Россия

Россия

Проведен анализ преимуществ и недостатков установки пружинных демпферов крутильных колебаний в составе современных судовых дизелей. Рассматриваются актуальные проблемы, связанные с применением пружинных демпферов для судовых машинно-движительных комплексов, в частности отсутствие систематизации научных сведений о конструкции пружинных демпферов, статистики их распространенности в судовых дизелях, анализ случаев поломок. Отмечено, что в настоящее время не существует методики оценки технического состояния пружинных демпферов, в отличие от рекомендованной Российским морским регистром судоходства и используемой методики для силиконовых демпферов. Разборная диагностика технического состояния пружинных демпферов является крайне затруднительной и затратной для судовладельца. Установлено, что большая часть судов, находя-щихся в эксплуатации в России, устарела, происходит постепенный процесс их модернизации и замены, что приводит к появлению на смену устаревшим главным двигателям типа Г60, Г70 (6ЧРН 36/45), SKL NVD, 6ЧН18/22, 3Д6 (6ЧН 15/18) других, новых иностранных дизелей производства компаний Wartsila (Финляндия), Caterpillar (США), Volvo - Penta (Швеция), Scania (Швеция), Henan Diesel Engine Industry Co., Ltd (Китай) и т. д., которые имеют в своем составе новые по конструкции демпферы фирм Geislinger (Германия), Hasse & Wrede (Германия), STE - Schwingungstechnik (Германия), Holset (Англия), Caterpillar (США) и др. Диагностика демпферов современных дизелей – это новое направление для отечественной морской индустрии, которое требует пересмотра как технологических процессов работы с такого рода оборудованием, так и подготовки квалифицированных специалистов. Изучение конструкционно-эксплуатационных особенностей пружинных демпферов современных дизелей позволит накопить необходимый объем научно-технической информации для создания в России основ производства эффективных конструкций и развития двигателестроения в целом.

пружинные демпферы, крутильные колебания, современные судовые дизели, конструкционно-эксплуатационные особенности, установка демпферов

Introduction

Today, the strategic objectives of the development of the Russian state are to increase its technological sovereignty, as well as to solve import substitution issues in all clusters of the economy [1, 2]. These problems can be clearly demonstrated by the example of the operation of spring dampers of torsional vibrations (SD TV), in particular the diagnosis of their technical condition. The problem of damping the TV of shaft lines of diesel engines is very important for the durability and operational safety of the entire propulsion complex (PC) of the vessel. The lack of high-quality technical operation of dampers can cause a violation of the navigation safety due to the fact that the service life and reliability of such elements as propeller, intermediate, crankshafts, gearboxes, couplings, etc. depend on them. In this regard, the rules of both national (the Russian Maritime Register of Shipping (RMRS) [3], the Russian Classification Society (RCS)) [4] and foreign (Det Norske Veritas & Germanischer Lloyd (DNV GL) [5, 6]; Bureau Veritas (BV) [7]; Registro Italiano Navale (RINA); Lloyd’s Register (LR), etc.) classification societies prescribe the requirements for the mandatory calculation and measurement of TV.

Most of the vessels that are currently operating in Russia are outdated, and there is a gradual process of their modernization and replacement, which leads to replacing the morally and physically obsolete main engines such as Г60, Г70 (6ЧРН 36/45), SKL NVD, 6ЧН18/22, 3Д6 (6ЧН 15/18) by new foreign diesel engines manufactured by Wartsila (Finland), Caterpillar (USA), Volvo - Penta (Sweden), Scania (Sweden), Henan Diesel Engine Industry Co., Ltd (China), etc., which have in their composition new dampers by Geislinger (Germany) [8], Hasse&Wrede (Germany) [9], STE - Schwingungstechnik (Germany) [10], Holset (England) [11], Caterpillar (USA) and other companies.

Diagnostics of dampers of modern diesel engines is a new direction for the domestic marine industry and requires a revision of both the technological processes of working with such equipment and the training of qualified specialists.

The use of SD for marine PC is associated with the following problems that require an up-to-date solution:

1. The design of SD is more complicated than that of silicone. There are several versions of SD: with plate elements; with spring elements; with a combined design - mechanical and hydraulic parts, etc. This requires scientific systematization of information about the design of SD, analysis of statistics of their prevalence in marine diesel engines, analysis of breakdowns and factors that can lead to damage to the damper.

