. Траловый мешок для прочности окружает каркас, который изготавливается из канатов. В некоторых случаях в прибрежном рыболовстве и во внутренних водах используют только мешок, без рубашки и каркаса, при этом сам мешок выполняет несколько функций: облов гидробионтов в соответствии с правилами рыболовства и удержание улова. Такие траловые мешки применяются в научных целях при облове ряпушки (Coregonus albula) в оз. Виштынецкое Калининградской области. Удерживающие качества траловых мешков сопряжены с их селективностью, это означает удержание тех гидробионтов, которых возможно изымать из водоема, причем не повреждая самих водных организмов и не подрывая биомассу прибрежных вод, озер и водохранилищ. Как правило, дель с ячеей T0 имеет меньшие селективные свойства по сравнению с делью T90, т. к. в дели T90 нет острых углов соприкосновения веревок одной ячеи, что предотвращает зажимание в ней гидробионтов, к тому же такой делью лучше, с точки зрения уловистости, удерживать гидробионты с овальным телом. Также траловые мешки с делью T90 имеют меньшее гидродинамическое сопротивление по сравнению с делью T0, что позитивно влияет на гидродинамическое сопротивление самой траловой системы, и траловые мешки, изготовленные из дели T90, способствуют сохранению цилиндрической формы тралового мешка в процессе траления и удержания улова, это связано с формой ячеи и физико-механическими свойствами веревок, из которых изготовлена дель тралового мешка. В ходе проведения исследований получены эмпирические зависимости коэффициента гидродинамического сопротивления траловых мешков, изготовленных из дели T0 и T90, материал полиамид. Меньшее сопротивление показали капроновые траловые мешки, изготовленные из дели T90. Сопротивление таких мешков на 11 % меньше традиционных траловых мешков.

траловый мешок, ячея, T0, T90, гидродинамическое сопротивление, эмпирические зависимости

Introduction

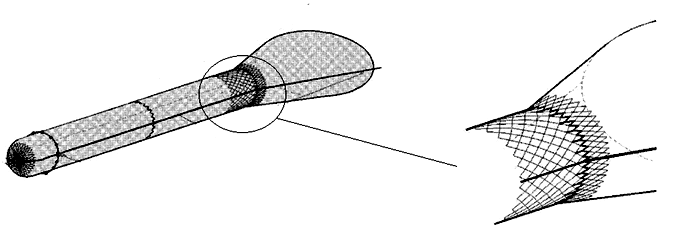

Preserving the diversity of hydrobionts of the World Ocean, and catching the necessary mass of them is a priority task of pro-industrial fishery. The connection of the two tasks is reduced to the reasonable design and application of сod-ends of different depth and bottom trawls to retain hydrobionts in the сod-end [1]. Сod-ends are netting cilindrical structures which are made of netting of different material and mesh rotation, it can be traditional T0 and with 90° T90 rotation. Сod-ends consist of a jacket, the mesh pitch of which is set by fishing regulations or conventions of a particular fishing area, the сod-end itself, the mesh of which is larger than the mesh pitch of the jacket and by a factor of two, three or four, with a multiple, as a rule, a netting with a larger diameter is chosen and may consist of two ropes (Fig. 1).

Fig. 1. Сod-end

For strength, a frame is built on top of the bag, which is made of ropes. In some cases, in coastal fisheries and inland waters, only the bag without the jacket and frame is used, with the bag itself performing several functions: trawling for hydrobionts in accordance with fishing regulations and retaining the catch. Such сod-ends are used for scientific purposes when fishing for ruffed grouse (Coregonus albula) in Lake Vishtynetskoe, Kaliningrad region. Retention qualities of сod-ends are connected with their selectivity, it means retention of those hydrobionts, which can be removed from the water body without damaging aquatic organisms and without undermining the biomass of coastal waters, lakes and reservoirs. As a rule, netting with T0 mesh has less selective properties in comparison with netting T90, as in netting T90 there are no sharp angles of contact of ropes of one mesh, which provides not clamping in it hydrobionts, besides such netting is better from the point of view of catch-ability to hold hydrobionts with an oval body in the cross-section. Also сod-ends with T90 contribute to the preservation of the cylindrical shape of the сod-end in the process of trawling and catch retention, this is due to the shape of the mesh and physical and mechanical properties of the ropes from which the netting of the сod-end is made [2-4].

