Russian Federation

Russian Federation

Russian Federation

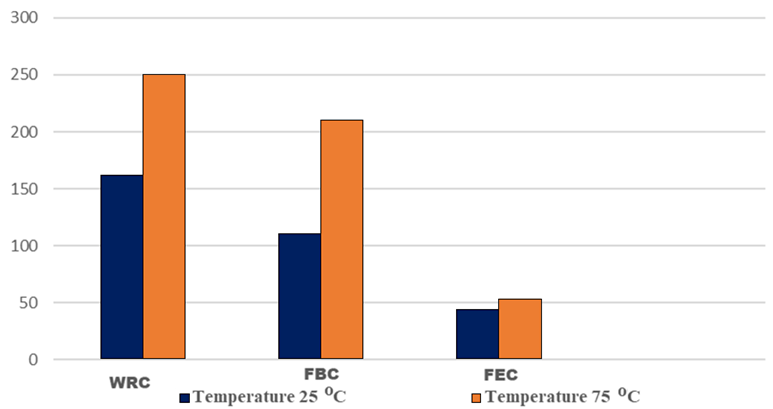

The article presents the results of studying the functional and technological properties of the dried product “KalmaKS” made from the skin of Commander squid. Technological properties such as water-retaining capacity (WRC), fat-binding capacity (FBC), fat-emulsifying capacity (FEC), critical gel concentration (CGC), foaming capacity (FC), foam stability (FS), and protein solubility in water have been analyzed as well. The determination of WRC, FBC and FEC has been carried out at different temperatures of the system “KalmaKS – water”: 25 ± 2 and 75 ± 2 °C. It has been ascertained that the product from squid’s skin has a high WRC, reaching 162% at a temperature of 25 °C, it has also been proven that “KalmaKS” binds water significantly better when the temperature rises to 75 °C. The research has shown high values of “KalmaKS’s” FBC (110%); it has been found out that an increase in temperature leads to an increase of this index to a level of 210%. The product made from squid’s skin has a fairly high (44.5%) FEC, slightly increasing with increasing temperature (up to 53%). High indices of CGC (30%) and FS (80%), low values of FC (3%), as well as high indicators of protein solubility (44.5%) have been ascertained. There has been made the conclusion about the possibility of using the product from squid’s skin, “KalmaKS”, in the production of food produce as a structure regulator with water-retaining, fat-binding and gel-forming properties.

functional and technological properties, Commander squid, squid’s skin, dried food product, water-retaining, fat-binding and gel-forming properties, structure regulator

Introduction

The goal of the development strategy of the Russian Federation’s fish industry complex for the period up to 2030 is the provision for the average per capita consumption of fish and fish products with the total amount of 22-27 kg/p.c. annually. To achieve the goal, it is necessary to increase the operational efficiency and depth of water biological resources processing, which can be done by means of production flexibility and management of new product output, by nonwaste production and product quality increase. Providing the population with ecologically clean and safe produce can be achieved by a deeper usage of raw material resources.

An important direction in the development of the fish processing industry is the introduction of non-waste technologies providing for the high degree of raw materials' potential used, with the maximum extraction of valuable substances from the waste products. In particular, the depth of processing such a valuable resource as squid, remains at present at a low level – not higher than 65%, unchanging for the last decades, which testifies to the low degree of hydrobionts processing and the absence of innovations in the fish processing industry. Waste disposal methods used by fish processing enterprises have an environmental burden on the ecosystem, worsening its condition.

Fish processing enterprises of the Kamchatka Territory, engaged in squid production, face the most acute issue of its deep processing. The efforts of the scientific community both in the Russian Federation and abroad are aimed at solving the problem of increasing the depth of processing. Taking into account ample evidence of significant biological value of the waste from processing squid which is caught by fishing enterprises in Kamchatka, the use of this waste in food production technologies seems to be a highly promising and relevant area. It should be noted that the highest concentration of high added-value compounds, such as proteins, essential amino acids, lipids, polyunsaturated fatty acids, vitamins, minerals, is often found in parts of marine organisms that are not used for food purposes and are simply discarded.

Commander squid Berryteuthis magister, a representative of the Gonatidae family, is the only species of cephalopods in the waters of Russia, developed on a large scale. The skin yield in mechanical cutting of the B. magister squid can reach 10% of the raw product mass. With the existing catch volumes, the possible yield of integumentary tissues is 3 thousand tons, which is a significant underutilized raw material resource, not inferior to food raw materials in terms of its chemical and biological characteristics.

