Россия

Россия

Исследуется демпфер крутильных колебаний судового дизеля в связи с разработкой цифрового двойника демпфера. Разработка цифрового двойника демпфера крутильных колебаний судового дизеля производится при помощи данных, полученных от системы мониторинга. Использованы правила классификационных обществ, научно-техническая литература в области крутильных колебаний и собственные исследования авторов. Получена структурная модель цифрового двойника с отработкой его функциональных возможностей на демпфере крутильных колебаний главного двигателя MAN B&W 8L27/38 судна проекта Turcas. Сделаны выводы о возможности разработки цифрового двойника демпфера крутильных колебаний судовых дизелей и применения его для оценки технического состояния и назначения остаточного ресурса демпфера. Применение цифрового двойника позволило оценить степень изменения технического состояния и остаточного ресурса для демпфера крутильных колебаний главного двигателя MAN B&W 8L27/38 судна проекта Turcas. В итоге проведения мониторинга крутильных колебаний для машинно-движительного комплекса танкера проекта Turcas дано определение (оценка) техническому состоянию демпфера. Назначенный ресурс по итогам измерений на протяжении 11 дней составляет 7 500 ч работы.

судовые машинно-движительные комплексы, крутильные колебания, система мониторинга, техническая диагностика, демпфер крутильных колебаний, цифровой двойник

Introduction

The development of diagnostic systems has led to the possibility of monitoring the technical condition of not only the main units of marine power plants − main engines and diesel generators, but also their individual important components – fuel equipment, gearboxes, torsional vibration (TV) dampers, turbochargers and others. The importance of the reliability of monitoring the technical condition of dampers is confirmed by the storage of cases of damage to the crankshafts, intermediate and propeller shafts of marine propulsion systems (MPS) due to the development of dangerous TV. Currently, a separate direction in technical diagnostics has appeared in science and technology – the development of digital twins, which are formed by creating an exact virtual copy of the design and behavior model of real objects as part of power plants. The development of digital twins is ensured by an increase in the number of sensors and recording devices that monitor the parameters of real objects and the possibility of modern means of communication for data transmission to digital networks. This makes it possible to obtain not just a computer model of the device, but also to perform technical diagnostics in real time, predict the development of various situations or simulate the occurrence of accidents with complex and expensive installations, including ship installations.

Currently, the technical condition of TV dampers is determined by collapsible and non-collapsible methods based on a regulatory approach. If we talk about the concept of technical diagnostics “in fact”, then a digital twin can serve as a necessary tool for assigning a residual resource or a qualitative assessment of the condition of a real object based on monitoring its parameters. This will avoid unnecessary costs for routine maintenance, if the technical condition of the damper meets the required standards. At the same time, the introduction of an approach to assessing the technical condition “in fact” requires the availability of adequate mathematical models, as well as software and hardware complexes that allow solving the task.

The relevance of the development of a digital twin of a torsional vibration damper

In fact, monitoring of changes in the technical condition of the elements of the ship’s MPS from the effects of TV using non-selective methods is currently possible only for silicone dampers. This is explained by the availability of an appropriate methodology developed by L. V. Efremov [1] and approved by the classification societies - the Russian Maritime Register of Shipping (RMRS) [2], the Russian Classification Society (RCS) [3]. The presence of a large number of data obtained from the TV monitoring system and the possibility of their transmission to a remote computer, allow us to talk about the prospect of developing a digital twin of the TV damper. The digital twin, thus, can be a tool for implementing the concept of maintenance of the damper according to the actual condition, which will reduce the costs of the shipowner and the risks of accidents in comparison with maintenance according to the regulations. According to SS 57700.37-2021 Computer models and modeling. Digital product binaries. General provisions [4] the introduction of digital twins technology at the stage of product operation will make it possible to make informed decisions about the maintenance and repair of the product. Therefore, the concept of “digital twin” (in our opinion) can be fully applied to the TV dampers of marine diesel engines. In practical terms, this allows the technical service of the shipowner to determine the probable residual life of the damper, as well as to draw conclusions about the deviation of its technical condition from normal. Also, the digital twin will allow you to indicate the probable cause of such a deviation – the leakage of silicone liquid or the blade of the flywheel mass due to mechanical damage to the housing or the high viscosity of the filler from wear products.