2. Currently, there is no methodology for assessing the technical condition of SD, in contrast to the recommended by RMRS and used for silicone dampers. Spring dampers manufacturers offer the shipowners to disassemble and assess the condition of spring elements every 10,000 - 15,000 hours of operation. This is not an easy task. The procedure may require the special tool base, involvement of the specialists from the manufacturer or repair specialists and the RMRS or RCS inspectors to approve assessing the technical condition of the damper. Torsiography can become an alternative and simpler solution for assessing the technical condition of SD and assigning a residual resource before their repair or replacement.

3. The period between 10,000 - 15,000 hours assigned by the SD manufacturers between inspections can be used for intensive operation of a vessel in one year, an example is the operation of the support vessels “Langepas” and “Kogalym”, whose main engines produced more than 10,000 hours in the period from summer 2019 to autumn 2020 [12-15]. This indicates that the procedure of opening and assessing the technical condition of the SD can be very frequent and costly for the shipowner.

4. The widespread use of foreign SD TV and their installation on modern marine diesels leads to a reduction in the number of domestic dampers that were previously used for diesel engines of the Г60, Г70 type and, accordingly, dependence on foreign manufacturers.

The study of the structural and operational features of the SD of modern diesel engines will allow to accumulate the necessary amount of scientific and technical information to create the foundations of domestic production of effective structures and to start up building engines as a whole.

Marine diesels with SD TV

1. Application of SD for MAN diesel engines.

Using SD in marine diesels began quite a long time ago, for example, for diesel engines of the MAN company (Germany) model K6Z57/80. Currently, SD is installed on MAN B&W S70MC6, 7S50MC engines (Fig. 1), L35MC6 and other models [16].

Fig. 1. General view of the MAN B&W 7S50MC engine

Technical parameters of the MAN B&W 7S50MC engine:

- Number of cylinders: 7 pcs.;

- Cylinder diameter: 500 mm;

- Piston stroke: 2,000 mm;

- Rated power: 11,060 kW;

- Rated speed: 127 rpm;

- Average effective cycle pressure P: 19.0 bar;

- Specific fuel consumption: 171 g/kWh.

These engines are installed on ships of the “Aframax” class tanker type with a displacement of up to 100,000 tons. The most common brands of damper for these engines are MAN, Geislinger.

2. Application of SD for MAK diesel engines.

Spring dampers is also used in common diesels of the MAK (CAT) company [17], for example, in MAK 8M25 engines (Fig. 2) with a rated power of 2,640 kW. These engines are used on vessels providing drilling platforms, for example, “Kogalym”, “Langepas”.

Fig. 2. General view of the MAK 8M25 engine

MAK 8M25 engines have the following technical characteristics:

- Rated power: 2,640 kW;

- Rated speed: 750 rpm;

- Cylinder diameter: 255 mm;

- Piston stroke: 400 mm;

- Number of cylinders: 8.

Geislinger spring dampers are used on these diesels.

3. Application of SD for Wartsila diesel engines.

The most popular series of marine engines with SD TV is the Wartsila (Finland) model 6L20 engine [18] (Fig. 3) with a power of 1,200 kW, which is installed on ships of the RST, RSD projects with a displacement of 7,000-9,000 tons, which are currently being built to replace the outdated ships “Volgodon” series, “Volgoneft”, “Omskiy” and others.

Fig. 3. General view of the Wartsila 6L20 engine

Analysis of the advantages and disadvantages of SD TV

Advantages of SD. The advantages of the SD of modern marine diesel engines include the following:

Greater work efficiency.

The peculiarity of the SD design is the presence

of a combined mechanical and hydraulic part of the damping area - for this purpose oil is supplied to the damper from the engine under pressure, as a result it is located between the packages of spring plates and converts vibrations into thermal energy, heating the oil. This complicates the design of the damper, but allows to use the advantages of both SD and hydraulic dampers. It combines two types of friction - mechanical and hydraulic, i.e. it has greater efficiency than the silicone one and can work in in the plants with a large number of nodal forms of torsional vibrations or, more simply, with a large number of the ship power plant (SPP) elements. Some foreign sources write about high-energy torsional vibrations, which are just reduced by using such combined dampers.