It seems a well-grounded approach based on the use of squid processing waste, in particular, skin, as a structure-regulating, enriching and flavoring additive. The integumentary tissues of squids contain a large number of stromal proteins – collagen and elastin, the amount being 4 times more than that in muscle tissues [1-3]. It is advisable to use leather products, in particular, dried ones, in the production of new types of food products.

At present, there is a rather limited number of developments aimed at deep processing of waste from cutting squid, in particular, skin [1, 4-9]. E.g. scientists have proposed a technology of obtaining collagen from the skin of squid. Squid by-products can be sent to the production of hydrolysates, biologically active additives, as well as technical products. There is a way to obtain fat from the entrails of squid (liver and gonads), the fat content of which reaches 10-30% [10]. A technology of obtaining fat from squid liver has been developed, and a method for obtaining fat from squid liver by heating it in water is also known [11]. A method for the production of dietary supplements for food of hypocholesterolemic and hemostimulating action “Squid oil” is proposed [12]. There is a technology of obtaining lecithin from squid gonads [13]. A technology has been developed for the production of additives from waste from commercial squid species [1].

There is a profound interest in the processing of offal from squid all over the world. E.g. studies have been carried out on the possibility of using protein hydrolysates from squid offal as a taste-functional ingredient [14]. The functional protein hydrolyzate from dried squid head has been found suitable for use in food products, especially as an antioxidant. Ezquerra-Brauer et al. showed that protein hydrolysates prepared from by-products of the giant squid (Dosidicus gigas) had high biological activity [15]. Giménez et al. reported that the antioxidant activity of gelatin films could be improved by adding squid hydrolysates, although this also affects the mechanical properties [16]. Cuevas-Acuña et al. included hydrolysates obtained from squid gelatin skin by enzymatic hydrolysis into chitosan films and found out that the resulting films had increased antifungal activity [17]. The studies carried out by Abdelmalek et al. [18] showed that gelatin obtained from the skin of the squid Loligo vulgaris could form a thermoreversible gel; it exhibited the capacity to foam and emulsify, as well as water-binding and fat-retaining properties.

Thus, the development of cost-effective produce from squid processing waste is a promising scientific line. Based on the research conducted at Kamchatka State Technical University (KamchatGTU), a technology of the production of the dried product “KalmaKS” from squid skin [19], considered as a promising natural food dresser, has been developed. It is established that the new product has attractive organoleptic characteristics, as well as high biological value, due, among other things, to a high protein content, largely consisting of collagen. Probably, the “KalmaKS” has the properties of a structure regulator, which is indirectly evidenced by the data on the chemical composition (in particular, the high content of proline and hydroxyproline) [20].

In studying the functional and technological properties of the dried food product from the skin of the squid, the “KalmaKS”, for the first time, the presence of water-retaining, fat-binding and gel-forming properties was experimentally established.

Research objective – the analysis of the prospects for the use of dried food product from the skin of the commander's squid, “KalmaKS”, in food technologies as a structure regulator.

The study of the functional and technological properties of dried food product “KalmaKS” made from the skin of Commander squid.

Materials and methods

The major object of the research is the technology of obtaining dried food produce from the skin of the Commander squid, “KalmaKS”. The food product “KalmaKS” has been obtained at the Department of Food Production Technologies of the Federal State Budgetary Educational Institution of Higher Education “KamchatGTU” from the skin of the Commander squid Berryteuthis magister by drying at the temperature of 45-55 °C for 7 hours, followed by grinding to the particles’ size of not more than 0.25 mm. The subject of the research is dried produce from the skin of the Commander squid, “KalmaKS”.

The sampling of the dried produce from squid’s skin has been carried out under Federal standard 31339 “Fish, non-fish objects and the products from them. Acceptance rules and sampling methods”.

To determine the functional and technological properties (FTP) of the dried product “KalmaKS” made from the skin of Commander squid, its water-retaining capacity (WRC), fat-binding capacity (FBC), fat-emulsifying capacity (FEC), critical gelationg concentration (CGC), foaming capacity (FC) , foam stability (FS), and protein solubility in water, have been studied.