The following factors should be considered in the design of сod-ends:

– mesh opening;

– shape of the сod-end;

– rope strength;

– knot strength;

– rope material.

The mesh opening is related to the shape of the сod-end and rope material. The strength of the ropes is selected from the hydrodynamic resistance of the сod-end and the weight of the catch attributed to the ropes in the mesh, taking into account their material and the rope safety factor specified by the designer. The strength of the knots for the T90 is an important problem that can only be solved by selecting knots that can withstand the required load by experimentation on experimental units. The material of ropes used to make сod-ends is diverse, it can be polyamide, polyethylene, polyester etc. There can be mixed material of rope fibers, there can be both polyamide and polyethylene fibers in one rope in percentage ratio. In all cases, the main physical and mechanical property of ropes is elasticity, which can be longitudinal, transverse and torsional. In our case, for the mesh shape, it is useful to know the bending strength of ropes E, on which the mesh shape T90 depends.

The hydrodynamic resistance of the сod-end has the greatest influence on the mesh shape, in addition to the given mesh parameters [5]. Scientists from many countries are studying this issue [3, 6, 7].

When justifying the choice of a сod-end for multidepth or bottom trawls with T0 or T90 mesh, it is necessary to take into account all factors that influence the shape of the trawl structure, in particular the сod-end. In the article the influence of сod-end mesh shape on hydrodynamic resistance is considered. In this case the material of ropes polyamide is chosen, this material has proved itself well at manufacturing of nettings, and, having high elasticity, which fibers allow ropes to take the form of a mesh, which is necessary for designers and operators of trawls.

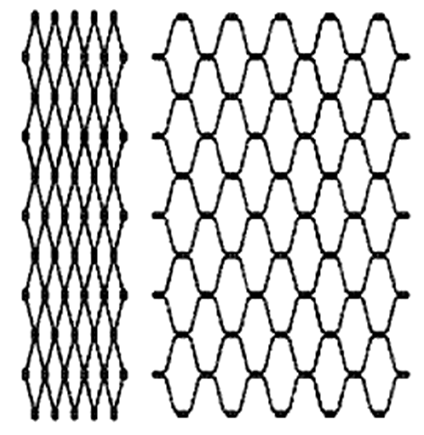

Fig. 2 shows the traditional T0 and 90-degree T90 mesh shapes.

Fig. 2. Mesh shape T0 and T90

When investigating the hydrodynamics of сod-ends, attention should be paid to the shape in plan of the ropes and the continuity of these structures. Let's introduce the assumption that the continuity of netting T0 and T90 is determined by the same formula:

![]()

where d – rope diameter; a – mesh pitch; ux – planting coefficient for the length of the сod-end; uy – planting coefficient for the height of the сod-end.

Problem statement

The research problem of the сod-end design problem of multi-depth and bottom trawls is based mainly on the search for a solution to the selectivity of сod-ends, in particular, to catch the necessary mass of commercial hydrobionts without damaging individuals.

When operating a multi-depth trawl with a T0 сod-end on Lake Vishtynetskoye [8], we encountered the problem of opening the сod-end. There was a problem of hydraulic support in the place of connection of the сod-end to the end part of the trawl (see Fig. 1). This problem was solved by turning the сod-end netting from T0 to T90. The experiments were conducted at the quarry of Gvardeysky settlement.

The effects of netting deployment in the fishery could not be determined due to lack of advisory equipment (video and fish entry sensors in the сod-end).

In order to make an informed decision on the choice

of T0 or T90 netting spread, it was decided to conduct a series of experiments with T0 and T90 сod-ends. In order to make an informed decision on the choice of T0 or T90 netting spread, it was decided to conduct a series of experiments with T0 and T90 сod-ends in Fischering Service hydrochannel. The parameters of the сod-end netting are given in Table 1.