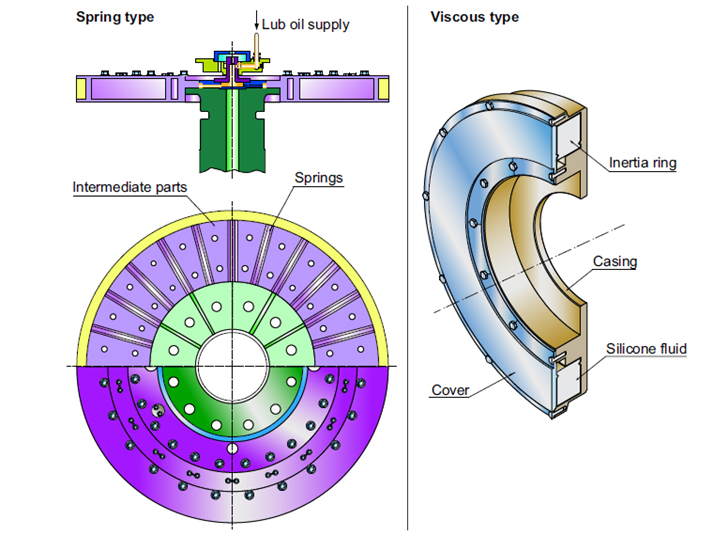

The company WinGD (Winterthur Gas & Diesel Ltd.), which is a subsidiary of the company Sulzer Diesel Engine for its marine diesel engines model X40-D (with a capacity of 1,135 kW per cylinder, two-stroke diesel) allows installing both silicone and SD. At the same time, the company recommends doing this in the following cases. Installation of silicone viscous dampers.

Where it is necessary to reduce torsional vibrations with low energy, a viscous damper can be installed (Fig. 4). In some cases, the calculation of torsional vibrations shows that additional cooling is required for a viscous damper. In such cases, the layout must comply with the recommendations of the damper manufacturer and the wing design department. The viscosity

of the silicone filler in these dampers should be checked periodically.

Fig. 4. Variants of dampers for installing on the marine diesel engines WinGD model X-40D

Installation of SD.

For high-energy torsional vibrations that may occur, for example, on 5-6-cylinder engines, a SD can be installed with its additional adjustment to increase the damping effect (Fig. 4).

The SD must be supplied with oil from the engine lubricating oil system. To install a spring-type damper, the use of a damper control system is mandatory (first of all, monitoring the pressure and oil flow in the damper is meant). The peculiarities of using SD instead of silicone ones include using them, among other things, on dual-fuel diesels, which is caused by some change in the nature

of TV when changing fuel from liquid to natural gas. Geislinger uses SD in the units where the number of resonant frequencies of the TVs is large and the amplitudes cannot be reliably reduced using silicone dampers (which this company also produces). A long-term stability of the damper properties. In classical silicone dampers, wear products accumulate after prolonged operation, which leads to increasing viscosity of the silicone fluid of the damper, and, consequently, to a change not only in the efficiency of reducing the amplitudes of TV, but also to

a change in the frequency of vibrations, which ultimately can cause jamming of the flywheel mass of the damper and loss of its efficiency. In SD with a flow system and using oil under pressure such a problem doesn’t appear, which allows to talk about the stability of SD properties for a long time.

Fine tuning. Fine tuning of the damper is possible when it is installed on a specific SPP by using springs with different stiffness or changing their number in the damper. Therefore, the effectiveness of the damper is determined by its design, shape and number of springs. Thus, the torsion system is rebuilt, and the most critical resonance is eliminated. If the outer part of the damper vibrates with respect to the inner, the leaf springs bend, and the engine oil is pumped from one chamber to another under pressure. This reduces the relative motion

of the two parts and thus dampens the TV.

Maintainability of the damper. Maintainability of the damper is related to the fact that the springs wear out to a greater extent, and the damper housing to a lesser extent, so that the repair is provided by replacing spring packages. Proven manufacturing and operation technology. In addition to using the SD on the two-stroke and four-stroke marine diesel engines, they are used in the diesel locomotive engines, industrial diesel engines, drilling rigs etc. This allows manufacturers to accumulate theoretical and practical experience in their calculations, manufacturing and repair, which improves their design and reliability. Installation on modern diesel engines. A relative merit of SD is their use on modern marine diesels such as Wartsila 6L20, Wartsila 9L20, MAK 8M25 and others, which proves a tendency to complicate this device and increase versatility of its type, complexity and operating conditions of the SPP [19].