Development of a digital twin of a torsional vibration damper

A digital twin for a product is defined according to the text of SS 57700.37-2021 [4] as a system consisting of a digital model and two-way information links with the product (if there is a product) and (or) its component parts. According to the classification of digital twins, in the case of a TV damper, it is necessary to use the CD-E type - a digital twin, the filling and functionality of which is determined during the implementation of the product operation stage.

A necessary component for the development of a digital twin is software, which must have the appropriate verification and certification.

According to SS 57700.37-2021 [4]: verification is a confirmation that the computer modeling software performs the preparation of the output data, calculations and processing of the results of such calculations in accordance with the specified mathematical model; validation is a confirmation that the computer modeling software in the declared field of application is adequate with a given degree of accuracy, performs the preparation of initial data, calculations and processing of the results of such calculations. Verification of computer simulation software is a prerequisite for its subsequent implementation.

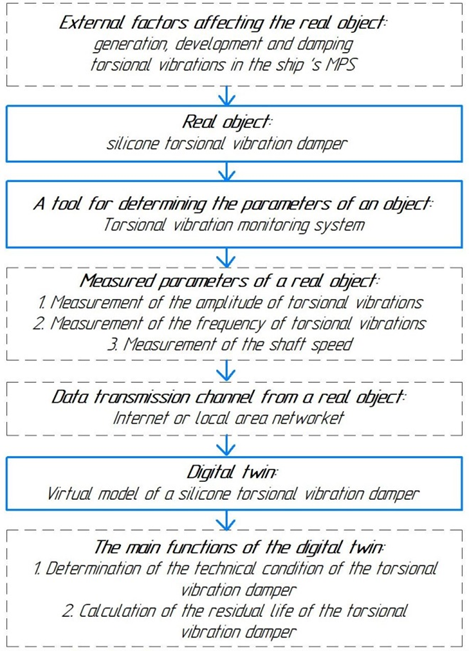

The principles of the development and creation of “digital twins” in industry and technology are described in the sources [5-10], and are also developed by such domestic and foreign firms as: Siemens, ABB, IBM, General Electric, JSC Rotec, JSC VNIIAES, LLC Productive Technological Systems and others. All specialists and firms pay attention to the necessary condition for the functioning of a digital twin - the presence of a stable connection between a virtual model and a real object for data transmission. Since specialists invest quite a lot of components in the concept of “digital twin” and form them according to their own schemes, we will give the author’s scheme for developing a digital twin of the TV damper of a marine diesel (Fig. 1).

Fig. 1. Diagram of the development of a digital twin of a silicone TV damper of a marine diesel

As can be seen from this scheme, the ultimate goal of the proposed digital twin of the damper is to assess its technical condition and assign a residual resource based on periodic measurements of the parameters of TV occurring in the ship’s MPS. Such a technology is currently used for periodic torsiography, however, the use of a digital twin (provided that data is received from the monitoring system) will help to make an assessment with shorter time intervals and, accordingly, more reliably.

The described procedure is implemented by Geislinger for dampers of its own production, however, the technology is the know-how of the company and does not have an open code for its implementation [11, 12].

External factors affecting the real object

As external factors that affect the silicone damper and influence it, it is possible to indicate: generation, development and damping of the cruise oscillations in the ship’s MPS.

Real object

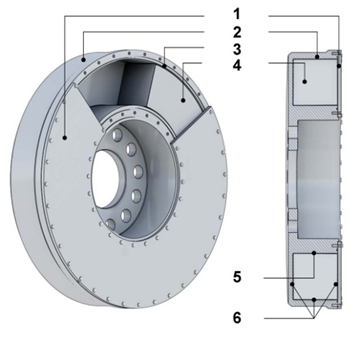

The real object in this case is a silicone damper mounted on a diesel engine. If we consider its typical design (Fig. 2) [13], then the main elements are: the body, the flywheel mass and the filler – silicone fluid.

The principle of operation of the silicone damper is well known and described in many scientific and technical works [1, 13-17], but, it will be more important to consider issues related to the change in its technical condition. Failures and damage to the damper will occur for the following reasons: the flywheel mass is jammed due to an increase in the viscosity of the silicone liquid from the accumulation of wear products; filler leakage through leaks; wear of the flywheel surfaces and the damper housing; damage to the mounting bolts of the damper attachment to the crankshaft of the engine. An example of defects in silicone dampers from “Hasse & Wrede” is shown in Fig. 3 [18].