Table 1

Characteristics of netting сod-ends

|

Mesh shape |

a, mm |

d, mm |

n, mesh |

m, mesh |

Material |

|

Т0 |

8.0 |

1.0 |

320 |

200 |

Polyamide |

|

Т90 |

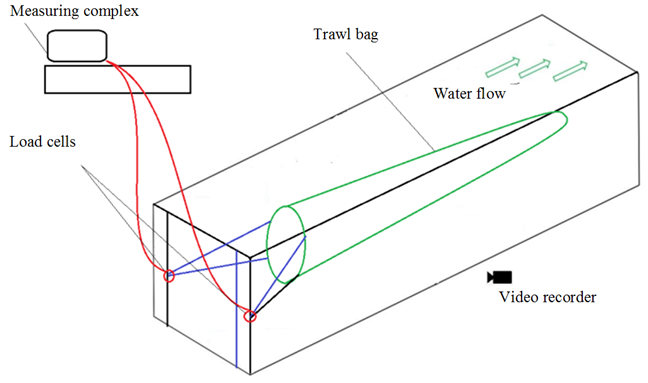

A schematic of the сod-end experiments is given in Fig. 3.

Fig. 3. Scheme of experiments with сod-ends

Fig. 3 shows the working section of hydrochannel “Fischering Service”, a сod-end fixed on a hoop, which ensures opening of the сod-end with a given fit ux. The hydrodynamic resistance was measured by the complex. Video recording of the сod-end with fixation of its opening, as well as the opening of the mesh was carried out by a video camera.

The shape of сod-ends depends on the opening of the place of their connection with the end part (see Fig. 1), in order to set the opening of сod-ends, it was decided to put the upper part of the сod-ends on metal hoops of different diameter D. The experiments were carried out with the use of measuring equipment of hydrochannel “Fischering Service” hydrochannel, сod-ends were fixed on sliding blades with strain gauges installed on them. Characteristics of сod-ends are given in Table 2.

Table 2

Characteristics of сod-ends

|

D, mm |

ux |

uy |

Fo |

|

350 |

0.215 |

0.977 |

0.596 |

|

540 |

0.331 |

0.944 |

0.4 |

|

640 |

0.393 |

0.92 |

0.346 |

Based on the data in Tables 1 and 2, two сod-ends were constructed and alternately seated on metal hoops of different diameters to ensure different seating and netting continuity.

Methods

Сod-end experiments showed a clear dependence on cohesion and mesh shape. In turn, to determine the approximating dependencies, it is necessary to select the approximation coefficients so that the correlation of the dependent factors is clear and the hydrodynamics of the process is understood. Fig. 4 shows two сod-ends, which have the same continuity Fo = 0.346, and are planted on the same metal hoop, the diameter of which is D = 640 mm.

a

Fig. 4. Photos of сod-ends T90 (a)

b

Fig 4 (ending). Photos of сod-ends T0 (b), D = 640 mm, Fo = 0.346

During the experiments, the values of hydrodynamic drag coefficient of сod-ends were obtained – cx (see Table 3).

Table 3

Values of structural and force characteristics of сod-ends

|

Mesh shape |

Fo |

Re* |

cx · 10–3 |

|

Т0 |

0.596 |

750 |

9.22 |

|

1 125 |

5.85 |

||

|

1 563 |

3.83 |

||

|

0.4 |

750 |

12 |

|

|

1 125 |

7.23 |

||

|

1 563 |

4.89 |

||

|

0.346 |

750 |

13 |

|

|

1 125 |

8.38 |

||

|

1 563 |

5.81 |

||

|

Т90 |

0.596 |

750 |

8.27 |

|

1 125 |

5 |

||

|

1 563 |

3.56 |

||

|

0.4 |

750 |

10 |

|

|

1 125 |

6.45 |

||

|

1 563 |

4.59 |

||

|

0.346 |

750 |

13 |

|

|

1 125 |

7.96 |

||

|

1 563 |

5.66 |

* Re – Reynolds number.

To approximate the values, which are presented in Table 3 by the dependence of the following form:

![]() (1)

(1)

where k – is the coefficient depending on the mesh shape T0 or T90, it is necessary to make the following calculations:

– approximation of the form

![]() , (2)

, (2)

for сod-ends separately T0 and T90;

– approximate the form

![]()

where T – is the shape of the mesh T0 or T90.

In order to simplify the approximation dependence in terms of its form, as well as to minimize the approximation error

δ → min

where δ – is the approximation error, it was decided to use an index function of the form:

![]() (3)

(3)

where a – is the approximation coefficient.

Tables 4, 5 show the values of the approximation coefficients (3) and the values of its error.