Disadvantages of SD

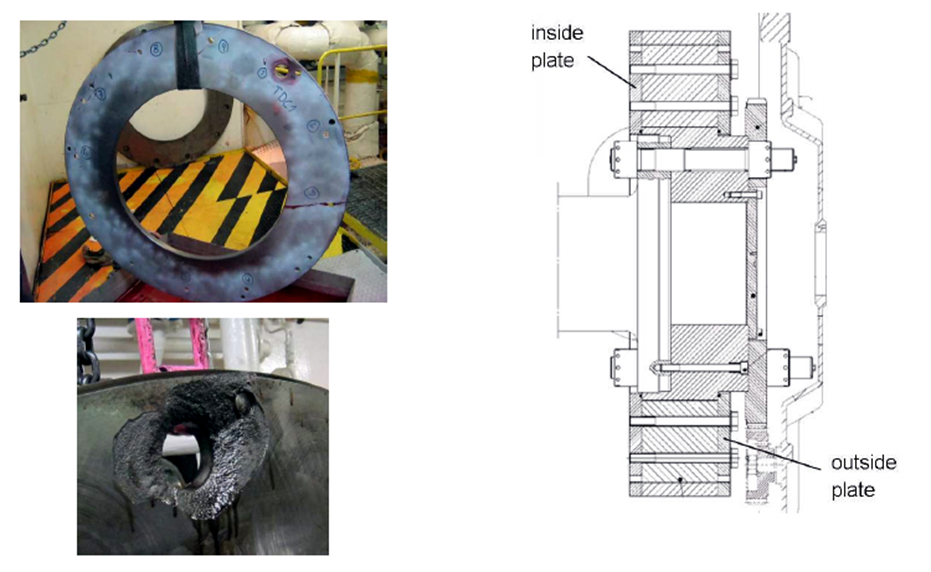

The disadvantages of SD are the following facts. Complexity of the design. Based on the fact that silicone dampers have maximum simplicity, SD, on the contrary, have a large number of structural elements, which can lead to unexpected breakdowns of dampers not only due to the spring wear, but for example, as stated in the official press release of MAN, when operating TV dampers on the two-stroke diesels for more than 80,000 hours, cracks and destruction of SD covers can occur in the places of the fixing bolts (Fig. 5).

Fig. 5. Destruction of the cover of the SD MAN

The company recommends regular visual inspection of both side plates of the dampers. The experience of MAN showed that cracks were found in the holes and threaded holes of the side plates. Therefore, the damper must be dismantled, which in total takes about 3-4 days. MAN Diesel & Turbo recommends changing the inner and outer side plates after 80,000 - 100,000 hours of operation to ensure safe and reliable operation of the engine. It is strongly recommended to carry out the inspections, as these cracks can lead to serious subsequent damage to the TV damper.

The complexity of the design leads to an increased cost of SD. However, as the SD manufacturers assure, no costs are required for their maintenance before 90,000 hours of operation. In fact, this is not true, because a damper requires periodic diagnostics of the technical condition of the springs, which will require the disassembly of the damper.

Providing additional control of the damper. The complexity of the design leads to the need to ensure specific requirements during their operation - in particular, monitoring the pressure at the entrance to the combined damper, oil quality control and the thermal condition of the damper. As noted by the Geislinger manufacturers, the thermal power released by the SD can reach 50 kW, and the oil consumption through it makes up to 12 m3/h. Complexity of defect detection and diagnostics of damper elements.

The simplicity of maintainability does not entail the simplicity of its defect - that is, the process of replacing spring packages may not be complicated and performed directly on the ship, but the process of accessing spring packages may require removing the damper from the diesel engine, the use of special tools and devices, as well as the presence of specialists from the manufacturer, the inspector of the classification society to ensure guarantees of further effective operation of the damper. The key disadvantage is the lack

of the possibility of non-selective diagnostics of the technical condition of SD, unlike silicone ones. Manufacturing companies such as Geislinger allow diagnostics of the technical condition based on torsiography, both during the initial installation of dampers and during its operation, but do not replace the need to open and inspect spring packages to assess their wear.