Fig. 2. Silicone damper “Geislinger” Vdamp: 1 – lid;

2 – housing; 3 – seal; 4 – flywheel; 5 – support surface;

6 – cavity for filling with silicone liquid

a b

c d

Fig. 3. Example of defects in silicone dampers from “Hasse & Wrede”:

a – suspension of the damper flywheel due to leakage of silicone fluid;

b – increasing the viscosity of the silicone liquid to the state of suspension;

c – damage to the surfaces of the flywheel mass of the silicone damper;

d – damage to the surface of the silicone damper housing

A tool for determining the parameters characterizing the state of the object

The author’s TV monitoring system is a tool for measuring the necessary parameters and transmitting data [19, 20]. It allows you to measure and transmit parameters such as: the frequency of rotation of the shaft; the frequency and amplitude of TV, stresses in the strain gauge shaft.

Data transmission channel

Both a wireless network (Wi-Fi, GPRS, etc.) and a wired network (Ethernet) can serve as a data transmission channel if the operation of the digital twin will be carried out directly on the ship. For example, during the control strain gauge, setting up and calibration of the monitoring system, the data will be transmitted to the laptop via the USB or RS interface.

Digital twin

A digital model of a silicone damper in the range of tasks indicated by us should have a mathematical model for assessing the technical condition and calculating the residual resource. The mathematical model of the digital twin will be based on the methodology of L. V. Efremov [1] and given in the rules of the RMRS [2] and RCS [3], as well as on the classical method of calculating the parameters of torsional oscillations (matrix method or the method of chain fractions of A. P. Terskikh). Let’s consider how it is possible to assess the technical state of the damper using a TV monitoring system.

The necessary parameters for the practical assessment of the technical condition of the damper according to the rules of the RMRS [2] and RCS [3] will be: the actual resonant rotational frequency for the corresponding oscillation order; the actual frequency of the motor form oscillations; the actual amplitude of the harmonic component oscillations; the actual total amplitude of the oscillations. The following parameters are taken as reference parameters: the calculated frequency of free oscillations of the motor form; the resonant frequency of rotation; the amplitude of the harmonic component of the oscillations and the tangential stresses from it at the resonant frequency of rotation; the total amplitude of the oscillations and other parameters.

Note that the sources [1-3] provide detailed methods for assessing the technical condition of the silicone damper during routine torsion grading and we will not give them in this article.

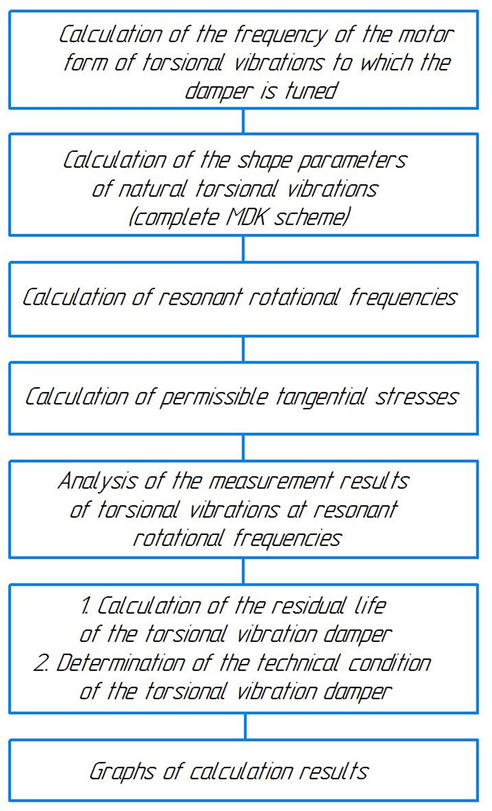

The obtained algorithm of the digital twin of the damper was implemented in the MS Excel program (Fig. 4) in relation to the damper of the main engine of the ship of the Turcas project, using data obtained by the author’s model of the TV monitoring system during tests on the ship. The description of the experiment on the model of the monitoring system on the ship of the Turcas project is given in the work of the authors [19]. It should be noted that the vessel’s MDK includes the following elements: the main engine MAN B&W 8L27/38 (with a rated power of 2 720 kW and a rotation speed of 800 min–1); the Vulkan Vulastik-L-3010 coupling; gearbox AMG28 model 48VO22; spacer shaft; propeller shaft; adjustable pitch propeller; valogenerator.