Water-retaining capacity has been determined by the amount of water that the protein can bind and retain during centrifugation [21, 22]. To this end, 10 cm³ of water was added to 1 g of the product tested and heated to 20 °C, followed by infusion, then it was centrifuged for 5 min, and the free water was carefully poured off. The WRC was calculated from the difference between the mass of the test-tube with the hydrated sample after water drain and the initial mass of the sample.

The FBC has been determined by the amount of oil absorbed per mass of the dried product [23]. To this end, 2 g of the product tested was placed in glass centrifuge test-tubes, and from 0.5 to 2.5 g of vegetable oil was added at the interval of 0.5 g. The contents of the test-tubes were mixed, whereupon the test-tubes with the preparation’s suspensions were kept in the thermostat at the temperature of 74-76 °C for 15 min. After thermostating, the test-tubes were cooled with cold water to room temperature and centrifuged for 15 min. The maximum amount of added oil, at which no separation of the oil phase was observed during the test, in terms of 1 g of the preparation, was taken as the value of the FBC.

To determine the FEC, there was used a method according to which a weighed sample of the tested product in the amount of 7 g, mixed with 100 cm³ of distilled water, was suspended for 1 min. Then 100 cm³ of sunflower oil was added to the mixture and emulsified for 5 min. Thereafter the emulsion was poured equally into four calibrated centrifuge test-tubes and centrifuged for 5 min. The FEC was characterized as the ratio of the volume of the emulsion layer to the total volume of the mixture of oil and suspension [24].

To evaluate the gelling properties of the squid skin product, the analysis of the critical concentration of gel formation has been carried out [25, 26]. A series of solutions was prepared with a step of solids concentration of 5%, 10 test-tubes. The resulting suspensions were homogenized for 5 min, until a homogeneous consistency was obtained, and transferred into glass test-tubes. The test-tubes were placed in a thermostat and kept for 15 min at a temperature of 74-76 °C. After heating, the test-tubes were cooled with cold water to room temperature, placed in a refrigerator, where they were kept for 16-18 hr at the temperature of 4-6 °C. Lead balls with an average mass of 0.64 g were placed on the surface of the suspension and kept for 2 hr at the temperature

of 4-6 °C. The gel formation was fixed by the position of a lead ball. As the critical concentration of gel formation, there was taken the concentration of the tested preparation corresponding to the sample in which the gel formation was noted.

The FC has been determined, according to the method proposed by the Department of Plant Proteins and Biotechnology of the All-Russian Research Institute of Fats, by the height of the foam formed after shaking a sample of the product ground with water [24].

A weighed portion of the test-sample was placed in a beaker, 25 cm³ of distilled water was added, whereupon the portion was triturated until a homogeneous mass was obtained. Then the mass was transferred into a measuring cylinder with a capacity of 500 cm³ with a sealing plug, washing off the residue in the glass with distilled water, and bringing the total volume of liquid in the cylinder up to 300 cm³. In the course of 1 min, each sample was shaken, the cylinder being in the horizontal position (60 shakes). The amount of foam was measured by its height above the liquid level. The stability of the foam has been assessed by the capacity to keep its foam structure, to maintain its volume for a certain period of time, until complete destruction [27, 28].

Protein solubility in water has been determined under Federal standard 7636 “Fish, marine mammals, marine invertebrates and products of their processing. Methods of analysis” by a method based on the extraction of the water-soluble fraction from the protein, dehydration of the insoluble part by centrifugation, evaporation, drying and its weight determination.

The statistical treatment of the findings has been done on the basis of calculating average values and arithmetic error. To treat the received data and to draw graphical dependence, the operational system Microsoft Windows 2016 and the software Microsoft Office 2016 (incl. Word 2016, Excel 2016), have been used. In this paper, arithmetic values are represented by average values; their assurance (Р) is 0.95 at the confidence interval (CI) of ± 10%.

Results and discussion

The correctness of conducting technological processing and the quality of the finished produce is largely determined by the properties of the raw material, in particular, by its FTP. The knowledge of the FTPs of dried product from squid’s skin will determine the prospects for its use in the course of technological processes, it will bring the understanding of the “KalmaKS” influence on the quality and stability of food products structure. Functional properties are usually understood as physicochemical characteristics that determine the behavior of an ingredient when it is added to food products, and provide the desired structure, technological and consumer properties of the finished product [21, 22, 29]. The most important functional properties include solubility, water-retaining, gelling, emulsifying and FC. These characteristics reflect the influence of substances on the formation of food produce’s consistency, determine the level of its digestibility and consumer properties.