Table 4

Values of approximation coefficients (3) and values of its error for T0

|

Mesh shape |

Fo |

k |

a |

δ, % |

|

Т0 |

0.596 |

12.9 |

–1.1 |

3.8 |

|

2.9 |

||||

|

–3.4 |

||||

|

0.4 |

16.4 |

3.3 |

||

|

0.2 |

||||

|

2.9 |

||||

|

0.346 |

19 |

0.7 |

||

|

0.2 |

||||

|

–0.3 |

Table 5

Values of approximation coefficients (3) and values of its error for T90

|

Mesh shape |

Fo |

k |

a |

δ, % |

|

Т90 |

0.596 |

11.8 |

–1.1 |

1.9 |

|

–3.8 |

||||

|

–1.6 |

||||

|

0.4 |

14.9 |

–0.7 |

||

|

–1.7 |

||||

|

0.5 |

||||

|

0.346 |

18.4 |

0.7 |

||

|

–1.8 |

||||

|

0.2 |

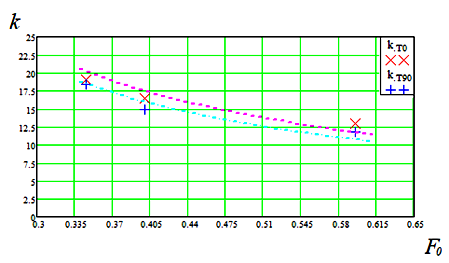

Based on Table 4, the approximating dependence of the form (2) is presented in the form of

![]()

on Fig. 5 shows the data of the coefficient k depending on Fo.

Fig. 5. Dependencies k on Fo

The approximating dependence of the form (1) is presented in the following form:

![]() (4)

(4)

where k = 7 for T0; k = 6.4 for T90.

Results and discussion

As a result of approximation of dependence of the form (1), the relationship between geometric and force parameters of the netting T0 and T90 is obtained, the approximation error does not exceed 9%.

Based on the obtained dependence (4), the resistance of the сod-end made of T90 netting is 11% less than the сod-end made of T0 netting. Dependence (4) is valid for сod-ends made of polyamide.

Conclusion

The conducted research has allowed to obtain a clear dependence of the hydrodynamic drag coefficient of netting, from which сod-ends are made.

The research was carried out within the framework of the state assignment on the theme “Development of physical, mathematical and predictive models of the processes of bottom and multi-depth trawl complexes operation”.

1. Недоступ А. А., Павленко А. А. Обоснование расчета характеристик траловых мешков // Рыбное хозяйство. 2011. № 2. С. 101–103.

2. Graham N., O’Neill F. G. O., Fryer R. J., Galbraith R. D., Myklebust A. Selectivity of a 120 mm diamond codend and the effect of inserting a rigid grid or a square mesh panel // Fisheries Research. 2004. V. 67. P. 151–161.

3. Herrmann B., Wienbeck H., Moderhak W., Stepputtis D., Krag L. The influence of twine thickness, twine number and netting orientation on codend selectivity // Fisheries Research. 2013. V. 145. P. 22–36.

4. Недоступ А. А., Коновалова К. В., Насенков П. В., Ражев А. О., Альтшуль Б. А., Федоров С. В. Относительная жесткость рыболовных крученых изделий // Вестн. Астрахан. гос. техн. ун-та. Сер.: Рыбное хозяйство. 2020. № 1. С. 46–60.

5. Cheng Z., Winger P. D., Bayse S. M., Kelly D. Hydrodynamic Performance of Full-Scale T0 and T90 Codends with and without a Codend Cover // J. Mar. Sci. Eng. 2022. V. 10. P. 440.

6. Graham N., O’Neill F. G. O., Fryer R. J., Galbraith R. D., Myklebust A. Selectivity of a 120 mm diamond codend and the effect of inserting a rigid grid or a square mesh panel // Fisheries Research. 2004. V. 67. P. 151–161.

7. Moderhak W. A theoretical approach to selectivity of cod-ends // Contributions on the Theory of Fishing Gears and Related Marine Systems. 2003. V. 3. P. 105–116.

8. Недоступ А. А., Ражев А. О., Насенков П. В., Львова Е. Е., Сысенко В. В., Аскаров Д. В., Белозёр И. С. Экспериментальные исследования разноглубинного трала 18/95 м на оз. Виштынецкое // Вопр. рыболовства. 2023. Т. 24 (2). С. 92–98.