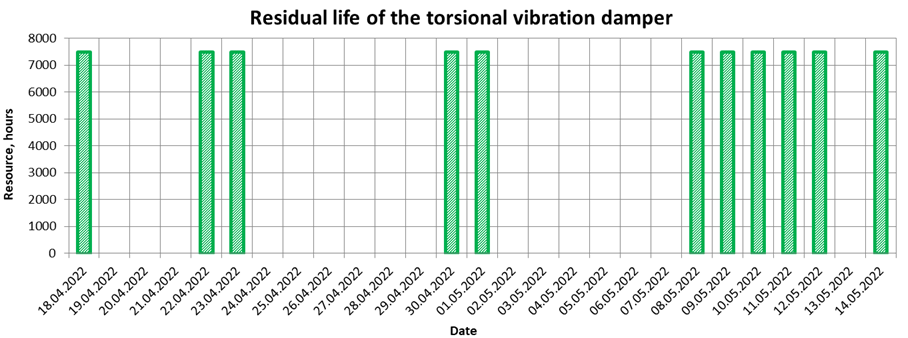

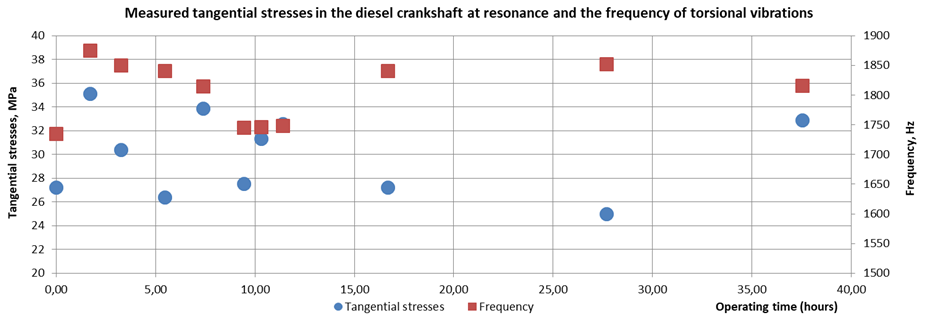

The obtained results of the implementation of the “digital twin” of the TV damper of the main engine of the tanker of the Turcas project are shown in Fig. 5, 6. The measured parameters from the model of the TV monitoring system during its operation on the ship were transmitted by forming a file on the system memory card and transmitting it by e-mail. When processing the data, the participation of the tensogram obtained at the resonant rotational speed of the crankshaft 445 min–1, that is, with fluctuations of the 4th order, was analyzed. This frequency corresponds to the oscillations of the main order of the motor form and the damper is adjusted to it for operation with maximum efficiency. The frequency of the motor waveform for MPS was calculated to be 1 788 Hz. As a novelty, it is proposed to consider not only the permissible stresses, but also the stresses that indicate the effectiveness of the damper. According to the rules of the RMRS [2], the ability to reduce the stress level from TV to 85% of the permissible ones is taken as an efficiency criterion.

Required according to SS 57700.37-2021 Computer models and modeling. Digital twins of products. General provisions [1] verification of the software of the proposed digital twin of the damper is confirmed by its compliance with the mathematical model given in Annex 38 to the manual on technical supervision of vessels in operation of the RMRS [2], and validation is ensured by the adequacy of the results obtained.

According to the results of TV monitoring for 11 days, the technical condition of the TV damper corresponded to the qualitative assessment of “good”, and the residual resource was estimated at 7 500 hours of operation. The obtained constancy of the results is quite predictable, since the operating time during monitoring was only 37.5 hours, which does not significantly change the technical condition of the damper, provided its gradual failure (degradation), and not sudden. At the same time, the obtained results on the maximum tangential stresses and the frequency of resonant oscillations allowed us to construct their graphical dependences on the operating time (Fig. 7).

Fig. 4. Algorithm of operation of the digital twin of the TV damper mounted on the crankshaft of a diesel engine

Fig. 5. Graphical representation of the development of stresses from resonant TV in the crankshaft

of the main engine of the vessel of the Turcas project

Fig. 6. Graphical representation of the value of the residual life of the main engine damper

of the vessel of the Turcas project

Fig. 7. Stresses in the crankshaft and the frequency of TV of the motor form depending on the operating time