An important property of products is the capacity to bind and retain moisture. This capacity is characterized by a whole range of FTP [21, 30]. Equally important FTPs include properties that make it possible to bind fats, to form foams, gels, fat emulsions. There are a number of methods for determining FTP, such as WRC, FEC, FBC, CGC, FC, FS, and protein’s solubility in water; the methods have been used to determine these characteristics in the “KalmaKS” product. In order to study the effect of temperature on the FTPs, the determination of WRC, FEC and FBC has been carried out at different temperatures of the “KalmaKS” system – the water: 25 ± 2 and 75 ± 2 °C.

The functional and technological characteristics of the product “KalmaKS” from the skin of the Commander Islands squid are presented in the figure and in the Table.

Functional and technological characteristics of the dried product from squid’s skin,

“KalmaKS” depending on the temperature of the system “KalmaKS – water”

Functional and technological characteristics of the dried product from squid’s skin “KalmaKS”, %

|

Name of the index |

Index value |

|

Critical gelling concentration (CGC) |

30.0 |

|

Foaming capacity (FC) |

3.0 |

|

Foam stability (FS) |

80.0 |

|

Protein’s solubility in water |

44.5 |

The quality of a product largely depends on the capacity of its components to retain water during processing and storage, and therefore one of the most significant functional properties is WRC. Water-retaining capacity characterizes the properties of products to absorb and retain water due to the presence of hydrophilic groups in them [14]. The index studied is determined by the amount of water that the protein can bind and retain during centrifugation.

The knowledge of the WRC makes it possible to design the composition of products with specified rheological and water-retaining properties, to maintain a stable structure throughout the entire shelf life, and to increase the yield of the final product. In the production of food products, based on WRC value, it is possible to calculate the amount of the ingredient in the receipt, which provides the necessary rheological properties, to stabilize the structure of the product during storage, and to reduce losses during processing [31, 32]. The analysis of the results of the research carried out allows us to state that the product from squid’s skin has a high WRC, reaching 162% at the temperature of 25 °C; it has also been found that “KalmaKS” binds water much better when the temperature rises to 75 °C (see the figure). Obviously, such a high level of “KalmaKS’s” WRC is due to the significant content of protein in it, capable of hydration and swelling. The research results show the possibility of using the developed dried product as a water-retaining ingredient in food receipts.

The FBC of products is connected with the adsorption of fat due to hydrophobic groups that promote fat binding. The studies have shown high values of “KalmaKS’s” FBC (110%); it should be noted that an increase in temperature leads to an increase in this index to a level of 210% (see the Figure). The high FBC of the product from squid’s skin is obviously due to its finely ground structure, which allows the binding of free fat, as well as to the good accessibility of hydrophobic parts.

The analysis of the results obtained in studying FEC has shown that “KalmaKS” has a fairly high (44.5%) FEC, slightly increasing with increasing temperature (up to 53%). Obviously, significant WRC and FBC affect the thickening and stabilizing properties of the new product, which, in their turn, contribute to significant FEC values (see the figure).

The critical gelation concentration (CGC) characterizes the maximum level of substance hydration and is defined as the minimum concentration of a gelling agent, at which the entire surrounding liquid binds up to form a gel. Sufficiently high CGC values (30%), presented in the table, testify to a significant gelling capacity of the product from squid’s skin with a high content of proteins and, in particular, collagen, which has a positive effect on the value of the index studied [7].

To study the foaming properties of substances, the amount of foam obtained and its stability are determined [6]. The results obtained showed the “KalmaKS’s” low FC (3%), indicating the impossibility of obtaining significant foam masses when using the developed products (see the table). At the same time, the studies of the FS have shown that the formed foam keeps its structure for a long time and does not fall off – the FS reaches 80%, which is probably due also to the high protein content in the product.

The authors have conducted the study of the solubility of the “KalmaKS's” protein, showing the high capacity of the new product’s proteins to dissolve (44.5%), which testifies to the preservation of its native properties and the rationality of the selected technological modes of processing raw material (see the Table).