Conclusions

1. The key problems of import substitution, as well as increasing the level of technological sovereignty of Russia, affect not only the manufacture of domestic machines, mechanisms, installations and equipment, but also the development of their own methods for calculating their structural and operational parameters, including methods for assessing the technical condition of objects and assigning their residual life to the limit state.

2. The method of non-selective diagnostics is part of the big problem of technological sovereignty

of Russia in the field of design, operation and repair

of SD TV marine diesel engines.

3. Diagnostics of the technical condition of SD TV is a new direction for the domestic marine industry and requires a revision of both the technological processes of working with such equipment and the training

of qualified specialists.

4. According to the analysis, the main advantages of SD TV are: high efficiency; stability of the damper properties for a long time; fine tuning, maintainability, proven manufacturing and operation technology, installation on modern diesel engines. 5. The disadvantages of SD TV are: the complexity of the design, high cost, the need to provide additional control, the complexity of defect detection and diagnostics of elements.

6. The study of the structural and operational features of the SD of modern diesel engines will allow accumulating the necessary amount of scientific and technical information to create the foundations of domestic production of efficient structures and the development of engine building as a whole.

1. Стратегия развития внутреннего водного транс-порта Российской Федерации на период до 2030 года (утв. распоряжением Правительства Российской Федерации от 29.02.2016 № 327-р). URL: https://www.garant.ru/products/ipo/prime/doc/71240936/ (дата обращения: 12.03.2023).

2. Стратегия развития судостроительной промышленности до 2035 года (утв. распоряжением Правительства РФ от 28.10.2019 № 2553-р). URL: http://government.ru/docs/38218 (дата обращения: 12.03.2023).

3. НД № 2-030101-009. Приложения к руководству по техническому наблюдению за судами в эксплуатации. СПб.: Изд-во РМРС, 2023. 415 с.

4. Руководство Р.043-2016. Оценка работоспособности силиконовых демпферов крутильных колебаний судовых двигателей внутреннего сгорания. М.: Изд-во РКО, 2016. 66 с.

5. DNV GL. Rules for Classification. Part 4. Systems and components. Chapter 2. Rotating machinery, general, 2015. 56 p.

6. DNV GL. Rules for Classification. Part 4. Systems and components. Chapter 3. Rotating machinery - drivers, 2016. 76 p.

7. BV. Rules for the Classification of Steel Ships. Part C: Machinery, Electricity, Automation and Fire Protection, 2022. 694 p.

8. Geislinger. Damper Catalog. Version 15.9, 2020. 50 p.

9. Viscous dampfer. Instruction manual. Hasse & Wrede. Mohriner, 1997. 13 p.

10. STE Schwingungstechnik. Maintenance Instruction for Viscous Torsional Vibration Dampers (VTD), 1996. 6 p.

11. Metaldyne Viscous Dampers. Formerly Simpson. Holset Viscous Damper, 2014. 4 p.

12. Окончательное заключение по результатам торсиографирования машинно-движительного комплекса судна обеспечения «Лангепас». Астрахань: ИЦ MTS; АГТУ, 2019. 59 с.

13. Окончательное заключение по результатам торсиографирования машинно-движительного комплекса судна обеспечения «Лангепас». Астрахань: ИЦ MTS; АГТУ, 2020. 51 с.

14. Окончательное заключение по результатам торсиографирования машинно-движительного комплекса судна обеспечения «Когалым». Астрахань: ИЦ MTS; АГТУ, 2019. 55 с.

15. Окончательное заключение по результатам торсиографирования машинно-движительного комплекса судна обеспечения «Когалым». Астрахань: ИЦ MTS; АГТУ, 2020. 51 с.

16. MAN B&W. General-Engine operating instructions. Type S50MC-C7, 2009. 393 p.

17. MAK M25. General-Engine operating instructions. Type M25, 1999. 1966 p.

18. Руководство по эксплуатации двигателя Wartsila 6L20. 2013. 432 с. URL: https://com-alfa.ru/pdfviewer/6l20pdf_oZXBfft.pdfenc.pdf (дата обращения: 12.03.2023).

19. Сибряев К. О., Покусаев М. Н., Горбачев М. М., Ибадуллаев А. Д. Работоспособность механических демпферов крутильных колебаний судовых двигателей внутреннего сгорания // Вестн. Астрахан. гос. техн. ун-та. Сер.: Морская техника и технология. 2022. № 1. С. 35-41.