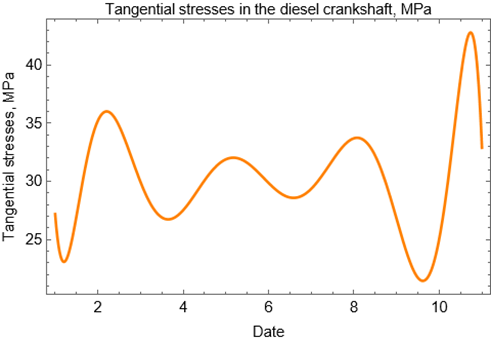

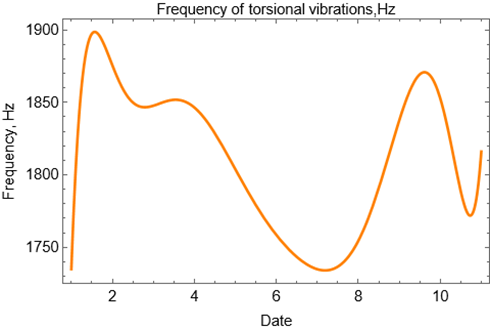

Since the MS Excel program does not have the ability to interpolate data to obtain a trend line function with high accuracy, an additional analysis was carried out in the Wolfram Mathematica software product with the construction of graphs and the output of functions for stresses in the diesel crankshaft and oscillation frequency. As a result, the tangential stresses change function with R2 = 0.87 has the form shown in Fig. 8, and the frequency change graph with R2 = 0.98 in Fig. 9.

Fig. 8. Graph of tangential stresses changes in the diesel crankshaft by monitoring days

Fig. 9. Graph of fluctuation frequency changes by monitoring days

Discussion

As can be seen from the results obtained, the maximum stresses in the measurement process differed from the average value of 29.94 MPa within 17.2%. The oscillation frequency differed from the average value of 1 806 Hz within 3.9%. Such deviations can be explained by the variance of the measured values, as well as by the influence of unaccounted factors, which are quite numerous when carrying out real measurements of torsional fluctuations.

The obtained dependences do not have a clear pattern, therefore, it was not possible to obtain a stable trend with predicting the development of stresses and frequency changes in such a short period of monitoring time, which was also confirmed by an attempt to use functions based on data interpolation for long-term forecasting. Therefore, in order to determine adequate mathematical dependencies for determining the rate of change of stresses and the frequency of oscillations, much longer tests are required. The ideal option for obtaining a complete picture of the development of stresses over the life cycle of a damper would be to monitor its parameters from the moment of manufacture until it is written off, however, such an experiment requires a lot of time and labor. The most likely solution to the problem of obtaining empirical dependencies can serve as monitoring for the period between routine torsiografations of the MPS, in this case, during the assigned 7 500 hours of operation. A similar problem can also be solved with the help of a digital twin of a damper, provided that an adequate mathematical model of the change in the frequency of oscillations and tangential stresses from the time of its operation is obtained. However, as experts point out, this task is quite complicated, since such dependencies will depend on the type of damper, its design, the type of MPS in which it is located, the operating mode of the diesel engine, etc. Therefore, the solution of such a problem is the development of the technology of the digital twin of the TV damper and is the subject of further research by the authors of the article, the direction of which is indicated, including in the author’s works [21, 22].

Separately, it should be noted that when introducing an indicator of its effectiveness as an additional criterion for assessing the technical condition of the damper, on some of the days there was an increase in the tangential stresses level to 86-90% of the permissible ones. However, this did not lead to exceeding the permissible norms according to the rules of the RMRS.

Conclusion

1. The digital twin of a silicone damper can become a tool for moving from a routine assessment of its technical condition to an actual approach.

2. The digital twin of the silicone damper makes it possible to assess the technical condition and assign a residual resource with much shorter periods than with routine torsiography, which increases the efficiency of monitoring changes in its technical condition in the direction of deterioration.

3. The results obtained allow us to talk about the dispersion of the measured values, both in terms of tangential stresses and frequency of oscillations, which in general did not affect the final assessment of the residual life of the damper and the qualitative assessment of its technical condition.

4. The development of a digital twin of the TV damper of a particular vessel requires the development and installation of an individual character monitoring system, since the nature of TV and the location of the measuring part of the system significantly depend on the type of MDK and the nature of its operation.

5. Based on the results of monitoring of TV for the MPS tanker of the Turcas project, the technical condition of the damper was determined as “good”, and the life expectancy according to the results of measurements for 11 days is 7 500 hours of work.

1. Ефремов Л. В. Теория и практика исследований крутильных колебаний силовых установок с применением компьютерных технологий. СПб.: Наука, 2007. 276 с.