Conclusion

The results of studying the functional and technological properties of “KalmaKS” have demonstrated that the product from squid’s skin can be used in food receipts as a water-retaining, fat-binding and gel-forming component. Together with a high content of biologically active substances, as well as marked attractive taste, smell and color, the data obtained make “KalmaKS”

a promising natural ingredient in food products that makes it possible to regulate the structure, to increase the nutritional value, and also to impart new organoleptic characteristics.

1. Bashtovoy A. N. Issledovanie othodov pererabotki promyslovogo kal'mara i lososevyh s cel'yu polucheniya kormovoy produkcii // Izv. TINRO. 2008. T. 154. S. 384-389.

2. Neklyudov A. D. Pischevye volokna zhivotnogo proishozhdeniya. Kollagen i ego frakcii kak neobhodimye komponenty novyh i effektivnyh pischevyh produktov // Prikladnaya biohimiya i mikrobiologiya. 2003. T. 39. № 3. S. 261-272.

3. Neklyudov A. D., Ivankin A. N. Kollagen: poluchenie, svoystva i primenenie: monogr. M.: GOU VPO MGUL, 2007. 336 s.

4. Kozyreva O. B., Sluckaya T. N. Obosnovanie usloviy proteoliza pokrovnyh tkaney golovonogih mollyuskov s cel'yu polucheniya pischevyh emul'siy // Izv. TINRO. 1999. T. 125. S. 338-343.

5. Kucherenko N. A. Nauchnoe obosnovanie i razrabotka tehnologii sushenyh formovannyh produktov iz kal'mara: dis. … kand. tehn. nauk. Vladivostok, 2011. 182 s.

6. Stepancova G. E. Obosnovanie ispol'zovaniya ot-hodov ot razdelki kal'marov dlya polucheniya kormovoy muki i zhira: dis. … kand. tehn. nauk. Kaliningrad, 2002. 154 s.

7. Bashtovoy A. N. Tehnologiya kormovyh dobavok na osnove biomodifikacii othodov, poluchennyh pri razdelke gidrobiontov: dis. … kand. tehn. nauk. Vladivostok, 2014. 186 s.

8. Boeva N. P. Sostoyanie i perspektivy razvitiya proizvodstva kormovoy muki iz gidrobiontov // Rybnaya promyshlennost'. 2004. № 3. S. 14-15.

9. Patent RU № 2195130S1. Sposob polucheniya belkovogo gidrolizata / Gmyrya I. F.; opubl. 27.12.2002.

10. Patent RU № 2241026C1. Sposob polucheniya zhira iz pecheni kal'mara / Kas'yanov S. P., Bocharov L. N., Akulin V. N., Yakush E. V.; opubl. 27.11.2004.

11. Kizevetter I. V. Tehnologiya obrabotki vodnogo syr'ya. M.: Pisch. prom-st', 1976. 425 s.

12. Vareha E. Yu., Chernyak Yu. D. Innovacii - formula uspeha, ili na puti v svetloe rybnoe buduschee // Rybprom: tehnologii i oborudovanie dlya pererabotki vodnyh bioresursov. 2008. № 1. S. 6-14.

13. Kalenik T. K., Tabakaeva O. V. Biotehnologicheskie sposoby modifikacii othodov pererabotki gidrobiontov // Vestn. biotehnologii i fiziko-himich. biologii im. Yu. A. Ovchinnikova. 2006. T. 2. № 4. S. 33-34.

14. Sukkhown P., Jangchud K., Lirjaroenphon Y., Pirak T. Flavored-functional protein hydrolysates from enzymatic hydrolysis of dried squid by-products: Effect of drying method // Food Hydrocolloids. 2018. V. 76. P. 103-111.

15. Ezquerra-Brauer J. M., Aubourg S. P. Recent trends for the employment of jumbo squid (Dosidicus gigas) by-products as a source of bioactive compounds with nutritional, functional and preservative applications: A review // Journal of Food Sciience and Technology. 2019. N. 54. P. 987-998.

16. Giménez B., Estaca J. G., Alemán A., Guillén M. C. G., Montero M. Improvement of the antioxidant properties of squid skin gelatin films by the addition of hydrolysates from squid gelatin // Food Hydrocoll. 2009. N. 23. P. 1322-1327.