2. Приложения к руководству по техническому наблюдению за судами в эксплуатации / Российский морской регистр судоходства. СПб.: Изд-во РМРС, 2020. 409 с.

3. Р.043-2016. Оценка работоспособности силиконовых демпферов крутильных колебаний судовых двигателей внутреннего сгорания / Российское классификационное общество. М.: Изд-во РКО, 2016. 66 с.

4. ГОСТ 57700.37-2021. Компьютерные модели и моделирование. Цифровые двойники изделий. Общие положения. М.: Изд-во Рос. ин-та стандартизации, 2021. 15 с.

5. Шведенко В. Н., Мозохин А. Е. Применение концепции цифровых двойников на этапах жизненного цикла производственных систем // Науч.-техн. вестн. информ. технологий, механики и оптики. 2020. Т. 20. № 6. С. 815-827.

6. Галацевич В. В. Создание цифровых МЭМС двойников // Приборостроение-2022: материалы 15-й Междунар. науч.-техн. конф. (Минск, 16-18 ноября 2022 г.). Минск: Изд-во БНТУ, 2022. С. 430-431.

7. Массель Л. В., Массель А. Г., Щукин Н. И., Цыбиков А. Р. Разработка цифрового двойника ветровой электро-станции: постановка задачи и проектирование // Информ. и матем. технологии в науке и упр. 2022. № 1 (25). С. 79-90.

8. Ерошенко С. А., Хальясмаа А. И. Технологии цифровых двойников в энергетике // Электроэнергетика глазами молодежи - 2019: материалы Х Междунар. науч.-техн. конф. (Иркутск, 16-20 сентября 2019 г.). Иркутск: Изд-во Ир-НИТУ, 2019. C. 55-58.

9. Подобный А. В. Методика создания цифровых двойников трансформаторов на основе корректируемых по ре-зультатам эксперимента имитационных моделей: автореф. дис. ... канд. техн. наук. Иваново, 2022. 20 с.

10. Цифровой двойник авиационного двигателя в DYNAMICS R4. Научно-технический центр роторной динамики вращающихся машин «Альфа-Транзит», 2023. 8 с.

11. Geislinger Monitoring System. Catalog, 2018. 34 p.

12. Ohorn H., Thalhammer A., Mohr H. Torsional vibration monitoring of large container vessel propulsion train // Program Torsional Vibration Symposium. Salzburg: Schwingungstechnischer Verein., 2022. 52 p.

13. VDamp Catalog Version 1.4. Geislinger. 2016. 13 с.

14. Родин П., Мельников Б. Диагностика демпферов // Судоходство. 1998. № 10. С. 70-71.

15. Hafner K. E., Maass H. Torsionsschwingungen in der Verbrennungskraftmaschine. Springer-Verlag, 1985. 434 p.

16. Сахаров А. Б. Защита судовых валопроводов от крутильных колебаний. М.: Транспорт, 1988. 115 с.

17. Гоц А. Н. Крутильные колебания коленчатых валов автомобильных и тракторных двигателей: учеб. пособие. Владимир: Изд-во ВлГУ, 2008. 200 с.

18. AVM Diesel. Sales & Service of Hasse & Wrede. 2015. 2 p.

19. Горбачев М. М., Покусаев М. Н. Результаты испытаний прототипа системы мониторинга крутильных колебаний на судне «Иван Поддубный» // Наука и практика - 2022: материалы Всерос. междисциплин. науч. конф. (Астрахань, 10-15 октября 2022 г.). Астрахань: Изд-во АГТУ, 2022. С. 271-274.

20. Pokusaev M., Gorbachev M., Sibryaev K., Ibadullaev A. Problems of diagnostics of technical condition of torsional vibration dampers of modern marine diesel engines // Recent Achievements and Prospects of Innovations and Technologies. 2023. N. 2 (2). P. 137-145.

21. Горбачев М. М., Покусаев М. Н., Сибряев К. О., Ибадуллаев А. Д. Работоспособность механических демпферов крутильных колебаний судовых двигателей внутреннего сгорания // Вестн. Астрахан. гос. техн. ун-та. Сер.: Морская техника и технология. 2022. № 1. С. 35-41.

22. Горбачев М. М., Покусаев М. Н., Сибряев К. О., Ибадуллаев А. Д. Оценка технического состояния силиконо-вых демпферов крутильных колебаний машинно-движительных комплексов судов // Вестн. Астрахан. гос. техн. ун-та. Сер.: Морская техника и технология. 2022. № 4. С. 67-72.