17. Cuevas-Acuña D. A., Plascencia-Jatomea M., San-tacruz Ortega H. d. C., Torres-Arreola W., Ezquerra-Brauer J. M. Development of Chitosan/Squid Skin Gelatin Hydrolysate Films: Structural, Physical, Antioxidant, and Antifungal Properties // Coatings. 2021. N. 11. P. 1088.

18. Abdelmalek B. D., Gomez-Estaca J., Sila A., Mar-tinez-Alvarez O., Gomez-Guillen M. C., Chaabouni-Ellouz S., Ayadi M. A., Bougatef A. Characteristics and functional properties of gelatin extracted from squid (Loligo vulgaris) skin LWT // Food Science and Technology. 2016. N. 65. P. 924-931.

19. Blagonravova M. V., Samohin A. V. Obosnovanie tehnologicheskih parametrov sushki pokrovnyh tkaney kal'mara s ispol'zovaniem infrakrasnogo izlucheniya // Vestn. Kamchat. gos. tehn. un-ta. 2021. № 57. S. 30-43.

20. Blagonravova M. V., Volkov V. S., Samokhin A. V. Chemical composition of food product KalmaKS produced from dried squid skin // Vestnik of Astrakhan State Technical University. Series: Fishing industry. 2022. N. 3. R. 123-128.

21. Renzyaeva T. V., Tubol'ceva A. S., Ponkratova E. K., Lugovaya A. V., Kazanceva A. V. Funkcional'no-tehnologicheskie svoystva poroshkoobraznogo syr'ya i pischevyh dobavok v proizvodstve konditerskih izdeliy // Tehnika i tehnologiya pischevyh proizvodstv. 2014. № 4. S. 43-48.

22. Skripko O. V. Izuchenie funkcional'no-tehnologicheskih svoystv belkovo-vitaminnyh i belkovo-uglevodnyh dobavok na osnove soi // Vestn. Krasnoyar. gos. tehn. un-ta. 2020. № 3. S. 150-156.

23. Børresen T. Improving seafood products for the consumer. Cambridge: Woodhead Publishing Limited, 2008. 612 r.

24. Belyaev A. G. Tehnologiya pischevyh produktov zhivotnogo proishozhdeniya lechebnogo, special'nogo i profilakticheskogo naznacheniya: metodicheskie ukazaniya po vypolneniyu laboratornyh rabot. Kursk: Izd-vo Yugo-Zapad. gos. un-ta, 2017. 16 s.

25. Svetlakov D. B. Metodiki opredeleniya FTS karraginana // Izv. vuzov. Pischevaya tehnologiya. 2004. № 2-3. S. 111-112.

26. Storublevcev S. A. Ocenka geleobrazuyuschey sposobnosti gidrolizovannoy formy kollagena // Innovacionnaya nauka. 2021. № 11-2. S. 33-34.

27. Ivanova S. A. Penoobrazuyuschie svoystva koncentrata belkov obezzhirennogo moloka // Tehnika i tehnologiya pischevyh proizvodstv. 2018. T. 49. № 4. S. 12-21.

28. Falunina Z. F., Evnickaya I. A., Vinogradova L. A. Laboratornyy praktikum po obschey tehnologii pischevyh produktov. M.: Pisch. prom-st', 1978. 271 s.

29. Minevich I. E. Nauchnoe obosnovanie i razrabotka nauchno-prakticheskih osnov tehnologiy glubokoy pererabotki semyan l'na s polucheniem ingredientov dlya sozdaniya produktov zdorovogo pitaniya: dis. … d-ra tehn. nauk. Tver', 2022. 382 s.

30. Zabashta N. N., Nesterenko A. A. Ispol'zovanie biotehnologicheskih priemov, pischevyh dobavok v tehnologii myasnyh produktov (chast' 2): metodicheskie ukazaniya k vypolneniyu laboratornyh rabot. Krasnodar: Izd-vo KubGAU, 2019. 32 s.

31. Zabodalova L. A. Nauchnye osnovy sozdaniya produktov funkcional'nogo naznacheniya: ucheb.-metod. posobie. SPb.: Izd-vo Universiteta ITMO; IHiBT, 2015. 86 s.

32. Ol'hovaya L. P., Petrova L. D. Tehnologiya kombinirovannoy strukturirovannoy rybnoy massy na osnove produktov pererabotki soi // Nauch. tr. Dal'-rybvtuza. 2007. № 19. S. 257-265.